Positioning connection pin

A technology for connecting pins and king pins, which is applied to connecting components, threaded fasteners, screws, etc., can solve the problems of difficult alignment of pin holes, time-consuming assembly, poor operability, etc., and achieves low drilling accuracy requirements. , good safety, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

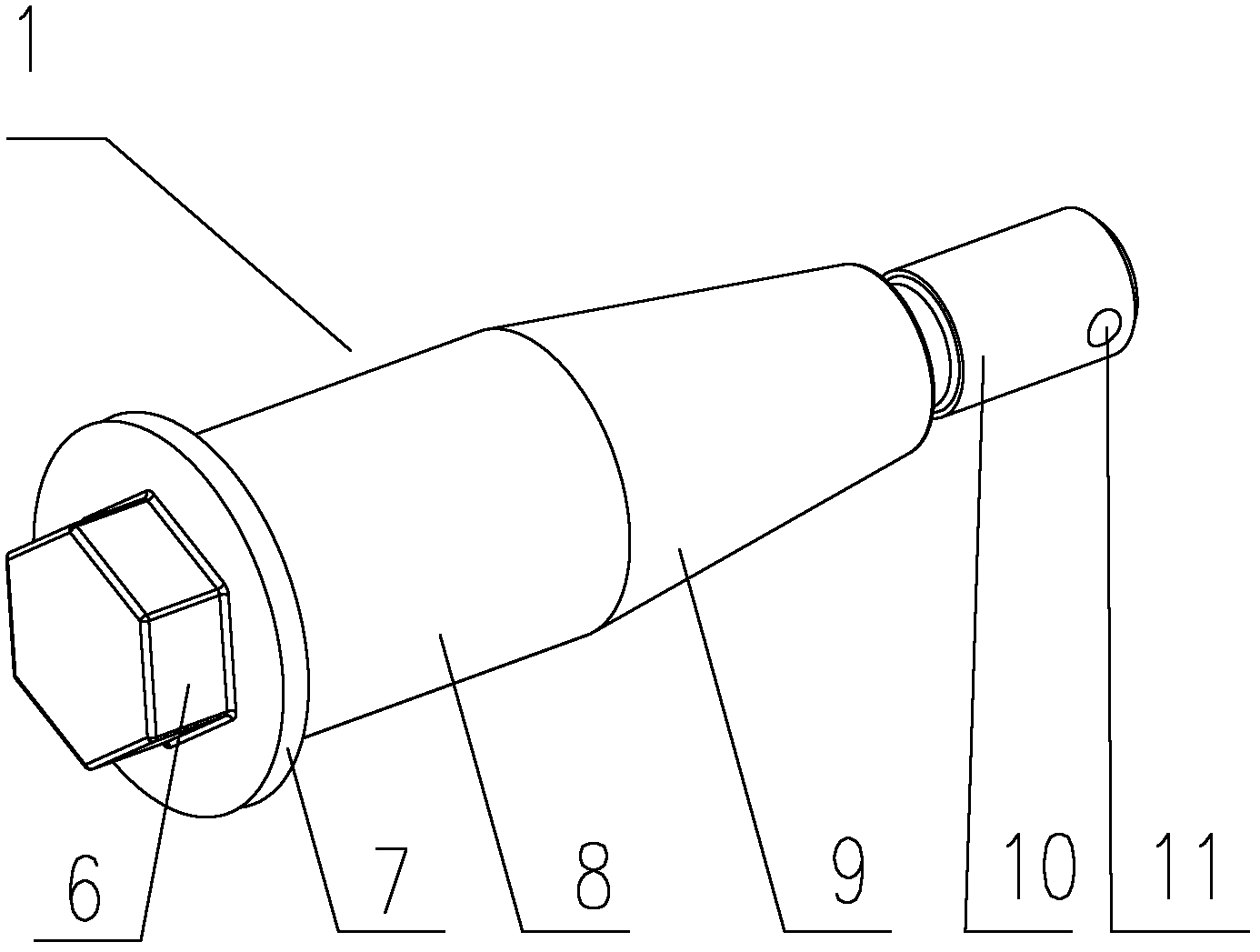

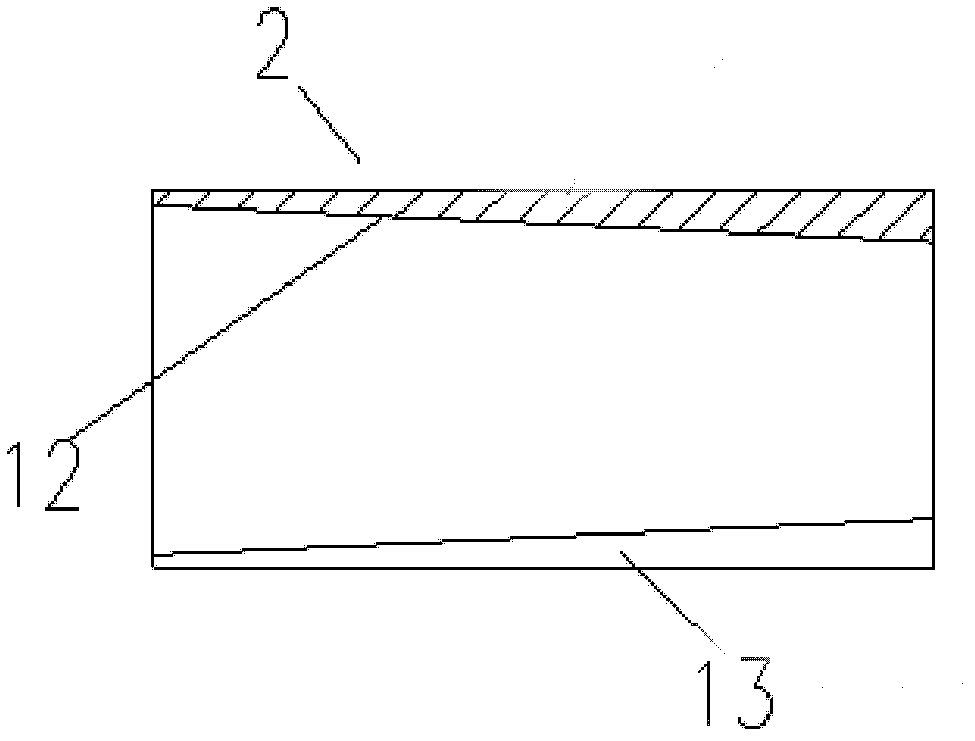

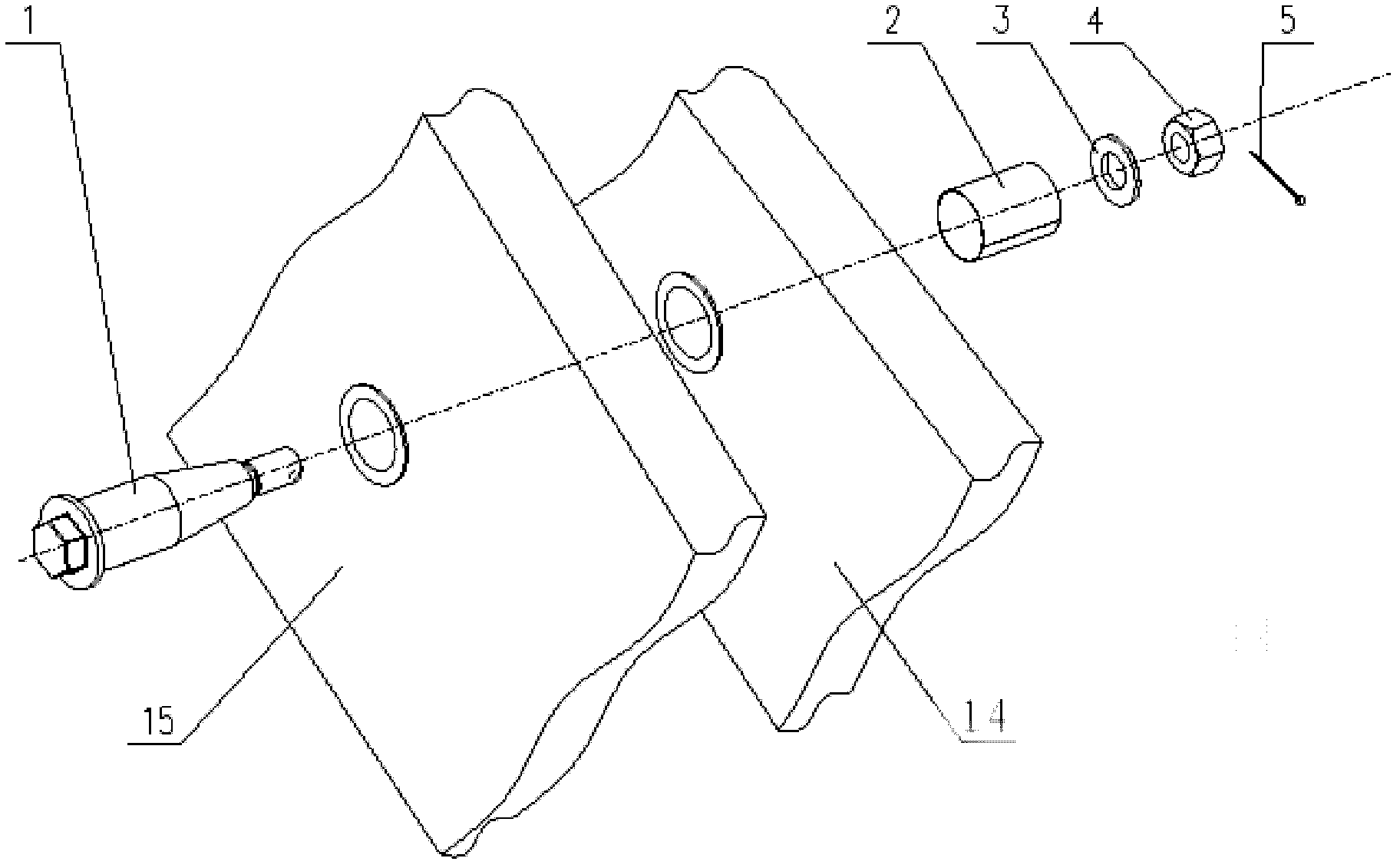

[0015] see figure 1 , figure 2 and image 3 According to this, the kingpin shaft 1 is provided with a flange 7, a cylindrical shaft section 8, a conical shaft section 9, and a threaded section 10. The end of the flange 7 away from the cylindrical shaft section 8 is provided with a hexagonal head 6 for easy clamping of loading and unloading tools. The threaded section 10 is provided with a pin hole 11 and a cotter pin 5, and also includes a cylindrical pin sleeve 2. The cylindrical pin sleeve 2 has a conical inner hole and is provided with a radial opening groove 13. The conical inner hole of the cylindrical pin sleeve 2 12 fits and fits on the conical shaft section 9 of the main pin shaft 1, the washer 3 and the nut 4 are installed on the threaded section 10 and the cotter pin 5 cooperates with the pin hole 11 to lock.

[0016] The hexagona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com