Method for welding circuit lead of array element of ultrasonic array ultrasound probe

An ultrasonic array and wire bonding technology, applied in the field of medical devices, can solve the problems of large error, depolarization of piezoelectric ceramics, and limited application range of hot presses, and achieve the effects of good consistency, protection performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

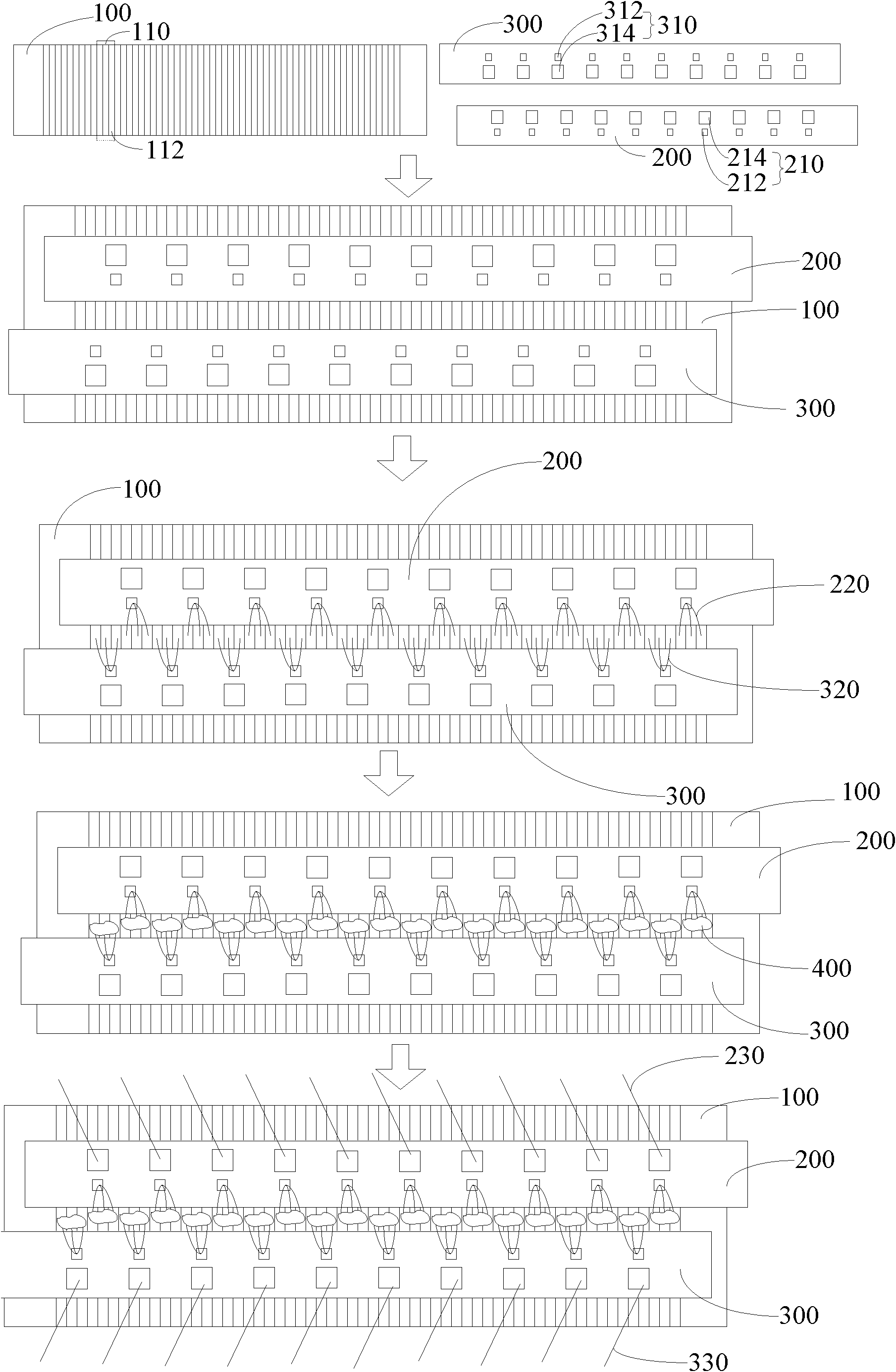

[0019] The method for welding the circuit wires of the ultrasonic array sound head elements will be further described in detail below mainly in conjunction with the accompanying drawings and specific embodiments.

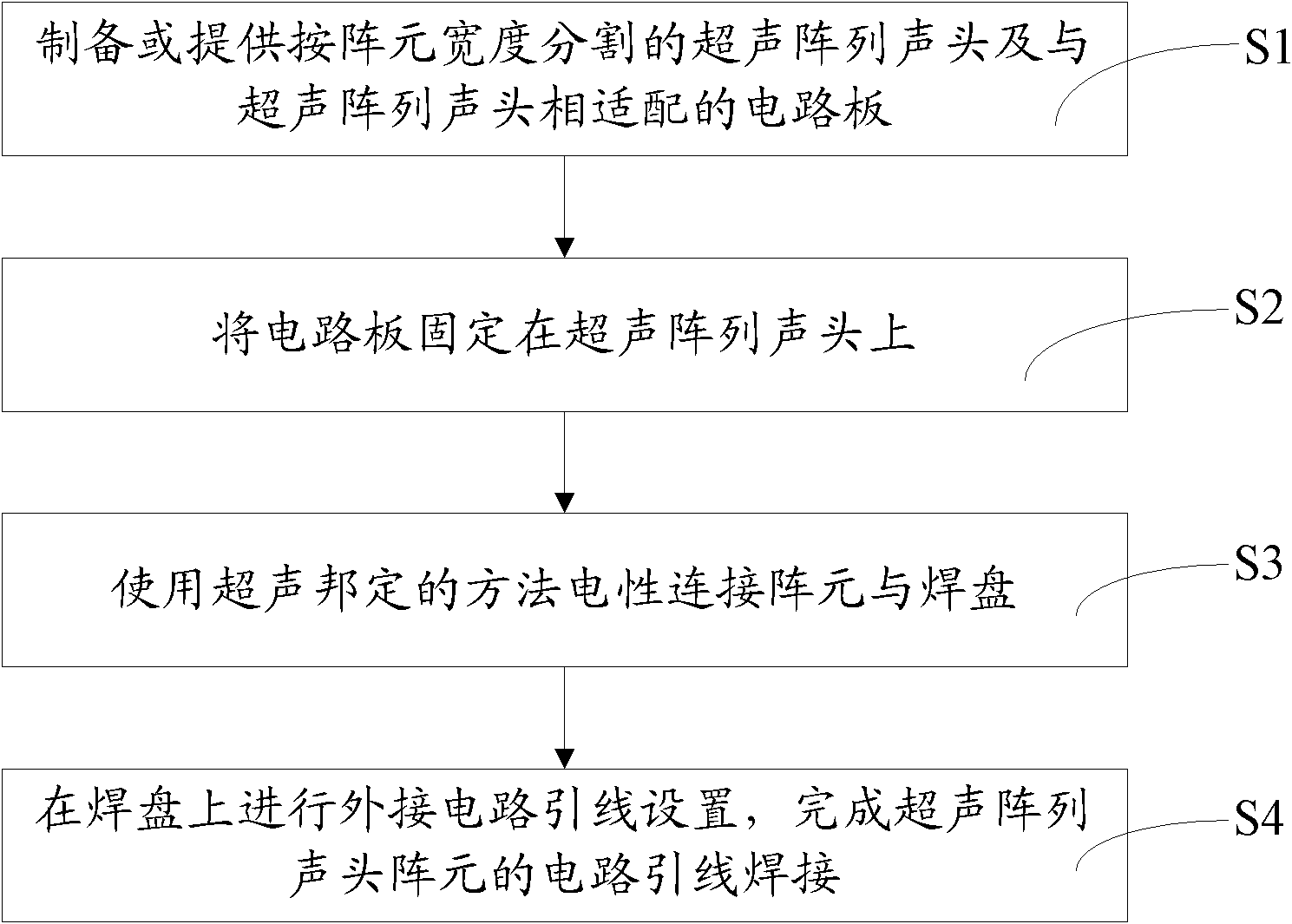

[0020] Such as figure 1 As shown, the circuit wire welding method of an ultrasonic array sound head array element in an embodiment includes the following steps:

[0021] Step S1: Prepare or provide ultrasonic array sound heads divided by array element widths and circuit boards adapted to the ultrasonic array sound heads.

[0022] Ultrasonic array sound head can be ultrasonic convex array, concave array, linear array and phased array sound head, etc. There are multiple equal-width array elements on the ultrasonic array sound head. Wherein, the array element includes a main array element and a sub-array element, and a plurality of sub-array elements constitute a main array element.

[0023] Preferably, the ultrasonic array sound head can be a piezoelectric ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com