A device for preventing slipping of roll train transmission and suppressing torsional vibration of four-high rolling mill

A technology of four-high rolling mill and roll system, which is applied in the direction of driving device, back pressure device, and safety equipment of rolls for metal rolling mills, and can solve the problem of slippage between rolls, damage to the surface finish of rolls, unstable torsional vibration of the rolling mill transmission system and other problems to achieve the effect of preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described below through the specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

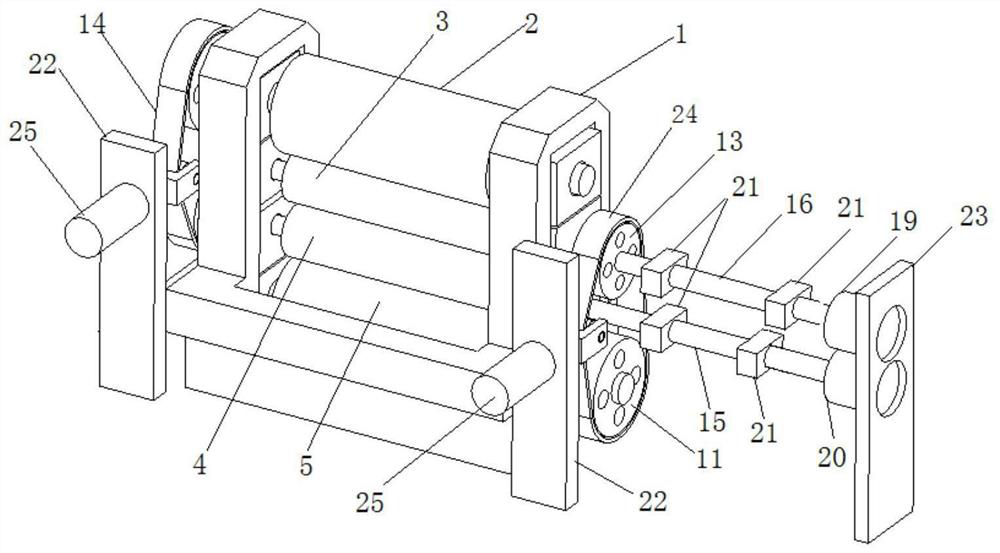

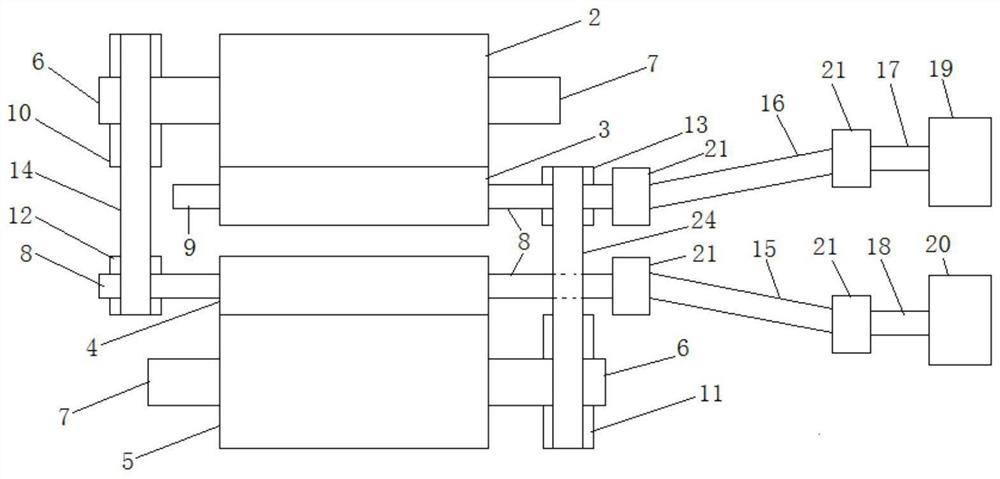

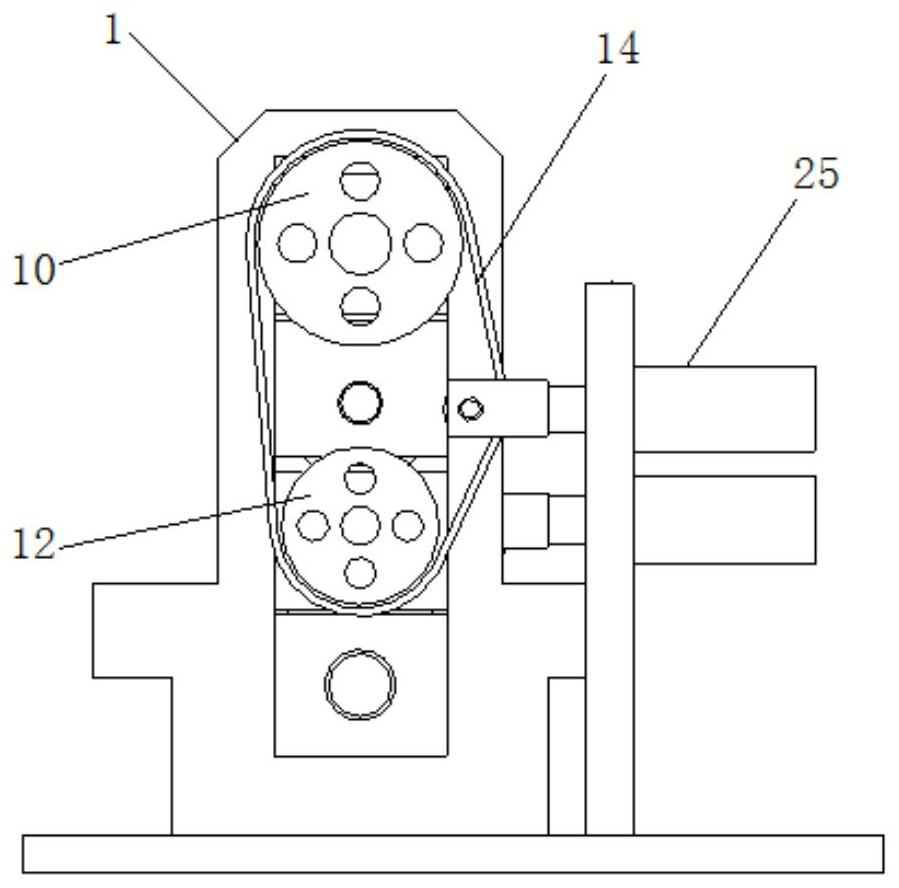

[0020] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown in the figure, a device for preventing the slippage of the roll train and suppressing the torsional vibration of a four-high rolling mill comprises: a rolling mill stand 1, an upper support roll 2, an upper work roll 3, a lower work roll 4, a lower support roll 5, an upper support roll Pulley 10, Lower Support Roller Pulley 11, Lower Work Roll Pulley 12, Upper W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com