Internally tangent barrel-shaped four-rotor displacement pump

A four-rotor, positive displacement pump technology, applied in the field of positive displacement pumps, can solve the problems of small flow rate of conveying medium and limited working range, and achieve the effects of increasing contact area, low vibration and noise, and high rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

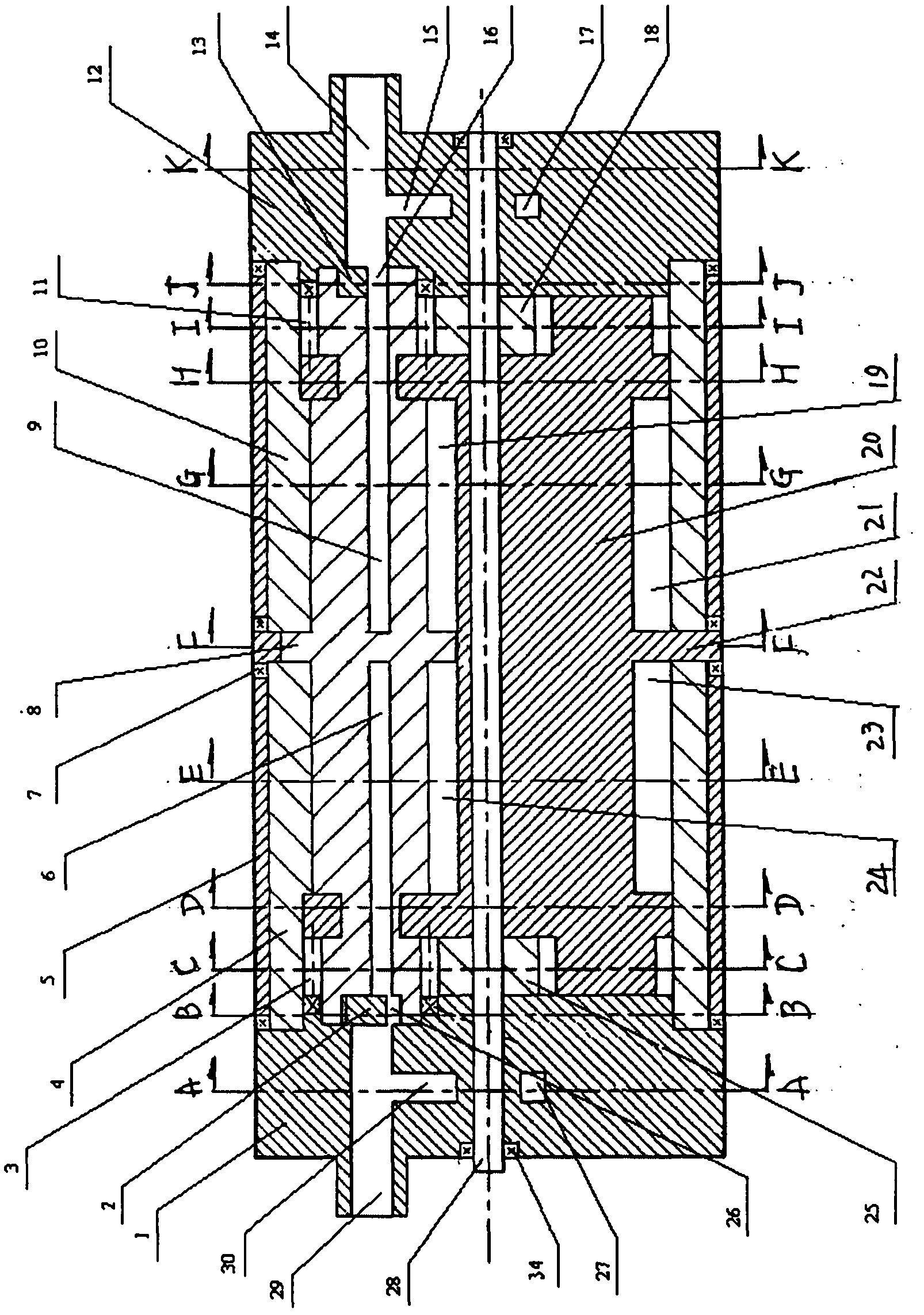

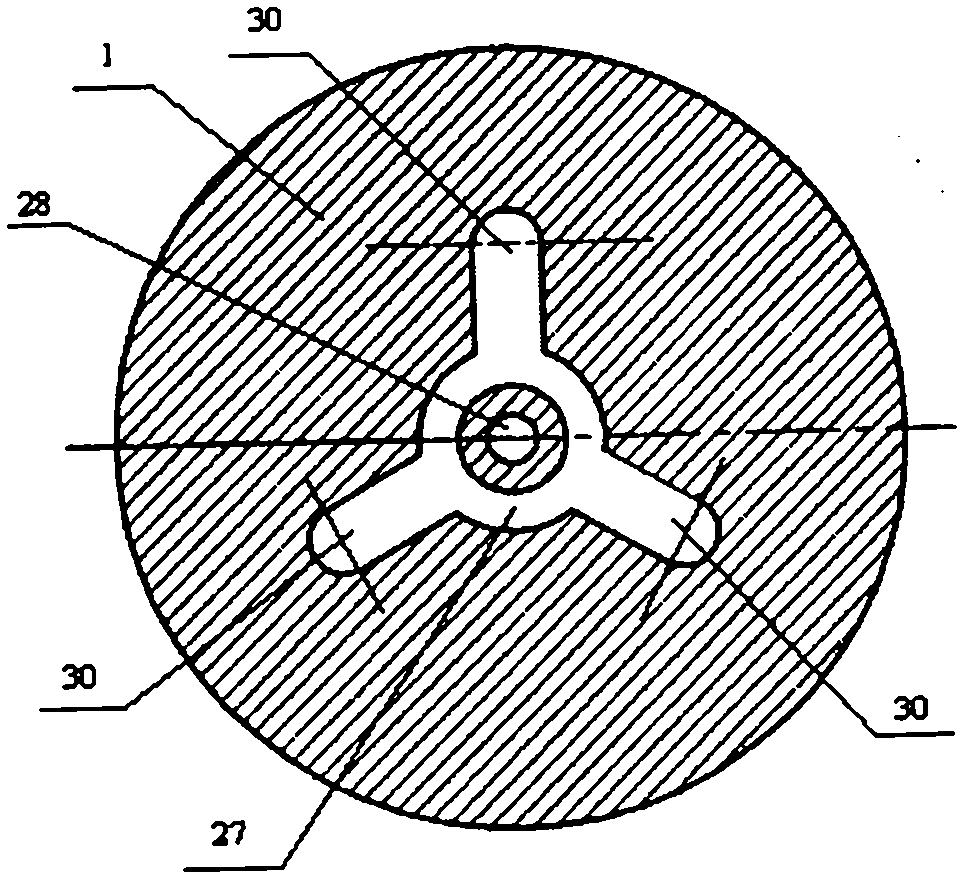

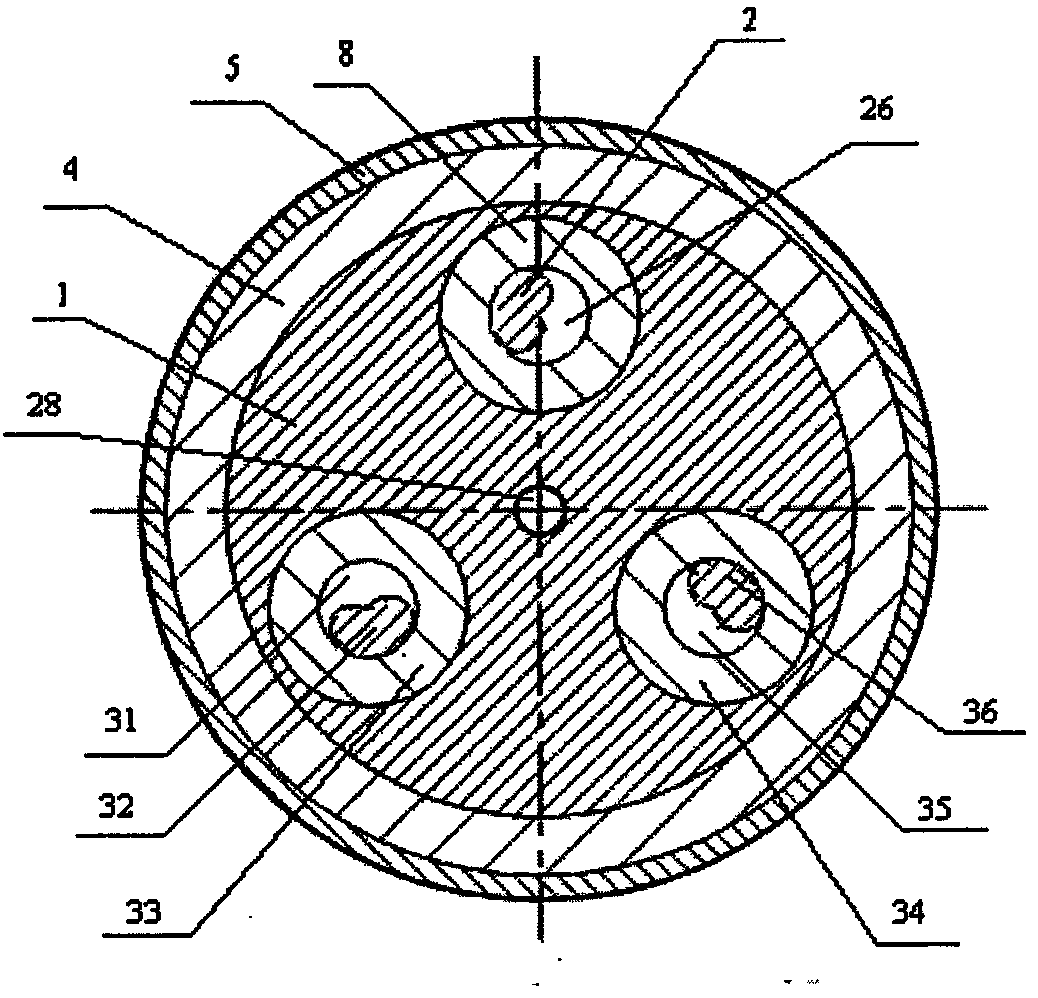

[0030] Figure 1 to Figure 12In the pump casing 5, there is an outer rotor connected to the inscribed bearing. The stator 20 inside the outer rotor has a stator partition 22, which divides the outer rotor into two parts: the left outer rotor 4 and the right outer rotor 10. , the left outer rotor 4 and the annular cavity formed between the stator 20 and the stator diaphragm 22 constitute the left outer rotor working chamber 23, while the right outer rotor 10 and the annular chamber formed between the stator 20 and the stator diaphragm 22 constitute the right The outer rotor working cavity 21 is provided with an inner gear on the inner cavity wall of the left outer rotor 4 and is evenly distributed with the first ridge 42 of the left outer rotor, the second ridge 48 of the left outer rotor and the third ridge 53 of the left outer rotor , the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com