Diving-pump water-lubricated anti-thrust device

A water-lubricated, submersible pump technology, applied to parts, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as increased serial momentum, shortened service life, and wear of pump blades to reduce friction damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

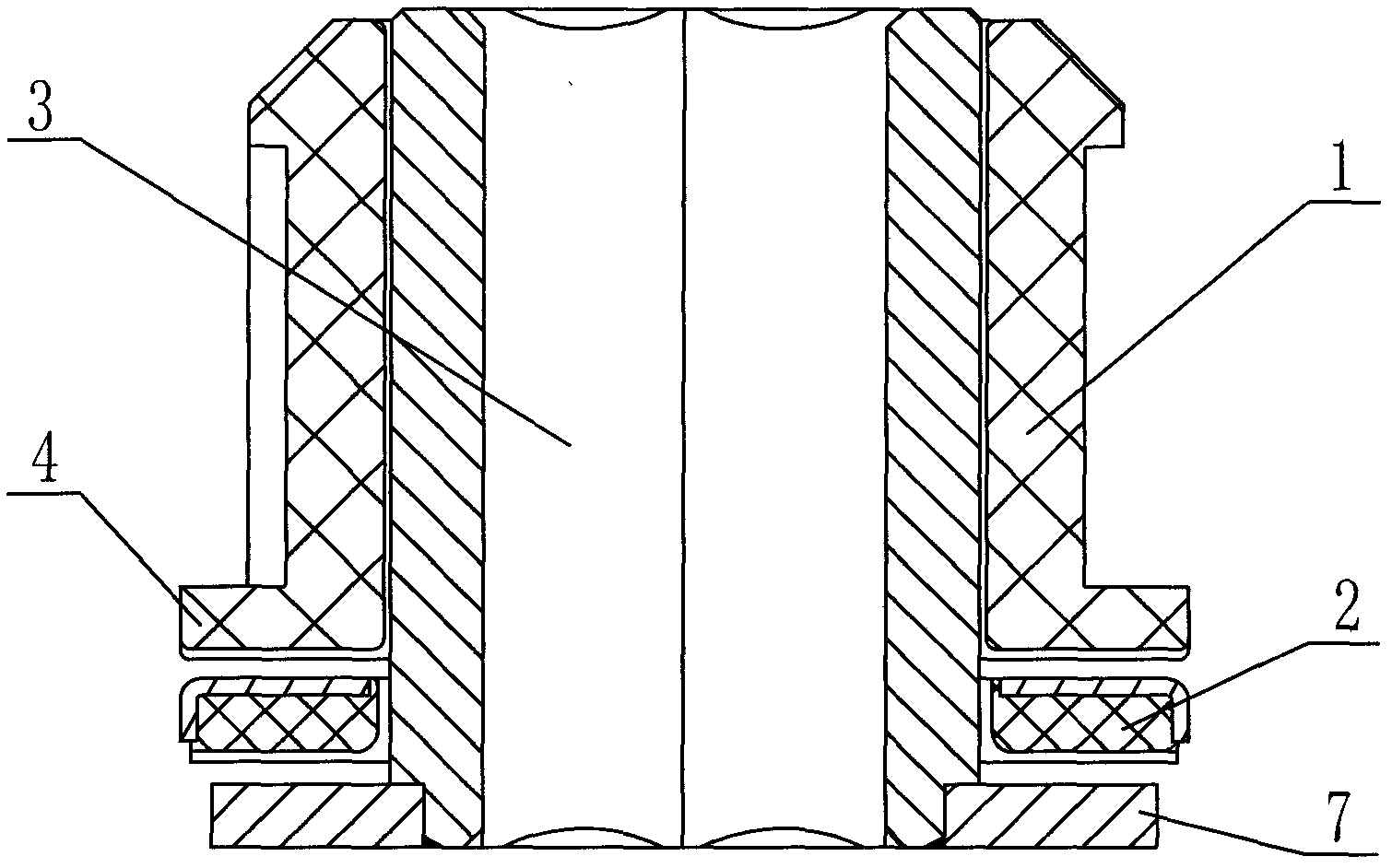

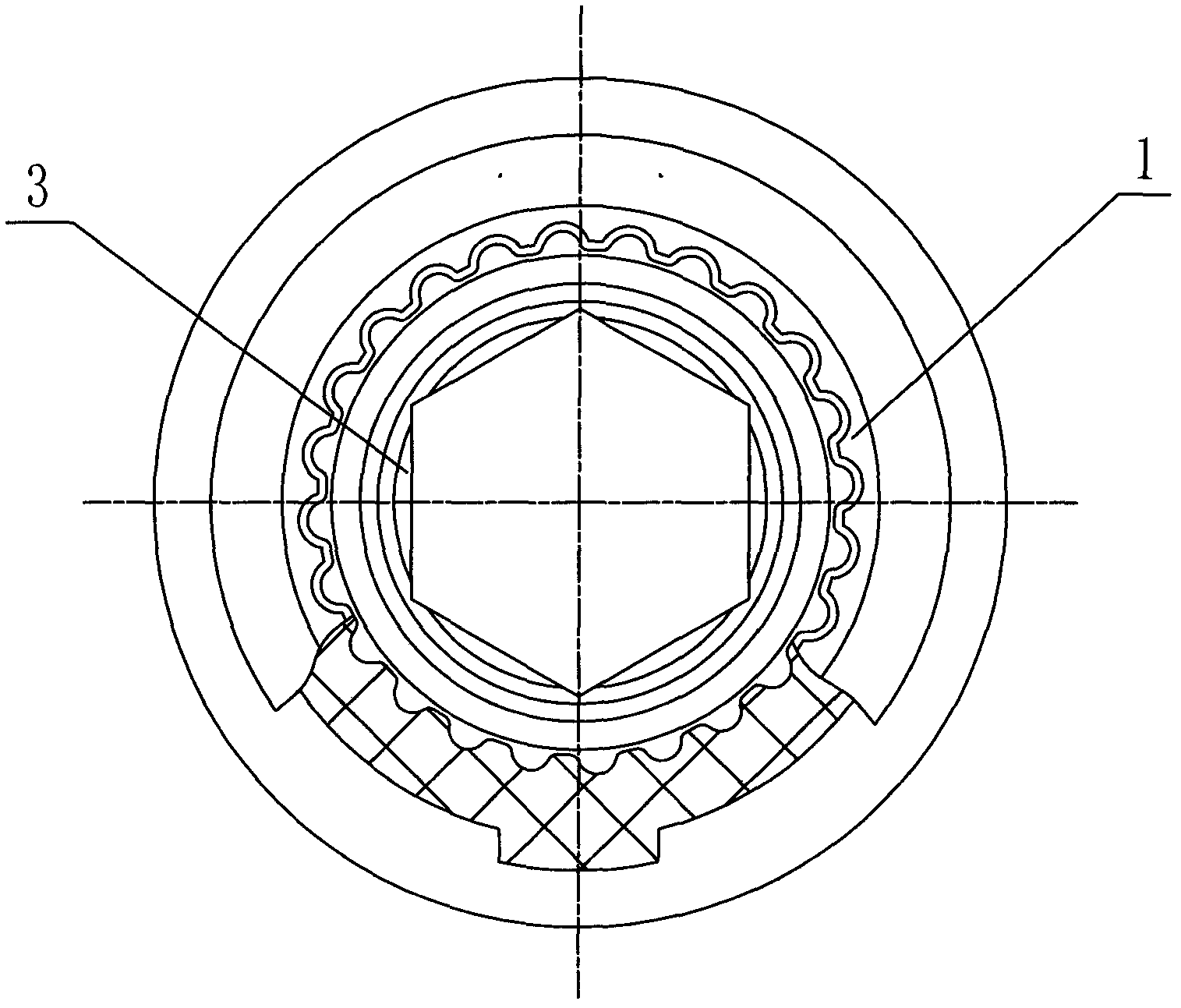

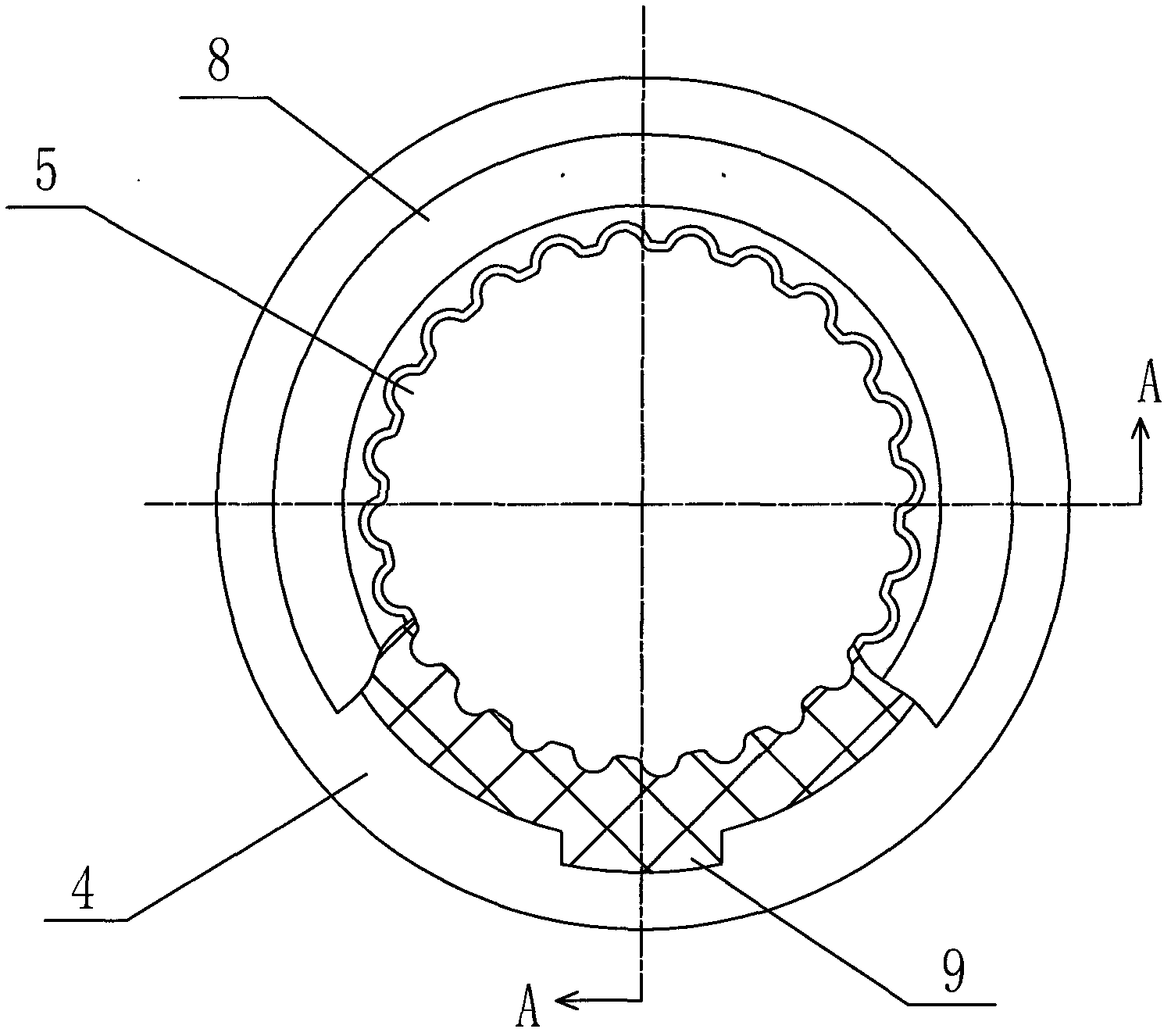

[0021] Depend on Figure 1-11 As shown, the embodiment of the submersible pump water lubrication thrust device of the present invention is: comprising a bearing sleeve 1, a thrust bearing disc 2 and an axle sleeve 3, the bearing sleeve 1 is a cylinder with a thrust flange flange 4 at one end, The flange end face of the thrust flange flange 4 has radially radial and uniformly distributed water guide grooves 5, and the water guide grooves 5 also extend to the entire inner hole wall of the bearing sleeve 1. The thrust bearing disc 2 has a central hole The flat disc has radially radial and evenly distributed combing grooves 6 on one end surface, the combing grooves 6 extend to the entire inner wall of the central hole, and the other end surface is smooth, and the shaft sleeve 3 has a thrust flange at one end The cylindrical body of the flange 7 is slidably fitted with the pump shaft 14 through the inner hole and can rotate with it, and the thrust bearing disc 2 and the bearing sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com