Rapid testing device for pavement deflection

A road surface deflection and detection device technology, applied in roads, roads, road repairs, etc., can solve the problems of low test speed, slow test speed, waste of road resources, etc., to save time and human resources, improve effective utilization rate, Effect of Personal Safety Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

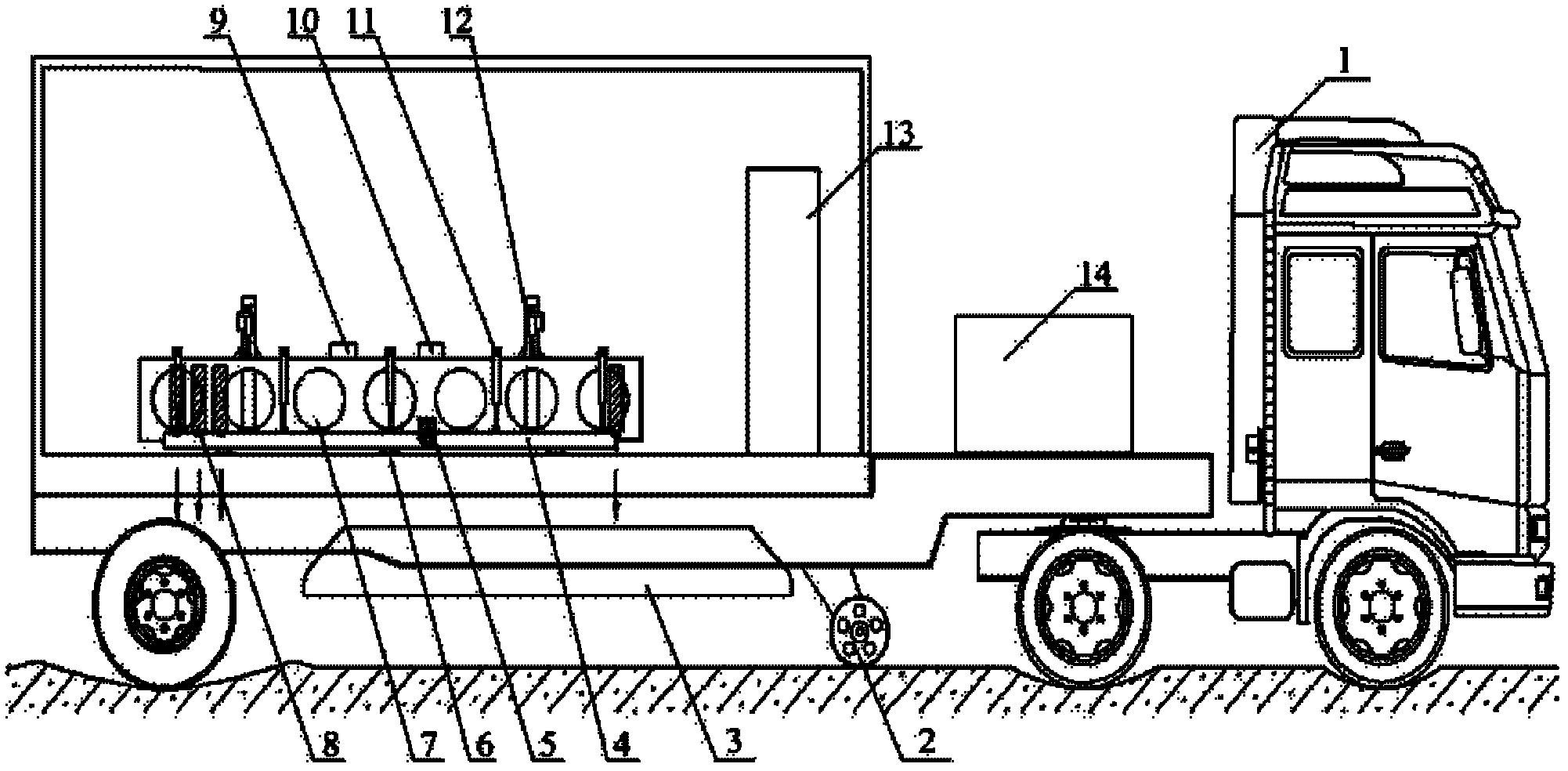

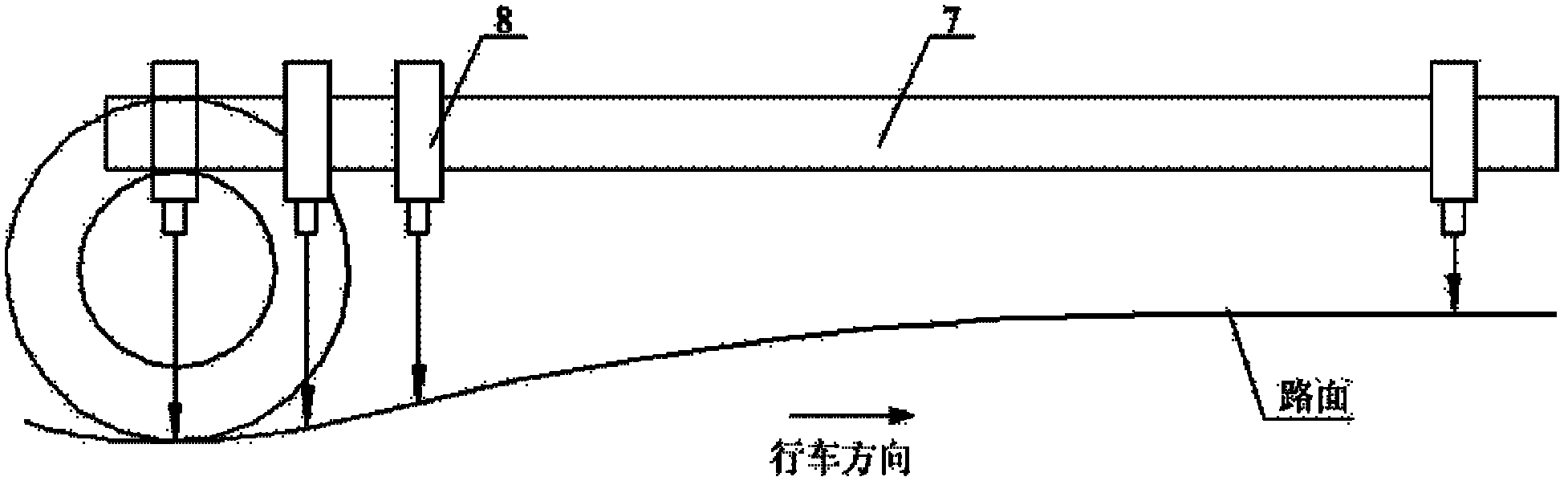

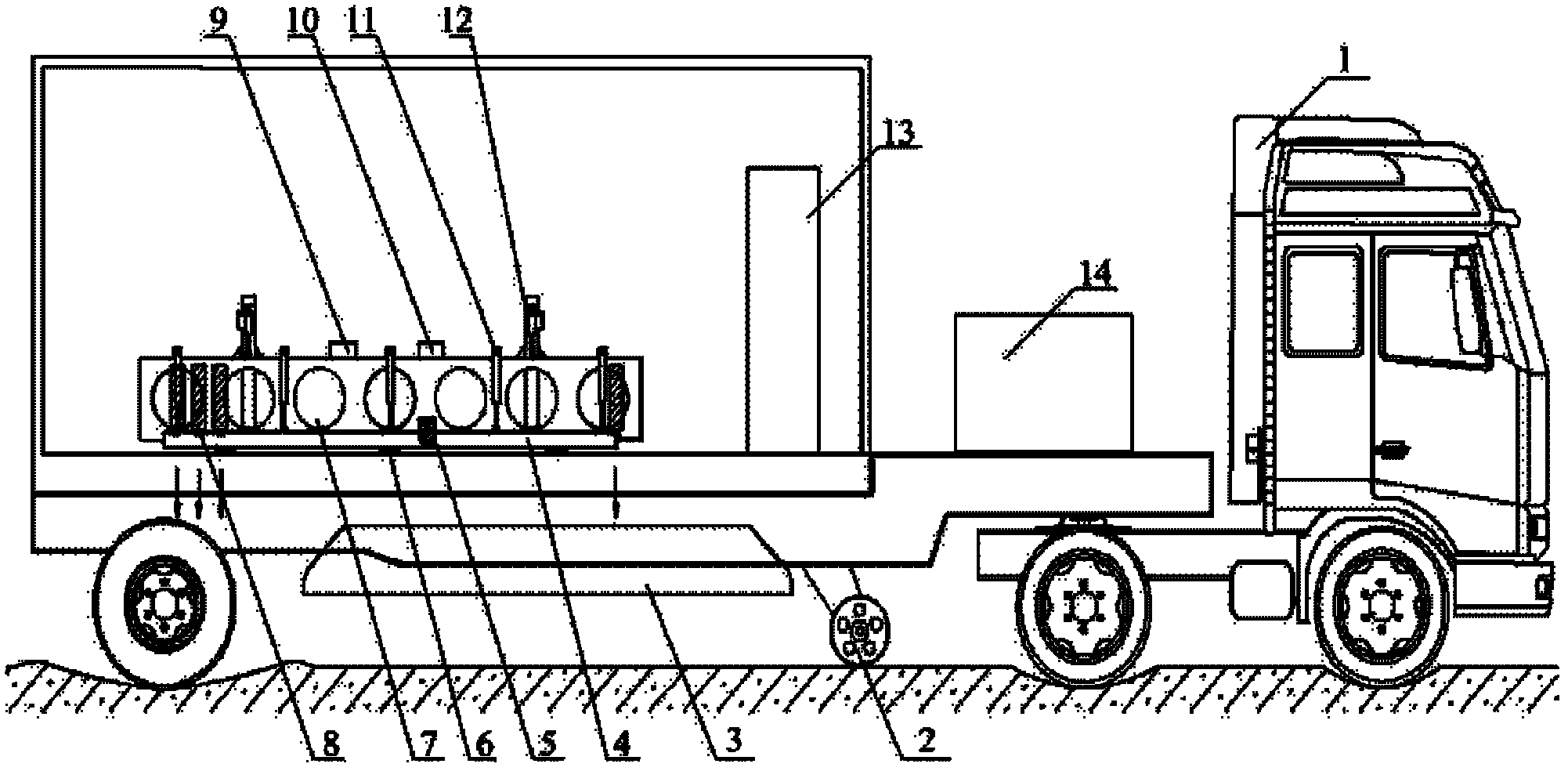

[0025] Such as Figure 1~2 In the shown embodiment, the rapid detection device for road surface deflection according to the present invention includes a rear towed test vehicle 1 and a shock absorption system, and a steel beam support 4 is arranged in the compartment of the test vehicle 1, and the steel beam support 4 is longitudinally arranged The test steel beam 7 is provided with several Doppler laser sensors 8 on the test steel beam 7. The shock absorption system includes a three-stage shock absorption system. The first stage shock absorption system is the test vehicle chassis shock absorption system, and the second stage shock absorption system is Real-time adjustment of the servo control system for testing the posture of the steel beam. The third-level shock absorption system includes a vibration isolation pad 6 arranged between the steel beam support 4 and the bottom of the carriage, and a damping cylinder 11 arranged on the steel beam support 4 to reduce vibration. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com