Fastening device for casing of linear encoder

A fixing device and grating ruler technology, applied in the optical field, can solve problems affecting the accuracy of the grating ruler, and achieve the effects of easy processing, easy operation, and guaranteed measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

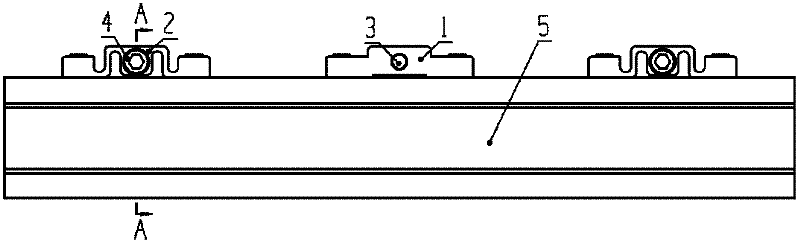

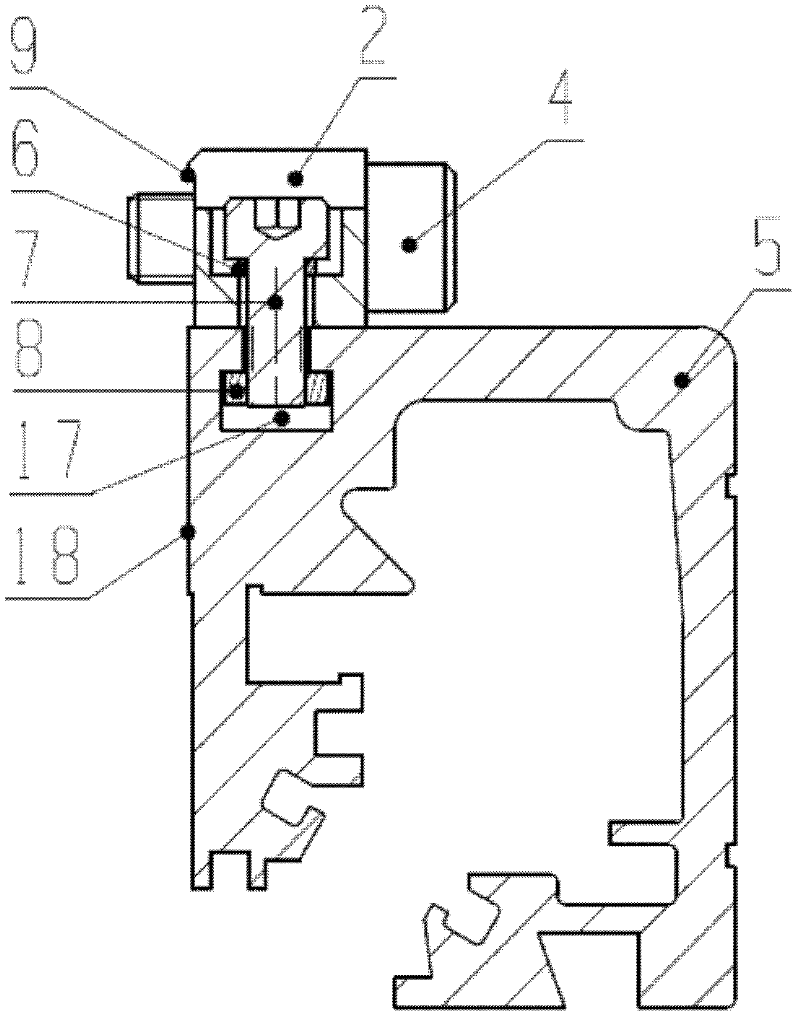

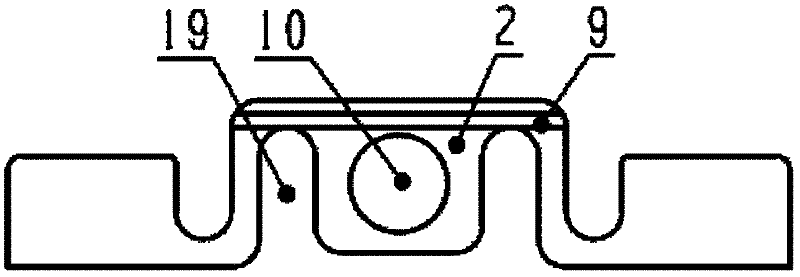

[0020] Such as figure 1 As shown, a rigid scale shell bracket 1 is fixed in the middle of the scale shell 5, which is rigidly connected with the component to be measured through a pin 3; a flexible scale shell bracket 2 is respectively provided on both sides of the rigid scale shell bracket 1, and they are connected by bolts. 4. Flexible connection with the component to be tested. When the scale shell 5 expands and shrinks relative to the member to be measured due to temperature changes, the center of the scale shell 5 will not move due to the rigid scale shell bracket 1. When the temperature rises, the entire scale shell takes the center as the divergence point to the left and right Two directions expand, and when the temperature drops, both sides of the scale shell will shrink inward with the center as the converging point, and the scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com