Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of performance degradation and difficulty in balancing, increase rigidity, improve performance on ice and snow Performance, the effect of improving handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

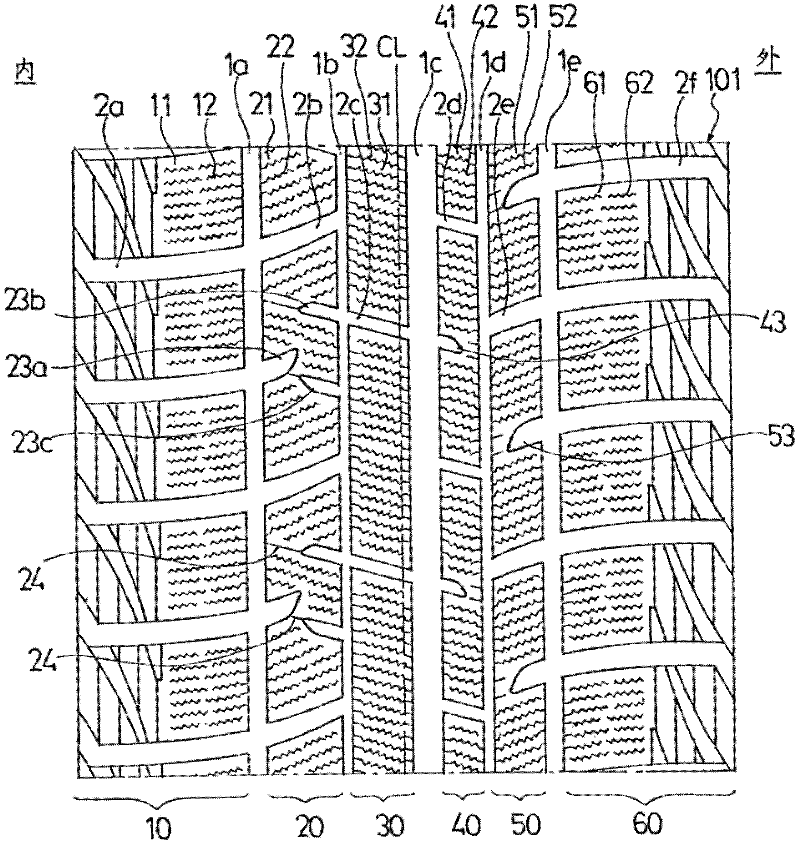

[0065] The tire of Example 1 has image 3 In the tread pattern, the inclination angle θa of the first closed groove 23a is set to -17°, and the inclination angles θb and θc of the second closed grooves 23b and 23c are respectively set to +15°. The tire of Example 2 has Figure 8 The tread pattern has the same pattern as in Example 1, except that the first closed groove 23a is arranged at a position shifted from the transverse groove 2a that defines the blocks 11 of the block row 10 of the shoulder in the tire circumferential direction. structure.

[0066] For comparison, prepare to have the same image 3 Tires of Comparative Examples 1 and 2 with similar tread patterns. That is, the tire of Comparative Example 1 has Figure 10 The tread pattern of each block 21 is provided in each block 21 instead of providing the closed grooves 23a to 23c, and a transverse groove that crosses each block 21 is provided, and each block 21 is subdivided in the tire circumferential direction....

Embodiment 3

[0080] The tire of Example 3 has Figure 7 In the tread pattern, the inclination angle θa of the first closed groove 23a is set to -17°, and the inclination angles θb and θc of the second closed grooves 23b and 23c are respectively set to +15°. The tire of Example 4 has Figure 9 The tread pattern has the same pattern as that of Example 3, except that the first closed groove 23a is arranged at a position shifted from the transverse groove 2a that defines the blocks 11 of the block row 10 of the shoulder in the tire circumferential direction. structure.

[0081] For comparison, prepare to have the same Figure 7 Tires of Comparative Examples 3 and 4 with similar tread patterns. That is, the tire of Comparative Example 3 has Figure 12 The tread pattern of each block 21 is provided in each block 21 instead of providing the closed grooves 23a to 23c, and a transverse groove that crosses each block 21 is provided, and each block 21 is subdivided in the tire circumferential dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com