Rotational flow and direct current combined gas burner

A gas burner and gas fuel technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of air volume change of the lower pulverized coal burner, over-temperature of the screen heating surface, affecting gas fuel burnout, etc. , to avoid energy waste and environmental pollution, low NOx emissions, easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following non-limiting examples illustrate the invention.

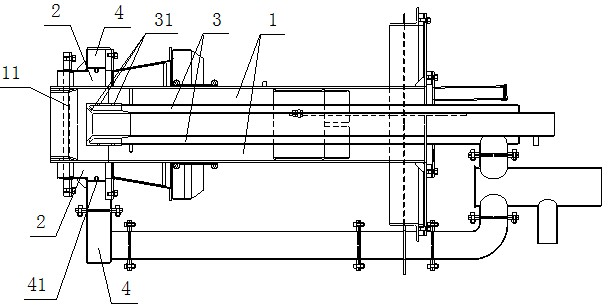

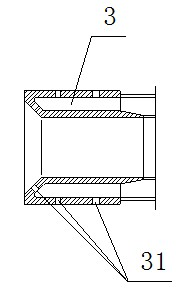

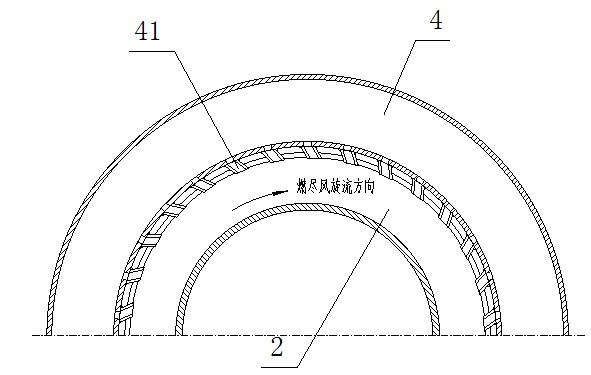

[0026] Such as Figures 1 to 3 As shown, a gas burner of a combination of swirling flow and direct flow includes an overfired air passage through which the overfired air passes and a gas passage through which gas fuel is passed through. The overfired air passage includes a central direct flow air passage 1 and a The outlet 11 of the swirling air passage 2 and the direct-flow air passage 1 is a shrinking type. The gas channel includes a central air intake channel 3 located in the direct air channel 1, the gas fuel sprayed from the front end gas nozzle 31 is mixed with the direct air in the direct air channel 1, and the middle cavity of the central air intake channel 3 is used to place the igniter And the monitoring device also includes a circumferential air intake passage 4 located on the periphery of the swirl wind passage 2, and its front end gas nozzle 41 sprays gas fuel and mixes with the swirl wind in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com