Adjustable coal mining machine rail

A shearer and adjustable technology, applied in the field of coal mine machinery and equipment, can solve the problems of resource waste, inappropriate size, waste, etc., and achieve the effect of solving supporting problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

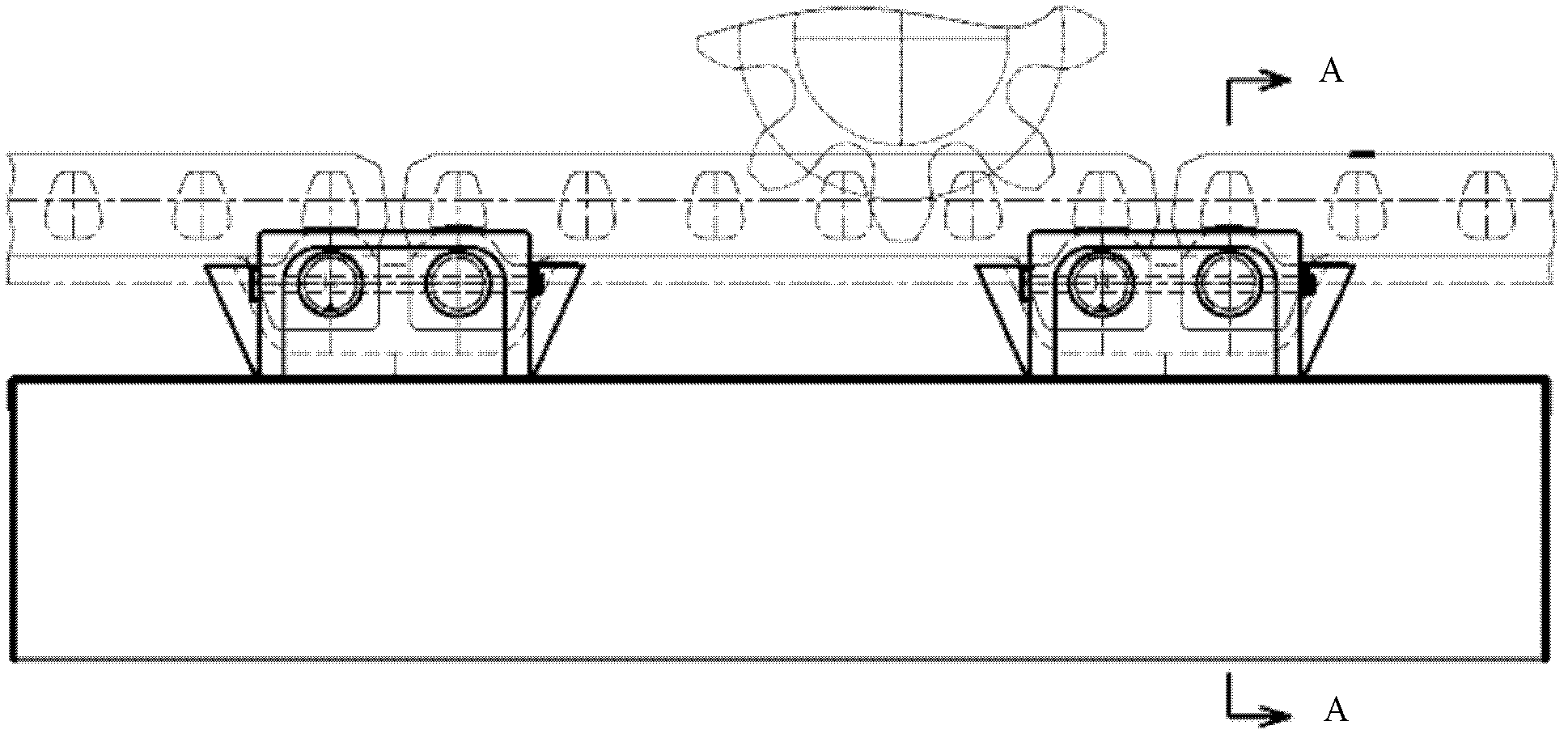

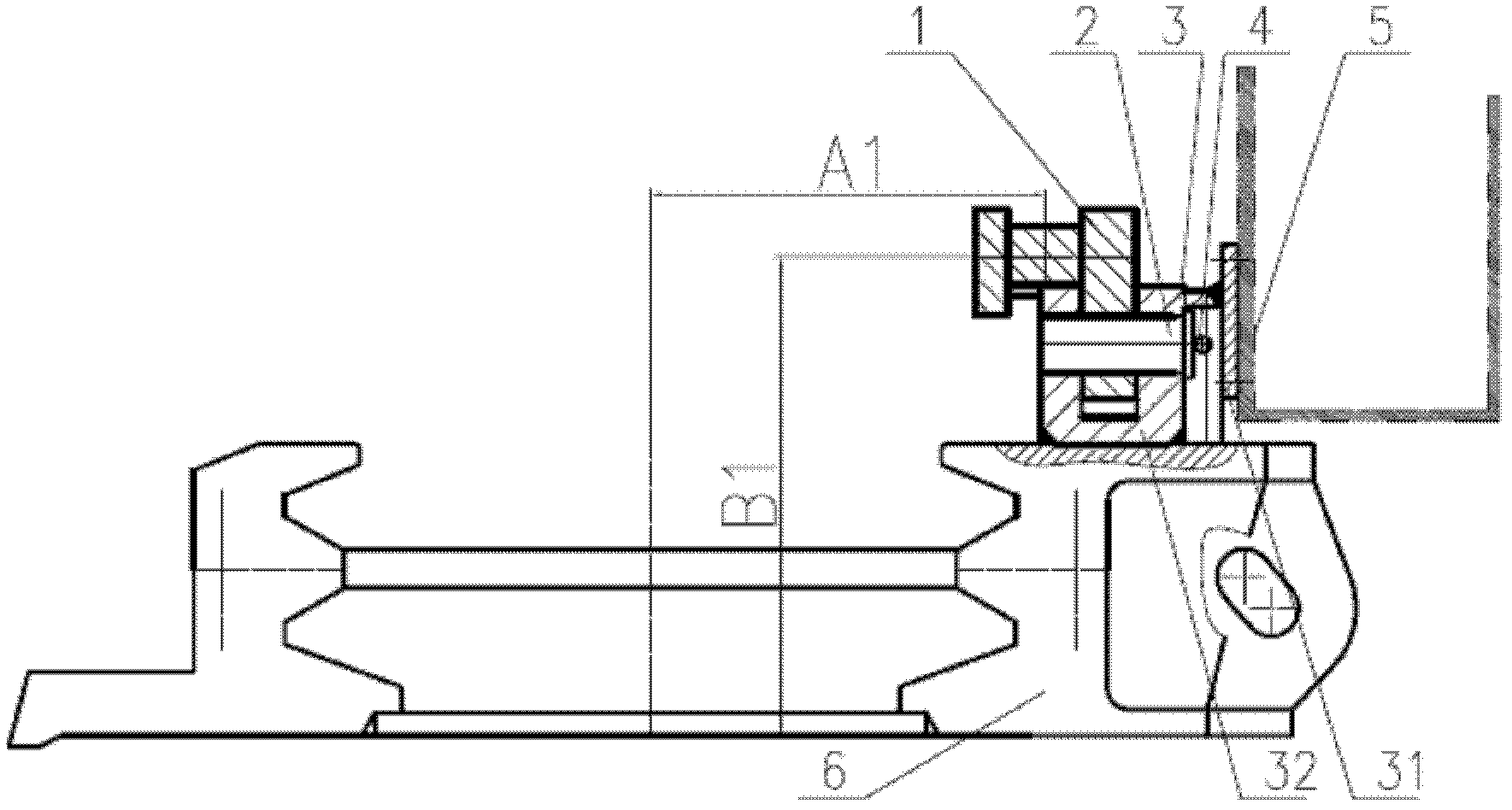

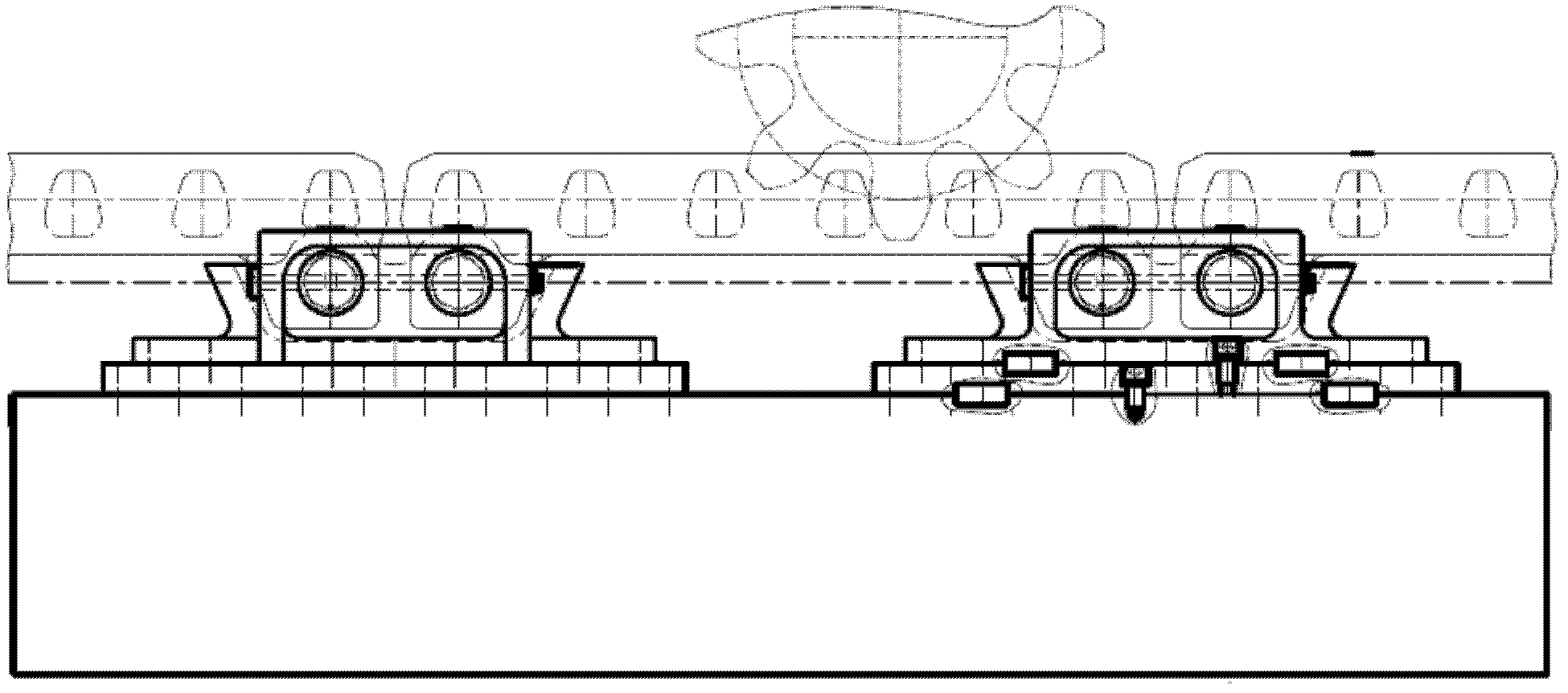

[0034] see Figure 3 to Figure 5 , the present invention discloses an adjustable shearer track, which includes: rack 1, rack fixing mechanism 2, movable rack seat 3', transition plate group 71, cable trough 5, conveyor Slot 6. In this embodiment, the rack fixing mechanism 2 is a pin. In order to prevent the pin from axially moving in series, the track of the shearer is also equipped with a stop pin 4 .

[0035] The movable rack seat 3' includes a connecting plate 31' and a movable seat 32', and the cable groove 5 is fixed on the connecting plate 31'; the rack 1 is fixed on the movable rack seat 3' through the rack fixing mechanism 2 .

[0036] The transition plate group includes one or more upper round pins 711, a transition plate 712, one or more lower round pins 713, and the upper side / lower side of the transition plate 712 is respectively provided with a plurality of upper round pins 711 / lower round pins. 713 corresponds to the hole. The movable rack seat 3' is fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com