Pressure regulating valve of water turbine volute casing

A pressure regulating valve and water turbine technology, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve the problems of multiple capital investment, long R&D cycle, etc., and achieve the effect of simple overall structure, large flow capacity, sensitive and stable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

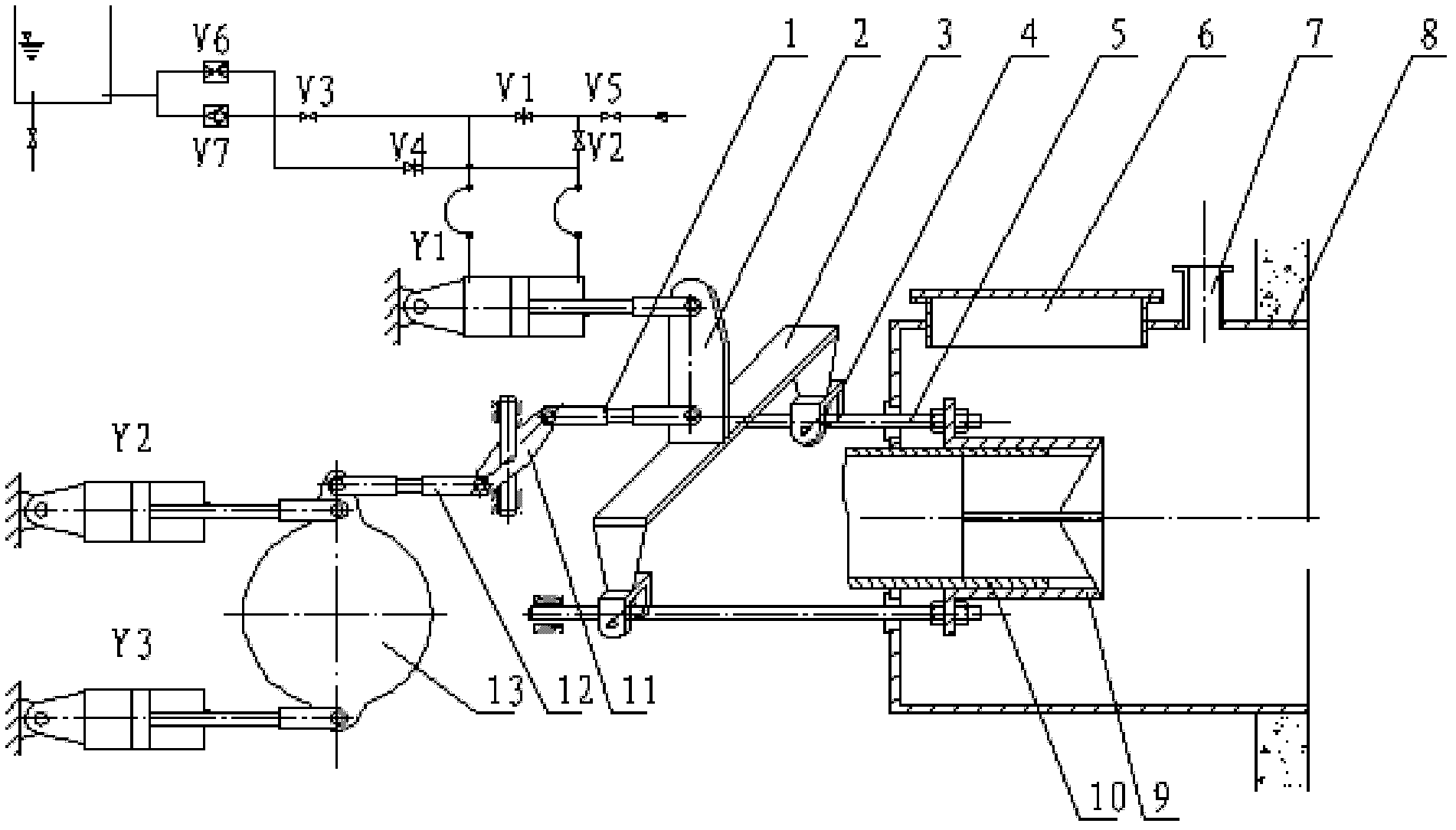

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0017] A hydraulic turbine volute pressure regulating valve, installed at the water inlet of the hydraulic turbine volute, the central pipe 10 of the pressure regulating valve communicates with the volute (not shown in the figure), and the tail end of the central pipe is installed on the pressure regulating valve In the discharge channel 8.

[0018] A process installation hole 6 is formed on the discharge flow channel, which is used to install or repair the pressure regulating valve components in the outlet pool; a vent hole 7 is also formed on the discharge flow channel, so that the air can directly enter the discharge flow of the pressure regulating valve evenly inside the road.

[0019] A valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com