Tester for pull rod joint of automobile

An automobile tie rod and testing machine technology, which is applied in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc., can solve the problems of high energy consumption, long test period, low accuracy, etc. Easy to use and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or rear, etc., are only for referring to the directions of the attached drawings. Accordingly, the directional terms used are illustrative and not limiting of the present invention.

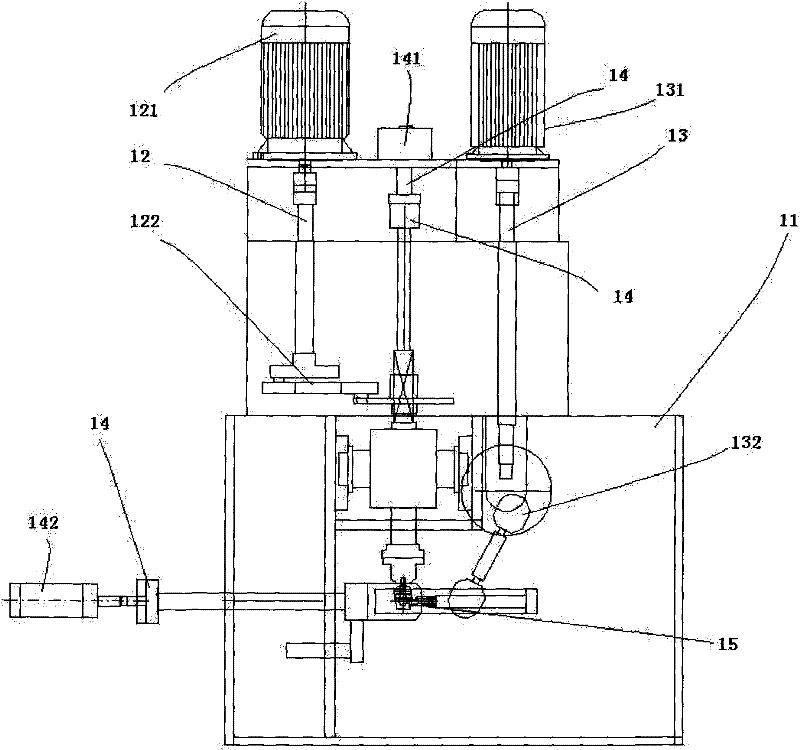

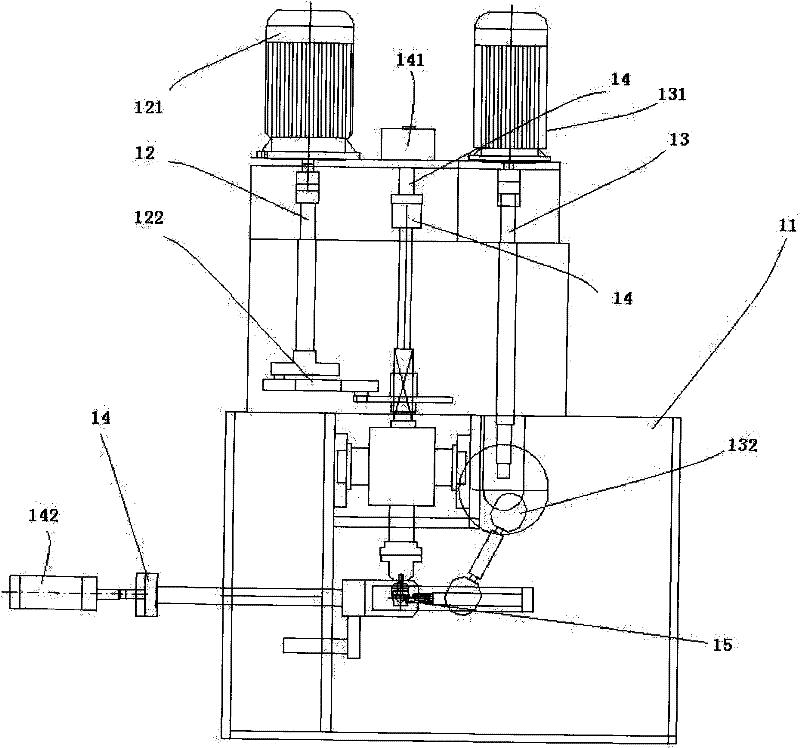

[0014] Please refer to figure 1 As shown, an automobile tie rod joint testing machine 1 according to an embodiment of the present invention includes a frame 11 on which a rotating mechanism 12, a swing mechanism 13 and a load mechanism 14 are arranged, and the rotating mechanism 12 includes a first motor 121 and a transmission mechanism 122, the transmission mechanism 1 is a first crank link mechanism or a gear transmission mechanism, the swing mechanism 13 includes a second motor 131 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com