Point hanging porcelain plate for point hanging construction

A porcelain plate and spot hanging technology, which is applied in the direction of covering/lining, construction, building structure, etc., can solve the problems of reducing construction costs, wasting labor, and hollowing of porcelain plates, so as to reduce construction costs and avoid hollowing of porcelain plates , Reduce labor and time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

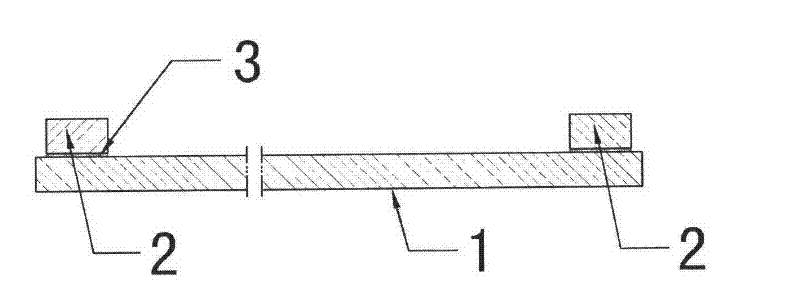

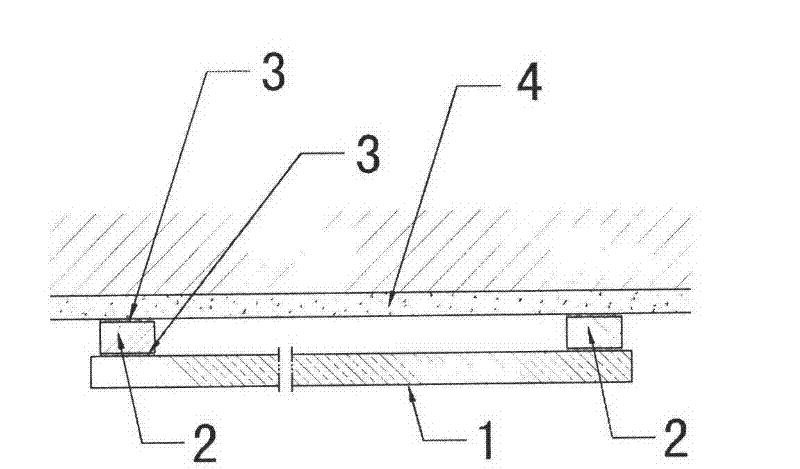

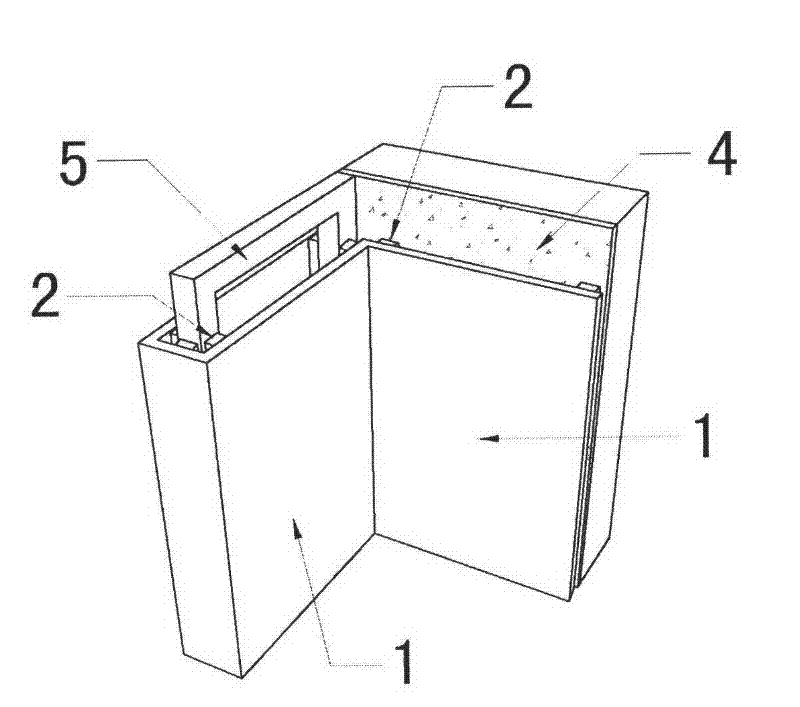

[0014] Example: such as figure 1 As shown, a spot-hanging porcelain plate for spot-hanging construction includes a porcelain plate 1, and the back of the porcelain plate 1 is bonded and fixed with a porcelain plate back bar 2 through epoxy resin AB glue 3.

[0015] refer to figure 1 , figure 2 , image 3 , the present embodiment carries out the scheme of spot hanging construction:

[0016] 1. According to the final plan, accurately release the paint layer 4 to complete the upper line, the position of the ground hole, and make the ash cake.

[0017] 2. Strictly follow the completion of surface lines and ash cakes for cement mortar painting. Before painting, the interface agent must be approved once; the mix ratio of cement mortar must be controlled to prevent the strength of the painting layer from being too small due to too little cement; it must be well controlled The quality of the painting, flatness, verticality and squareness must meet the requirements, and the painti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com