Testing system for performances of gas cooker

A gas cooker and testing system technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of large human influence, high work intensity, and low precision, and achieve low labor intensity, high labor intensity, The effect of uniform water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

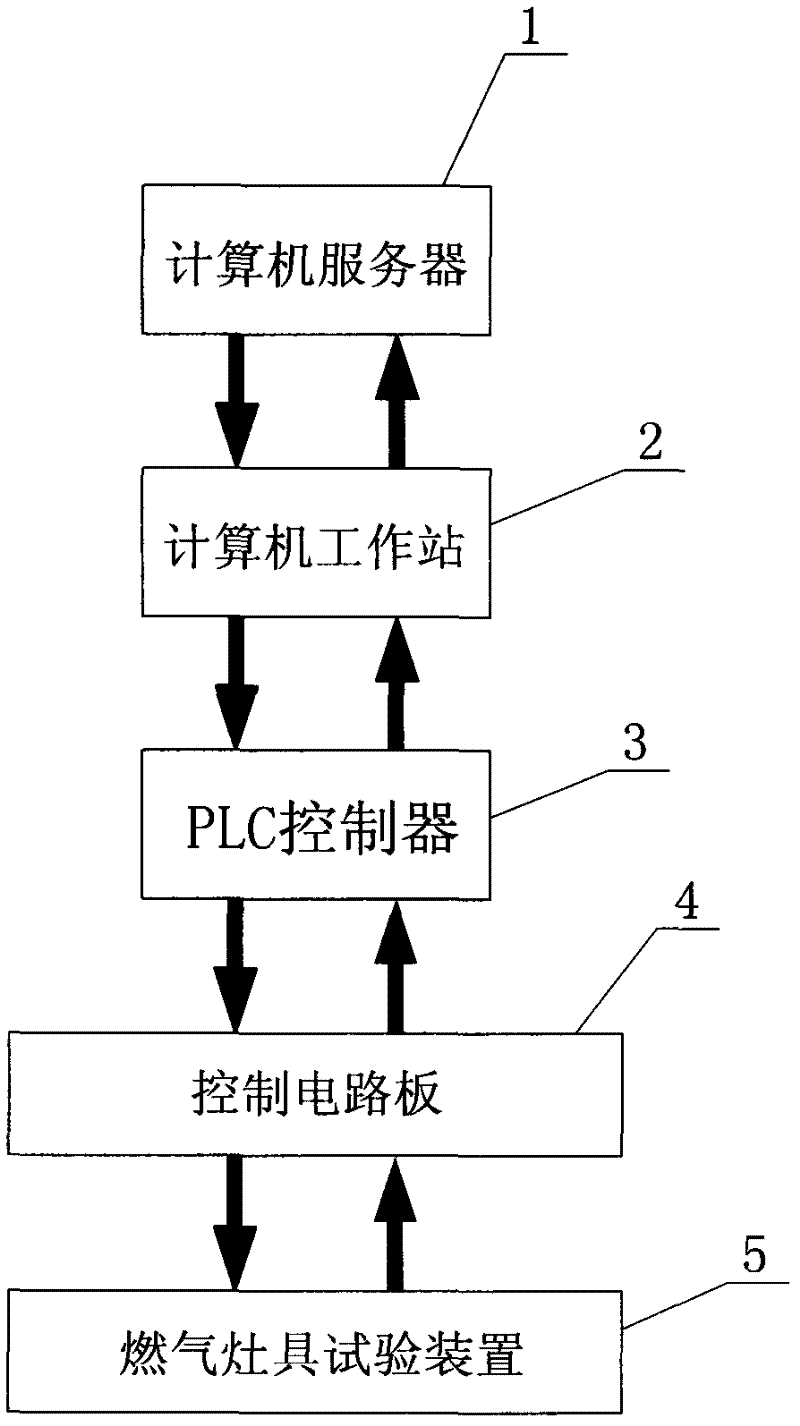

[0026] Such as figure 1 As shown, a gas cooker performance testing system according to the present invention includes a computer server 1, a computer workstation 2, a programmable logic controller 3, a control circuit board 4 and a gas cooker test device 5, wherein

[0027] The computer server 1 is a high-performance computer equipped with a computer operating system and a database software system, and the computer is used to store various experimental data of the gas cooker. Of course, it can also be used for future query management and automatic generation of test reports.

[0028] The computer workstation 2 is a computer equipped with a computer operating system and a gas cooker performance testing software system, the computer provides an operation interface for the user, and the gas cooker performance testing software system in the computer can communicate with the programmable logic controller 3, and The computer network is connected with the computer server 1 to store ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com