Friction-metallic yielding energy consumption combined control damping device applied to shear wall connecting beam and control method thereof

A shock absorption device and friction energy consumption technology, which is applied in the direction of anti-seismic and building components to achieve the effect of improving the anti-seismic effect, clear working principle and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

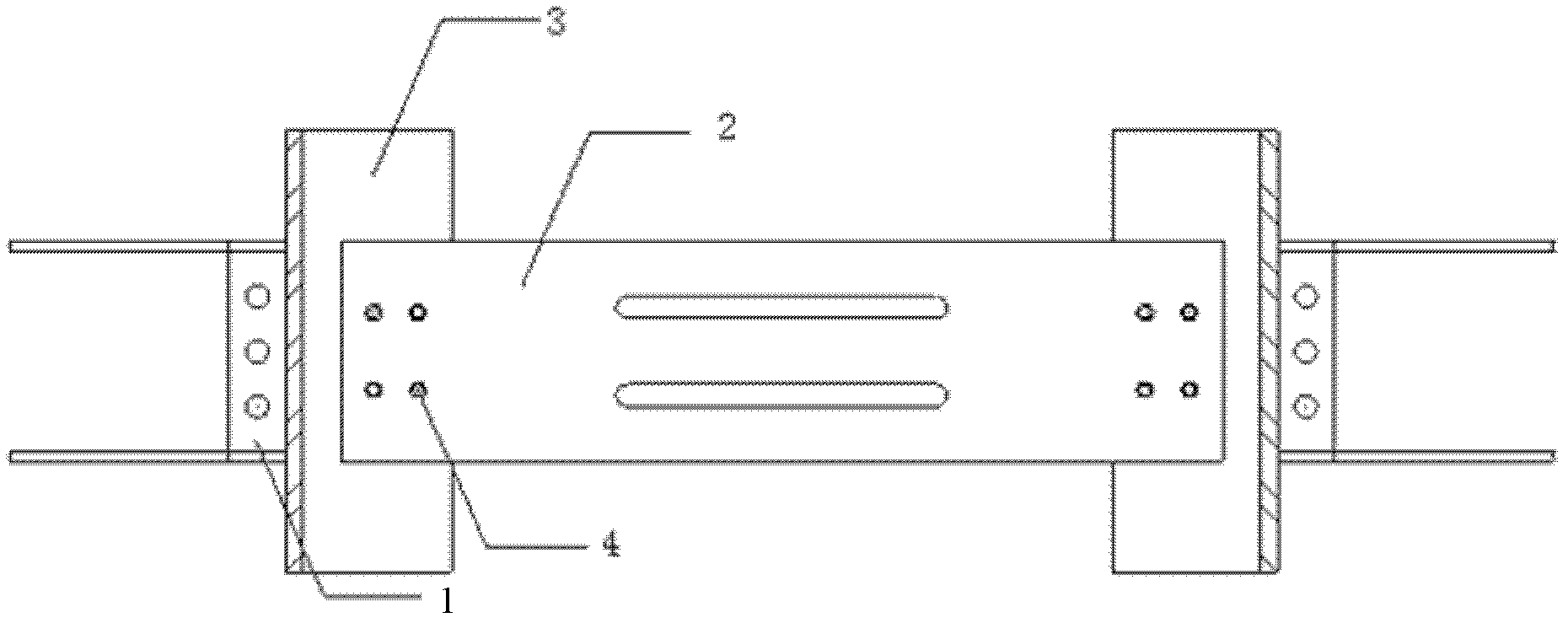

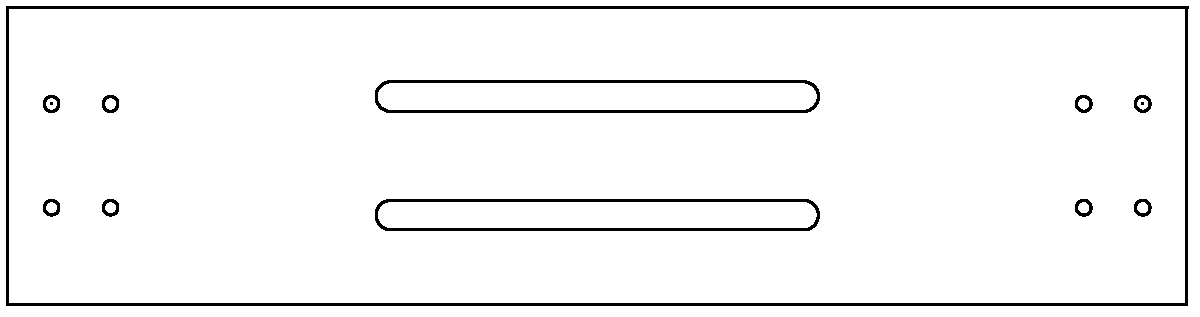

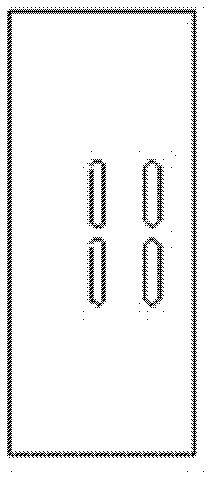

[0021] First, pre-cast the embedded area 1 and the shear wall together: weld the friction steel plate 3 and the embedded area 1 together; open bolt holes on the metal yield damper 2, and open holes for the bolts to slide on the friction steel plate 3 Groove; the metal yield damper 2 and the friction steel plate 3 are connected together by bolts, and the metal yield damper and the friction steel plate are connected in series to form a whole as a shock absorbing device.

Embodiment 2

[0023] Under the action of small earthquakes, the main structure is in an elastic working state, and the joint control device works well without damage. Among them, the friction working area of the joint control device does not enter the slipping stage, and the mild steel damper is in the elastic deformation stage. Under moderate earthquakes, the main structure is in an elastic working state, and the joint-control damper slips in the frictional working area to dissipate structural energy, and the mild steel damper is still in the elastic deformation stage. After the earthquake, carry out necessary overhaul and reset on the device, and it can continue to be used after maintenance. Under the action of a large earthquake, some components in the main structure enter the elastic-plastic stage, resulting in limited damage, but the structural integrity is still intact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com