Multi-channel underwater feeding device

A sampling device, multi-channel technology, applied in the direction of electromechanical device, casing/cover/support, engine sealing, etc., can solve the problems of complex sealing structure, limited use depth, low reliability, etc., and achieve oil pressure compensation Durable and reliable performance, improved sealing performance and pressure resistance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

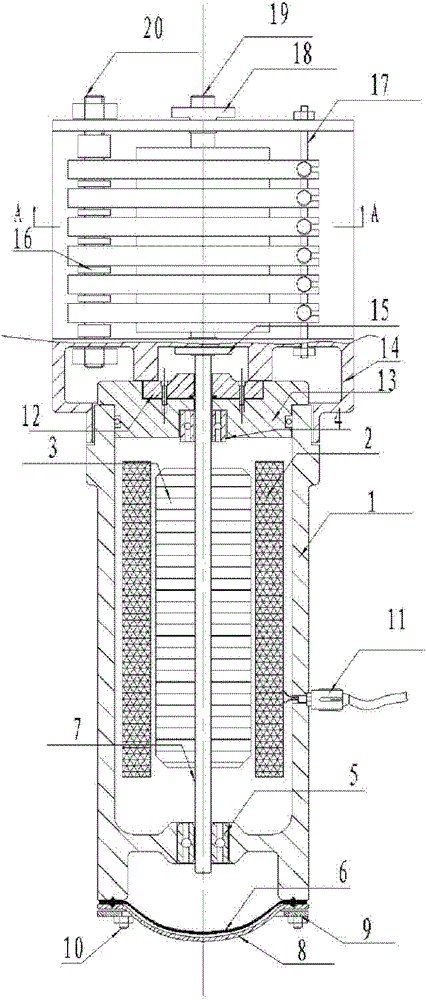

[0046] Such as figure 1 as shown, figure 1 It is a front view of the main structure of the multi-channel underwater sampling device of the present invention. The utility model relates to a multi-channel underwater sampling device, which comprises a rotary cylinder base part and a motor part, and the rotary cylinder base part and the motor part are connected by keys.

[0047] Drum base part includes drum base 14, PTFE rear axle seat 15, PTFE front axle seat 18, locking shaft 17, washer 16, shaft sleeve 19, rotating shaft 20, hose 22, spring Lock 23, hose lock 24 and drum 21;

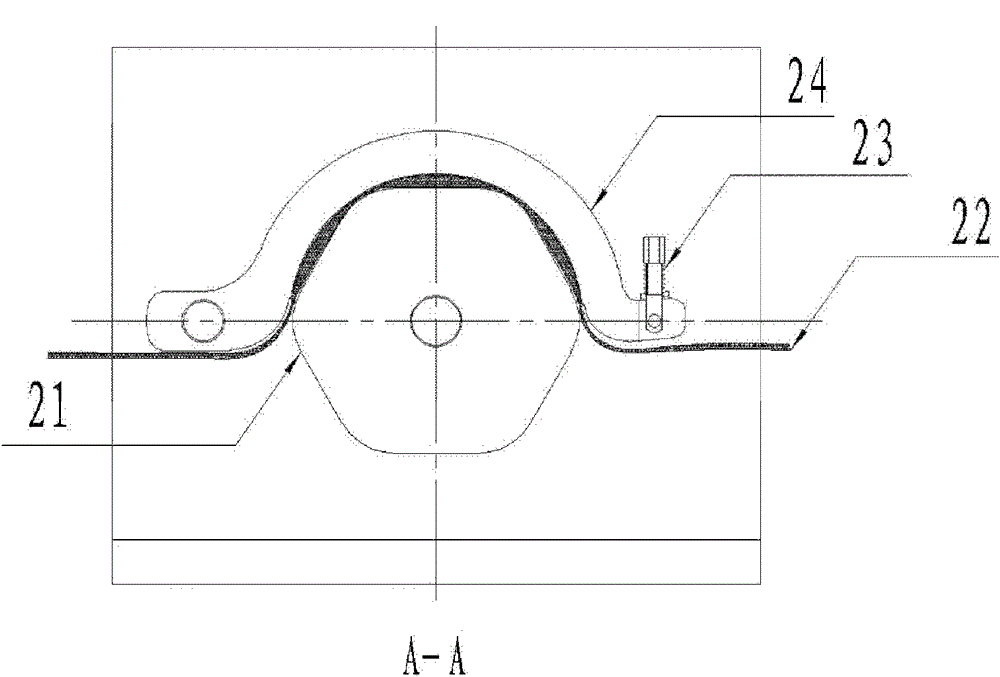

[0048] Such as figure 2 as shown, figure 2 It is an A-A view of the main structure front view of the multi-channel underwater sampling device of the present invention. Drum 21 is positioned in drum base 14, and the central round hole of one end of drum base 14 connects polytetrafluoroethylene front axle seat 18, and the central round hole of the other end connects polytetrafluoroethylene rear axle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com