Phenol inhibition-coupled low temperature short-cut denitrification method

A phenol and short-range technology, which is applied in the field of short-range denitrification process under low temperature conditions, can solve the problem of whether the treatment effect of new pollution is stable, and achieve the effect of ensuring sewage treatment performance and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

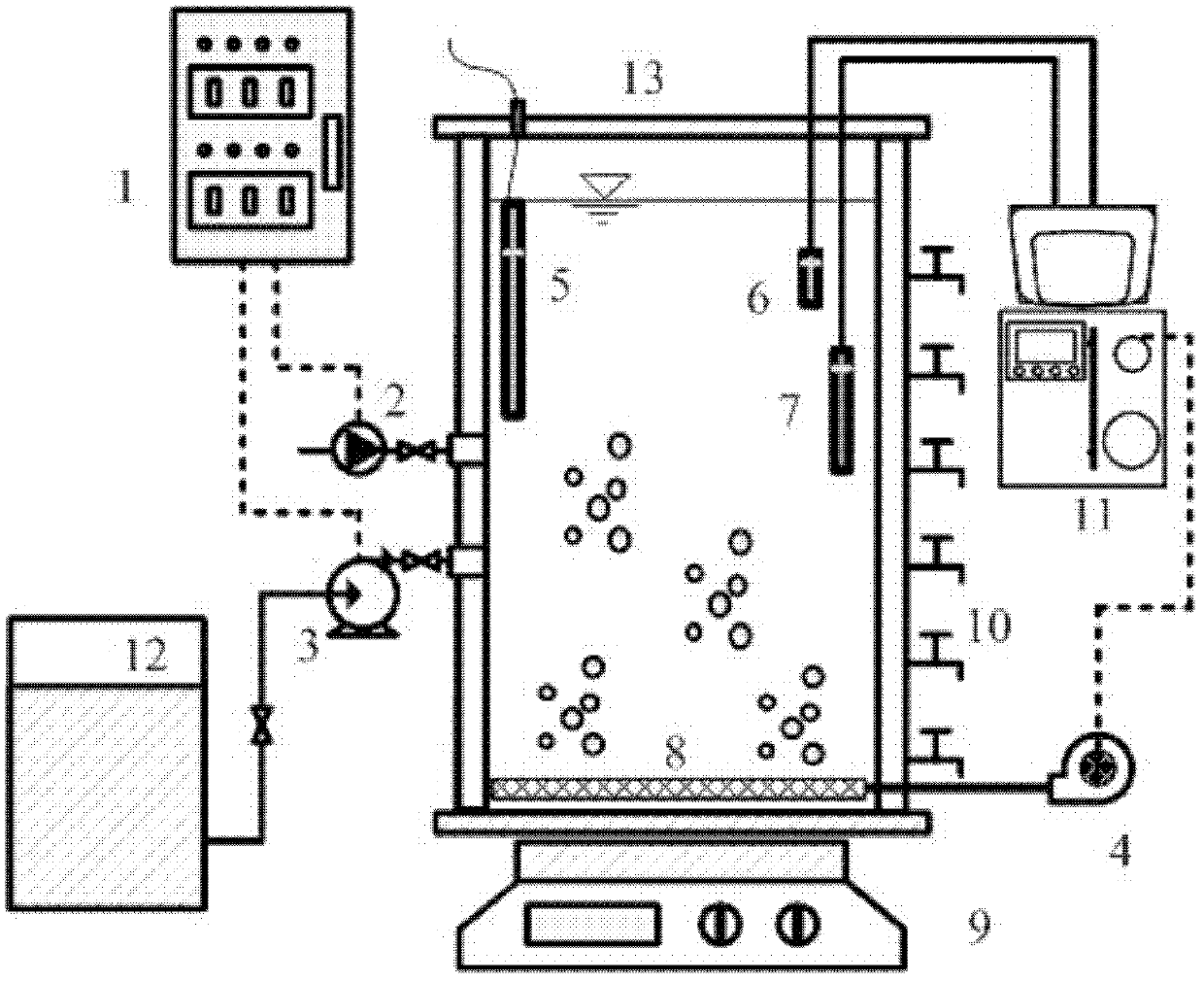

[0036] The volume of the reactor is 5L, and the raw water comes from domestic sewage in a living quarter.

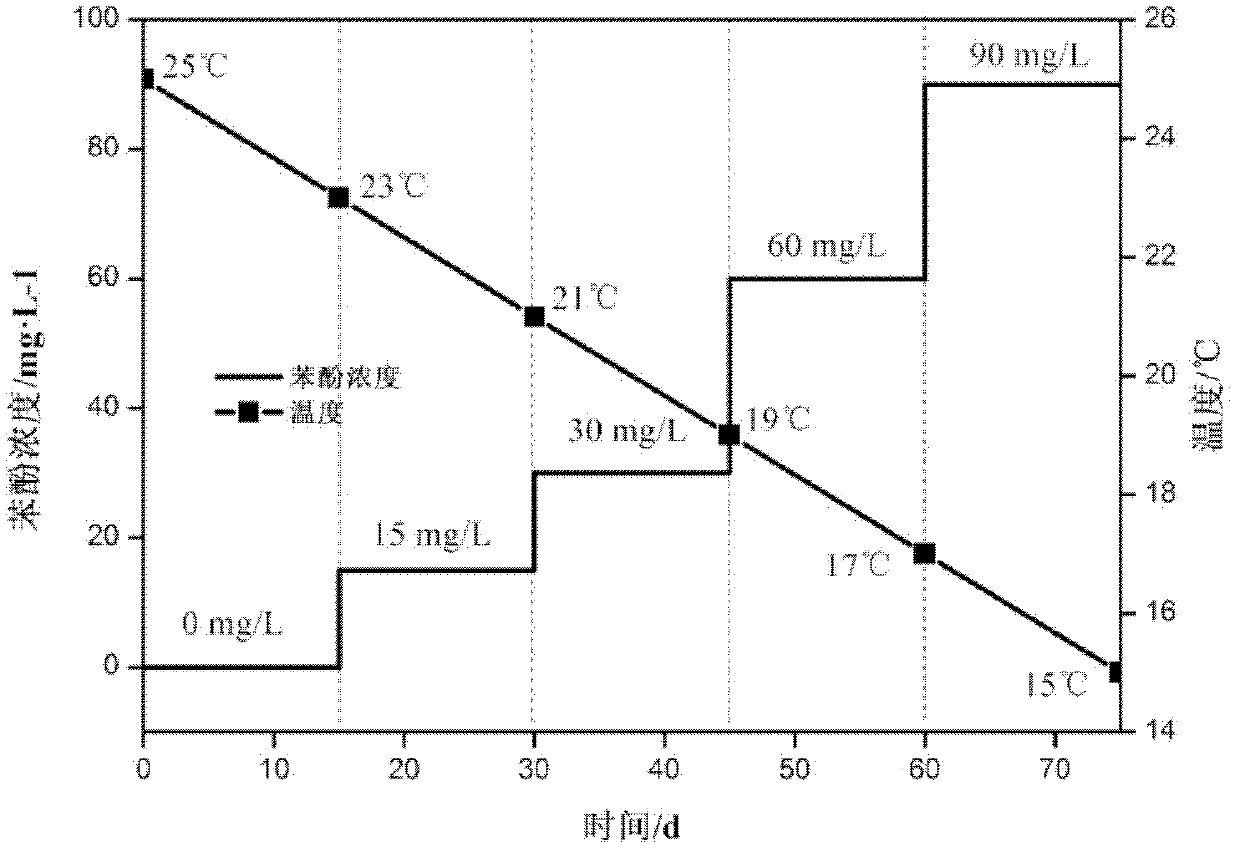

[0037] COD=190-270mg / L, NH 4 + -N=50~69mg / L, pH=7.20-7.80. The inoculum sludge was taken from the return sludge of the secondary settling tank of an urban sewage treatment plant in Beijing, which is a sludge with good nitrification performance throughout the process. At each stage, the sludge concentration in the sludge control system is maintained at the set level, and the DO is maintained at 0.5-1.3mg / L. During the implementation process, the temperature gradually decreases from 25°C to 15°C as the temperature decreases.

[0038] 1. The concentration of phenol is 0mg / L, 15mg / L, 30mg / L: the concentration of inoculated sludge is 3000mg / L, after 15 days of operation, the temperature gradually changes from 25°C to 19°C, and the effluent COD=32-54mg / L, NH 4 + -N2 - -N=2-4mg / L; NO 3 - -N=15-20mg / L; NO 2 - -N / NO 3 - The -N value is maintained between 9% and 22%, wi...

Embodiment example 2

[0043] The volume of the reactor is 10L, and the raw water comes from domestic sewage in a residential area.

[0044] COD=206~260mg / L,NH 4 + -N=51~70mg / L, pH=7.43-8.13. The inoculum sludge was taken from the secondary sedimentation sludge of a pilot reactor with good denitrification effect. At each stage, the sludge concentration in the sludge control system is maintained at the set level, DO is maintained at 0.5-1.3mg / L, and the temperature is gradually reduced from 25°C to 15°C during the implementation process.

[0045] 1. The concentration of phenol is 0-30mg / L: the concentration of inoculum sludge is 3000mg / L. After 15 days of operation, the temperature gradually changes from 25°C to 19°C, and the effluent COD=39-51mg / L, NH 4 + -N2 - -N=1-5mg / L; NO 3 - -N=17-23mg / L; NO 2 - -N / NO 3 - The -N value is between 5% and 15%, and the nitrous accumulation rate changes little.

[0046] 2. Phenol concentration 60mg / L: After 15 days of operation, the temperature gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com