Adhesive composition and optical member using the same

一种光学元件、组合物的技术,应用在非高分子粘合剂添加剂、粘合剂类型、黏合剂添加剂等方向,能够解决长老化时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5 and comparative example 1 and 2

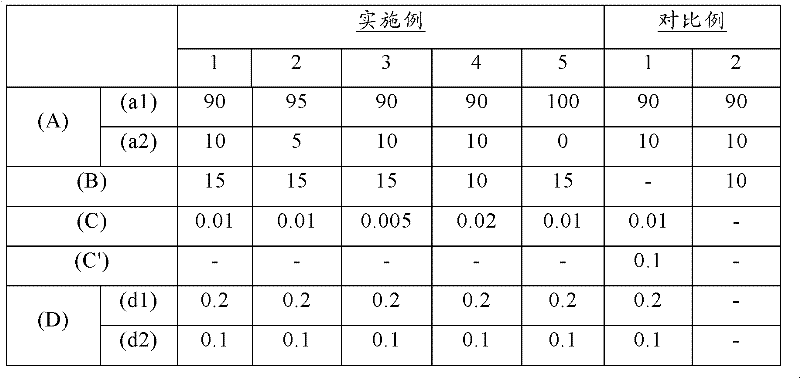

[0074] The components were mixed according to the composition listed in Table 1, ethyl acetate was added thereto to a concentration of 15%, and uniformly stirred for 20 minutes, thereby preparing a solution. The prepared solution was deposited on a PET release film (MRF38, thickness: 38 μm, Mitsubishi Polyester Film Inc.) to a dry thickness of 25 μm. Then, the solution deposited on the release film was dried in a drying oven at 120° C. for 3 minutes. The dried adhesive layer was deposited on the wide viewing angle coating of the polarizing plate coated with the wide viewing angle liquid crystal layer, and left in a constant temperature and humidity chamber (35° C., 45% RH) for 1 day.

[0075] Table 1

[0076]

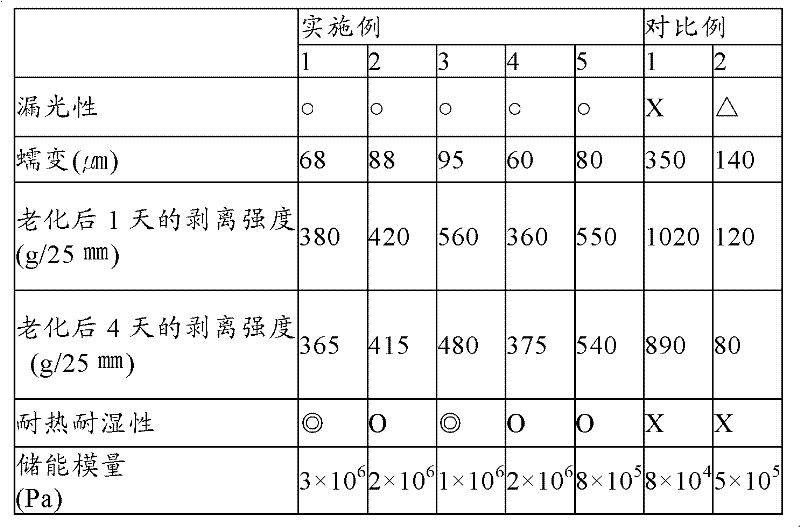

[0077] Evaluation of Physical Properties

[0078] (1) Light leakage resistance

[0079] After the release film was separated from each prepared adhesive sheet, the adhesive sheet was attached to an iodine polarizing plate having a thickness of 185 μm. The polariz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com