Differential mechanism with anti-wearing differential shell

A differential gear and differential housing technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of differential damage, gear grinding, differential noise increase, etc. Achieve the effect of simple and convenient maintenance, low cost and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

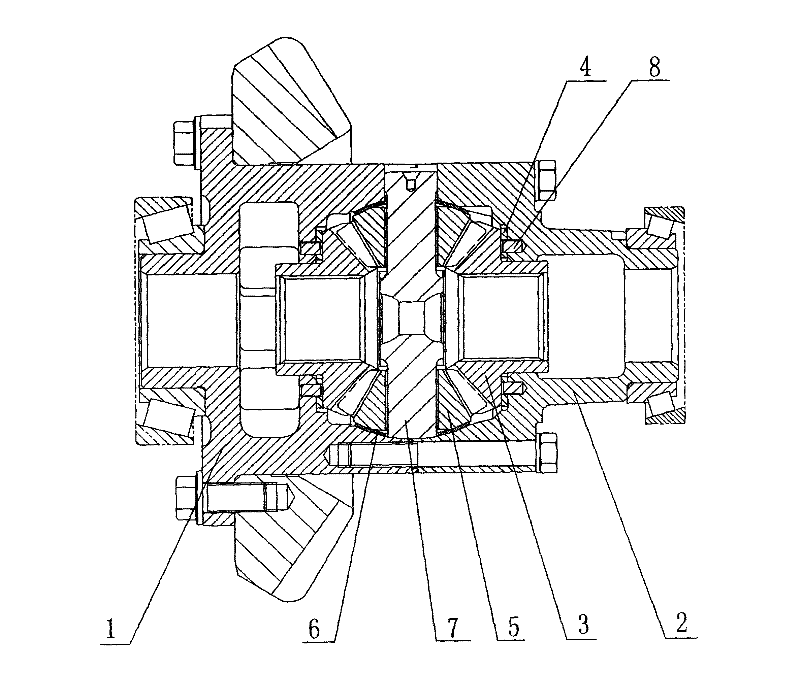

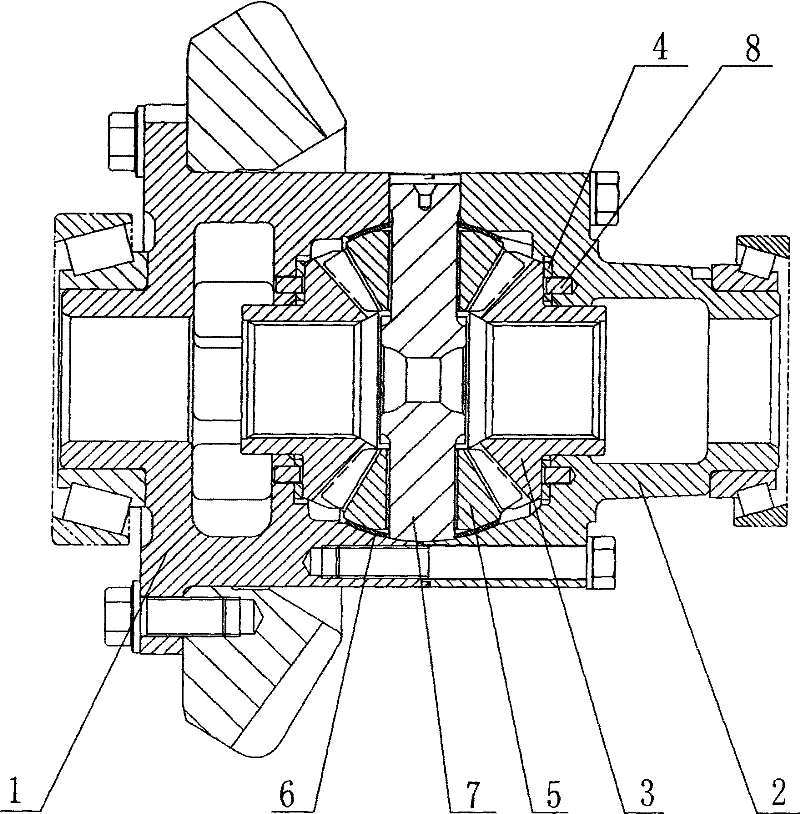

[0009] Such as figure 1 As shown, a differential case wear-resistant differential consists of a left differential case 1, a right differential case 2, a side gear 3, a side gear spacer 4, a planetary gear 5, a planetary gear spacer 6 and The cross shaft 7 is composed; the side gear gasket 4 is respectively fixed on the inner walls of the left differential case 1 and the right differential case 2 through positioning pins 8 . The dimension from the outer end of the positioning pin to the outer surface of the side gear gasket is greater than 2MM.

[0010] The detailed implementation process is to drill three holes on the side gear spacer 4, and process three holes with the same index on the left and right differential cases at the same time, and use three positioning pins 8 that have been calculated in detail to place the three holes. It locks, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com