Online detection system for adhesion of straws to packing boxes

A detection system and packaging box technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems that the straw machine cannot distinguish whether there is a straw or stick the tube on the inverted package, and achieve the effect of solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

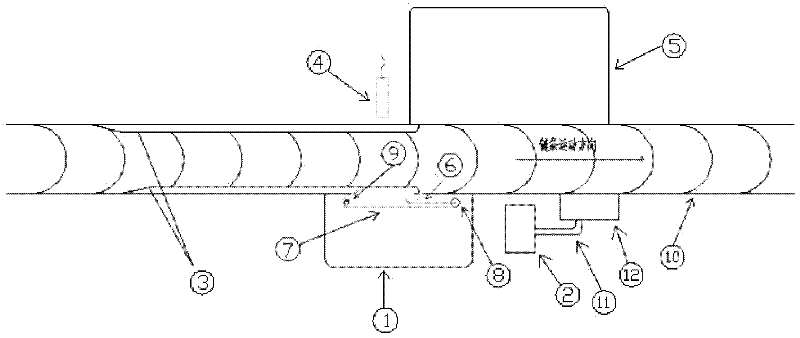

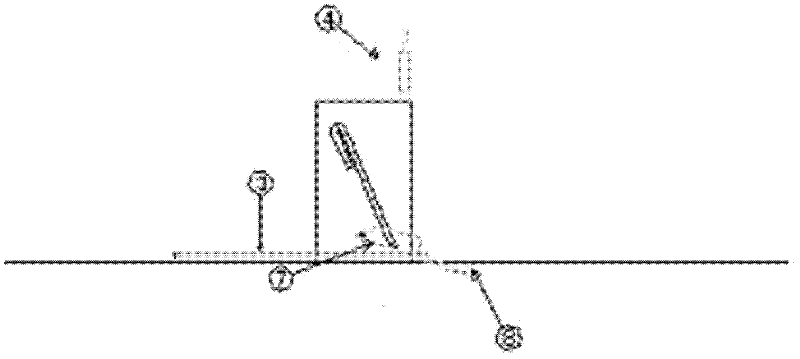

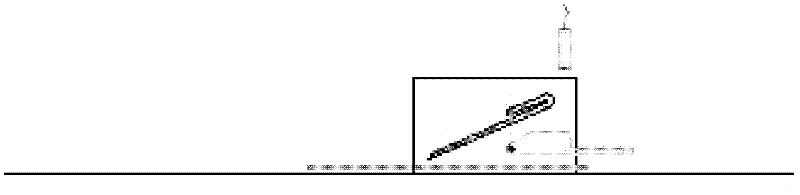

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] The detection system of the present invention is arranged on the chain of milk packaging production, and the detection system includes guide rails 3 arranged on both sides of the chain, and the two sides of the guide rail 3 are oppositely provided with an electric eye 4 and a proximity switch 8, and the proximity switch 8 Connected with the detection sheet 7, the same side of the proximity switch 8 is provided with a solenoid valve 12, a gas pipe 11 connected to the solenoid valve 12 and an electric blowing nozzle 2, and the electric eye 4, the proximity switch 8 and the solenoid valve 12 are controlled by unit control;

[0023] The electric eye detects the milk package. At the same time, the straw on the packaging box is abnormal, and the lower end of the straw cannot touch the detection piece 7 to make it deflect. The proximity switch 8 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com