Novel pipe joint

A new type of pipe joint technology, applied in the direction of pipes/pipe joints/pipe fittings, non-detachable pipe connections, passing components, etc., can solve the problems of machinery not working normally, major accidents, inconvenient assembly, etc., and achieve light weight, The effect of high connection strength and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

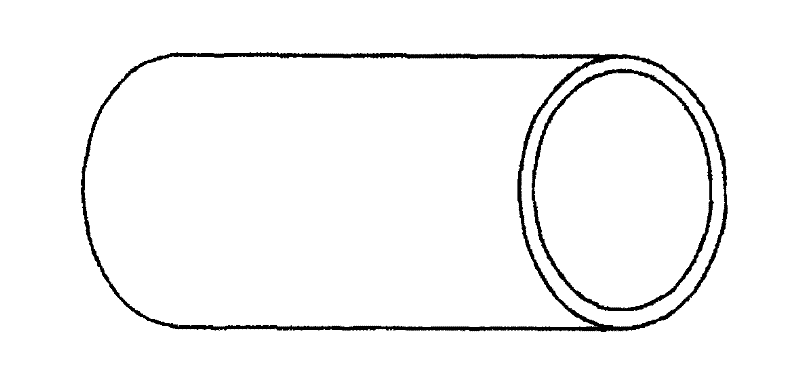

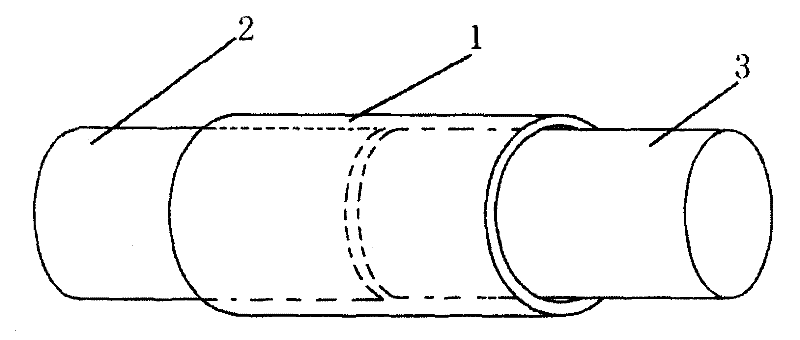

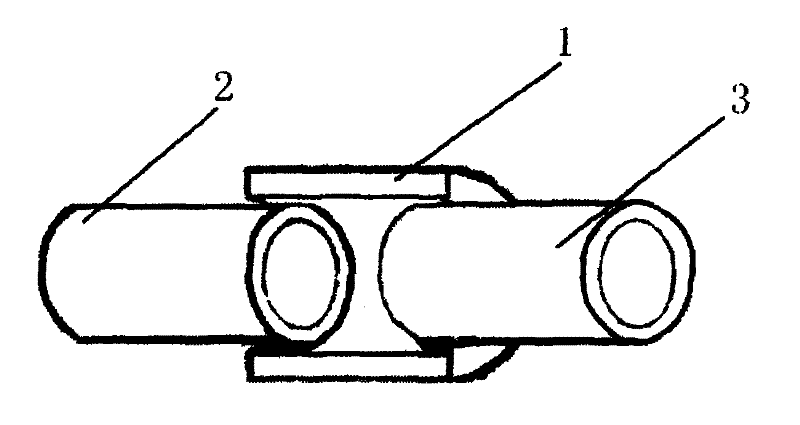

[0014] Such as Figure 1-4 As shown, a hose joint is a new type of pipe joint of the present invention. The pipe joint is made of NiTi alloy as the base material, mainly NiTiNb8.8 alloy, and its diameter is compatible with the diameter of the connected pipe. The requirements of the connecting pipe are made into various specifications. The inner diameter of the pipe joint body is within the range of ф5-98mm, the length is within the range of 8-190mm, the thickness of the pipe wall is 1mm-3mm, and the inside and outside of the pipe are smooth.

[0015] Such as Figure 3-4 As shown, after the pipe joint is selected to be suitable for the pipe diameter of the connected pipe, the wide hysteresis performance of the NiTi alloy is used, and a large amount of interference is formed between the pipe joint 1 and the connected pipes 2 and 3 by using the memory effect. To fit, first align the diameter of the connected pipe in the pipe joint, and then firmly connect the two connected pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap