Machine tool

一种机床、旋转轴的技术,应用在金属加工机械零件、维护和安全配件、自动控制装置等方向,能够解决颤振抑制困难、工件成品率下降等问题,达到抑制颤振、实现成品率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

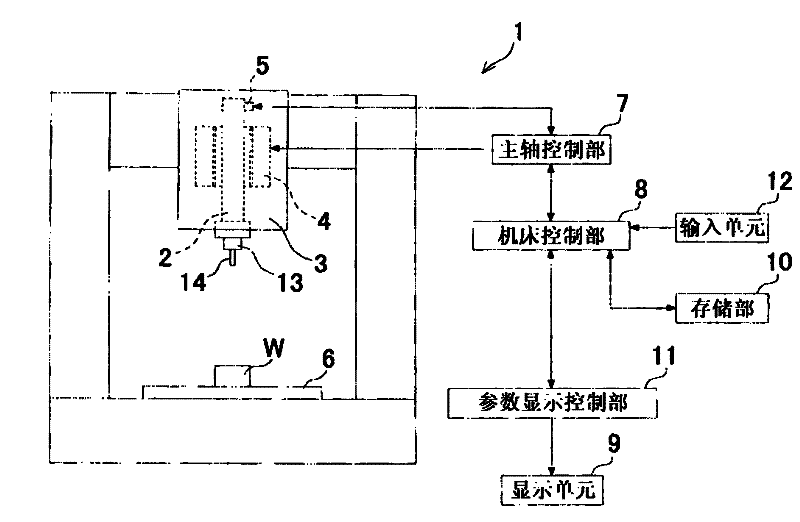

[0024] Hereinafter, a machine tool according to an embodiment of the present invention will be described in detail with reference to the drawings.

[0025] Reference numeral 1 is a machining center having a main shaft 2 as a rotating shaft to which a tool 14 can be attached via a jig 13, and a motor 4 for rotating the main shaft 2 is built in a headstock 3 which supports the main shaft 2 in a rotatable manner. And an encoder 5 for detecting the rotational speed of the main shaft 2 and the motor 4 . In addition, a table 6 on which the workpiece W is placed is provided at a position facing the headstock 3 .

[0026] On the other hand, reference numeral 7 is a spindle control unit for controlling the rotation speed of the spindle 2 or adjusting the electric power supplied to the motor 4 , and is electrically connected to the motor 4 and the encoder 5 . In addition, reference numeral 8 is a machine tool control unit that controls the overall operation of the machining center 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com