Air-cooling heat pump unit and anti-freezing method for plate heat exchanger

A plate heat exchanger, air-cooled heat pump technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as large differences, affecting the accuracy of the outlet water temperature, and large deviation between the sensor detection temperature and the actual water temperature, to avoid Frost cracked, avoid the effect of anti-freeze failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

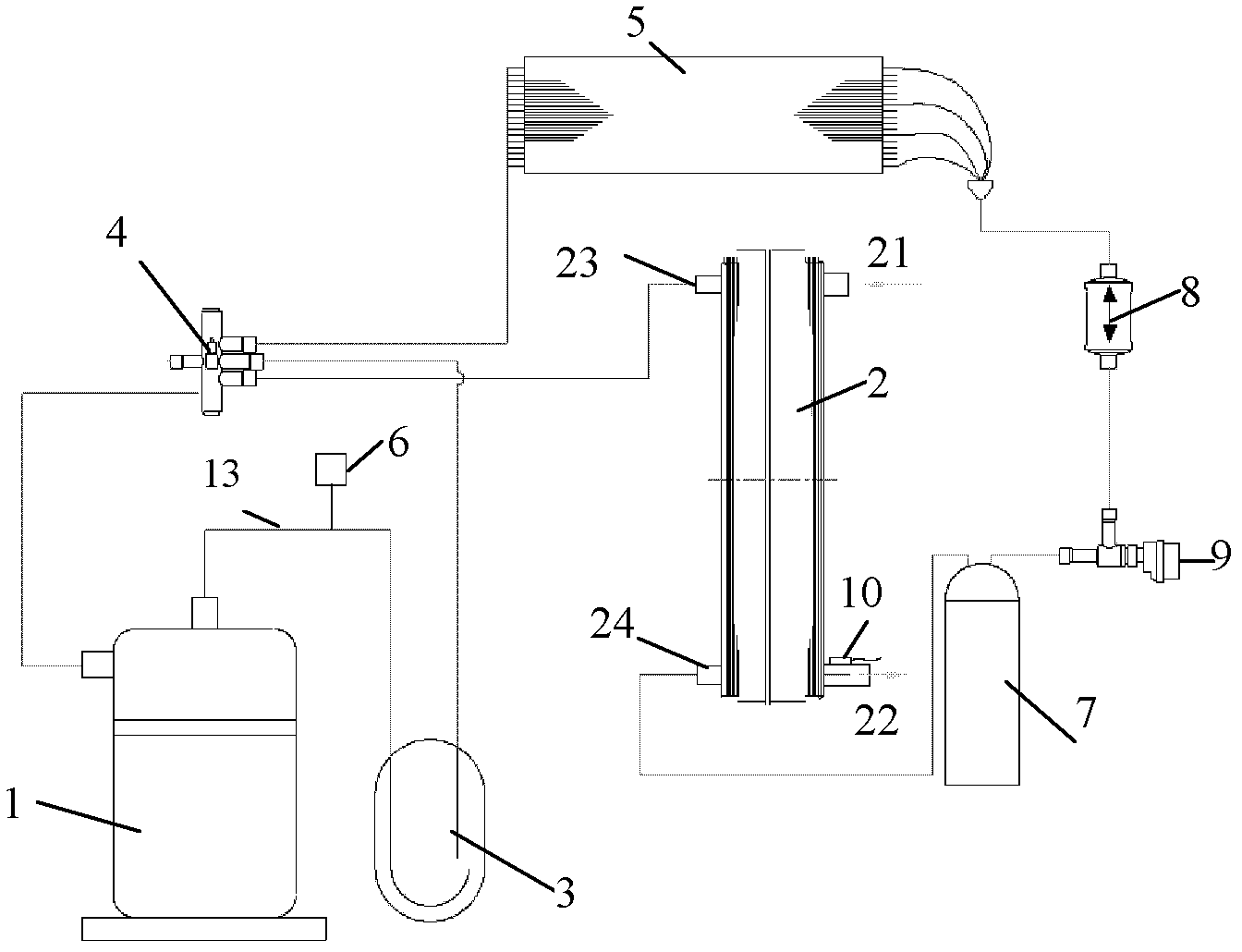

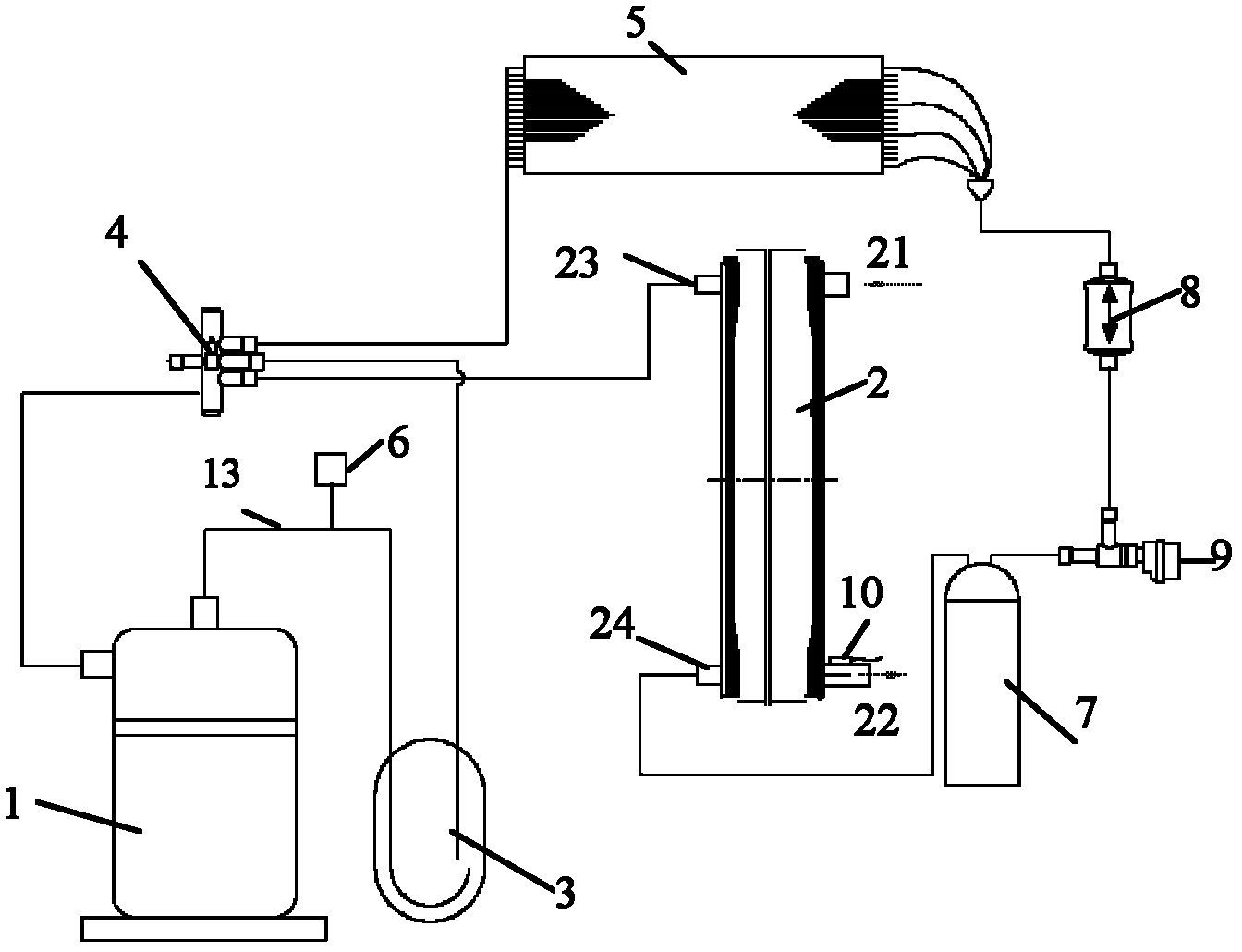

[0021] See attached below figure 1 And attached figure 2 Specific embodiments of the present invention are described.

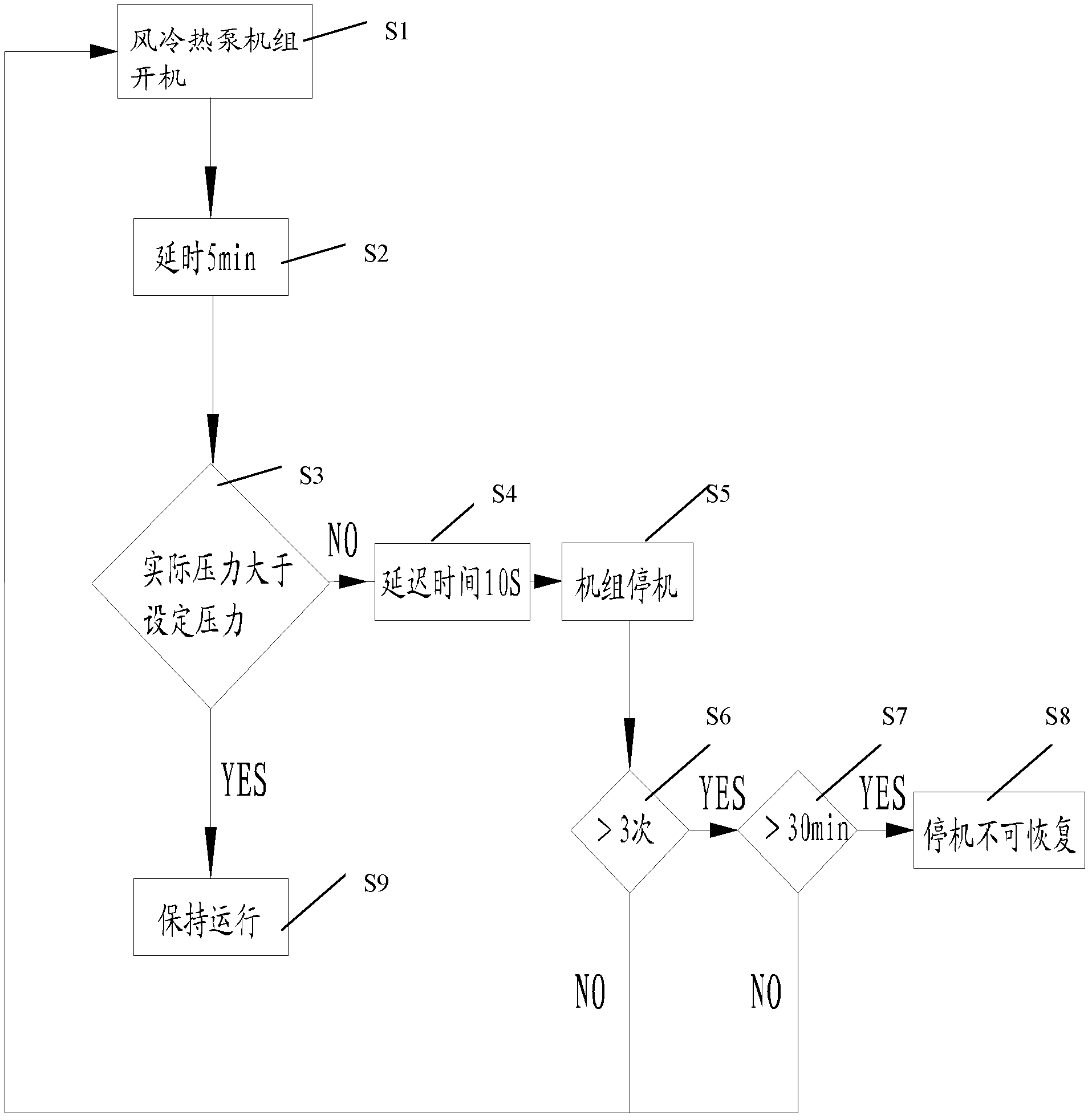

[0022] See attached figure 1 Describe the air-cooled heat pump unit of the present invention, which includes: a compressor 1, a first refrigerant pipeline 13 drawn from the suction port of the compressor 1, and a plate heat exchanger used as an evaporator communicating with the first refrigerant pipeline 13 The device 2, and the pressure sensor 6, wherein the pressure sensor 6 is installed on the first refrigerant pipeline 13 to sense the refrigerant evaporation pressure of the plate heat exchanger 2. The air-cooled heat pump unit of the present invention also includes a controller, and the controller has a module (the first module) for outputting a signal to shut down the air-cooled heat pump unit when the refrigerant evaporation pressure sensed by the pressure sensor 6 is lower than the pressure setting value , wherein the module has a signal output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com