Two-way electromagnetic vale with diaphragm structure

A technology of connecting solenoid valve and diaphragm structure, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as screw loosening and isolation diaphragm leakage, and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

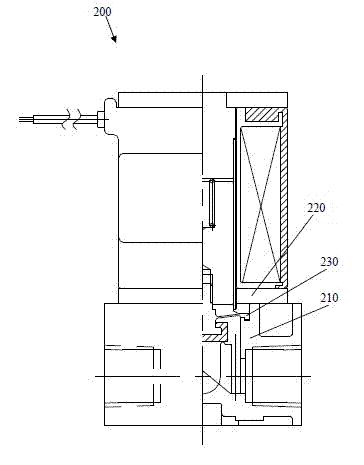

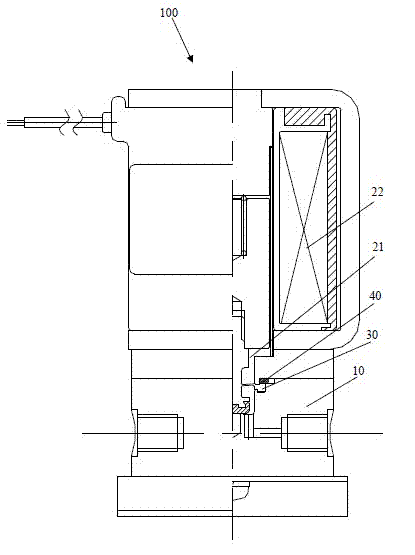

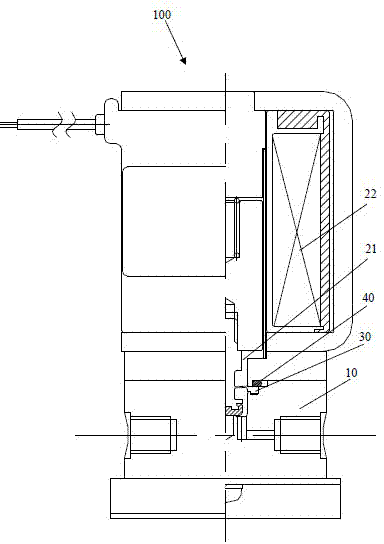

[0017] Such as figure 2 As shown, the diaphragm structure two-way solenoid valve 100 of the present invention includes a valve body 10, an electromagnetic drive part 21 installed on the valve body 10, an electromagnetic coil 22 installed on the electromagnetic drive part 21, and an electromagnetic coil 22 installed on the valve body 10 and the solenoid valve. The diaphragm 30 is separated between the driving parts 21 , and a sealing ring 40 is arranged between the electromagnetic driving part 21 and the valve body 10 . In the present invention, the electromagnetic driving part 21 and the valve body 10 are assembled and fixed by screws. Furthermore, the sealing ring 40 is disposed between the electromagnetic driving part 21 and the isolation diaphragm 30 . The sealing ring 40 is an O-ring. The part of the valve body 10 in contact with the liquid is made of anti-corrosion material. The anti-corrosion material is an anti-corrosion resin material.

[0018] When the liquid flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com