Experimental device for measuring mechanical parameter of viscous-elastic material by using shearing method

A material mechanics and experimental device technology, applied in measurement devices, analytical materials, scientific instruments, etc., can solve the problems of complicated use methods, difficult to obtain the resonance peak of the test piece, high price, etc., and achieve simple structure and good test piece adaptability. The effect of high stability and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Describe the present invention below in conjunction with specific embodiment:

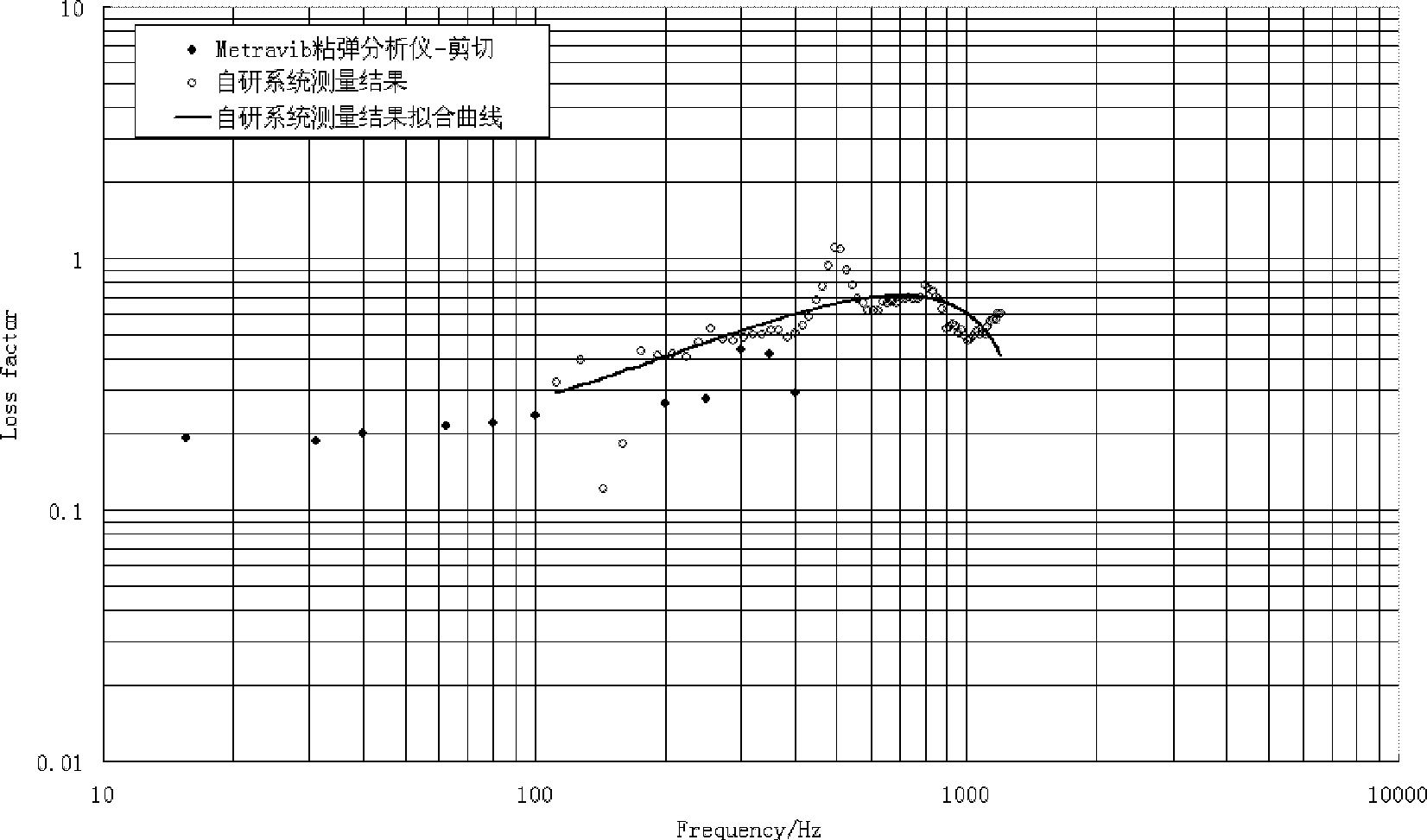

[0016] In this embodiment, the loss factor of the specimen material is measured by using an experimental device for measuring the mechanical parameters of the viscoelastic material by using the shear method.

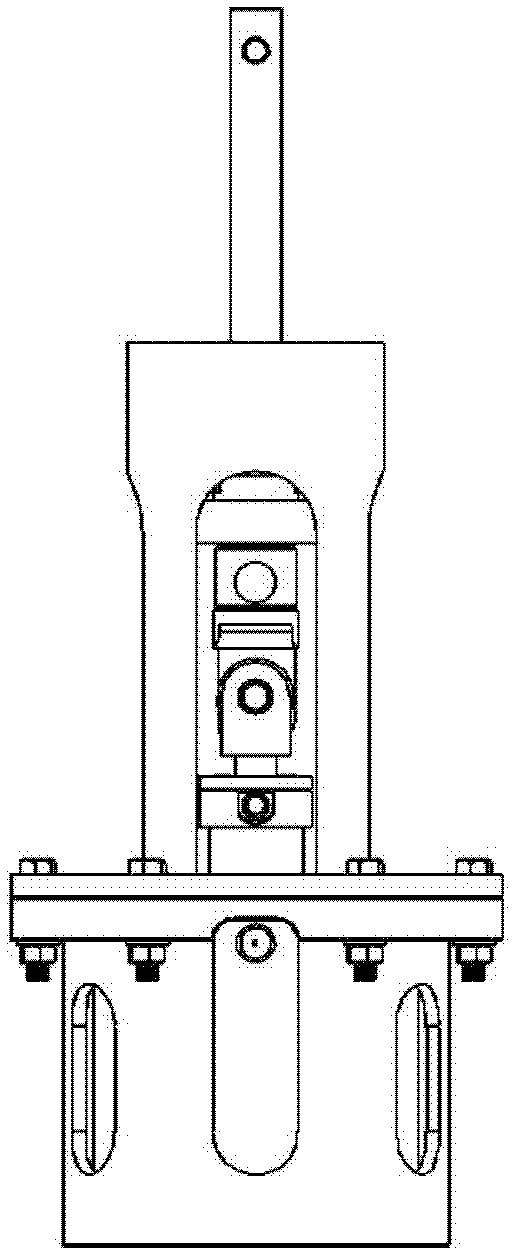

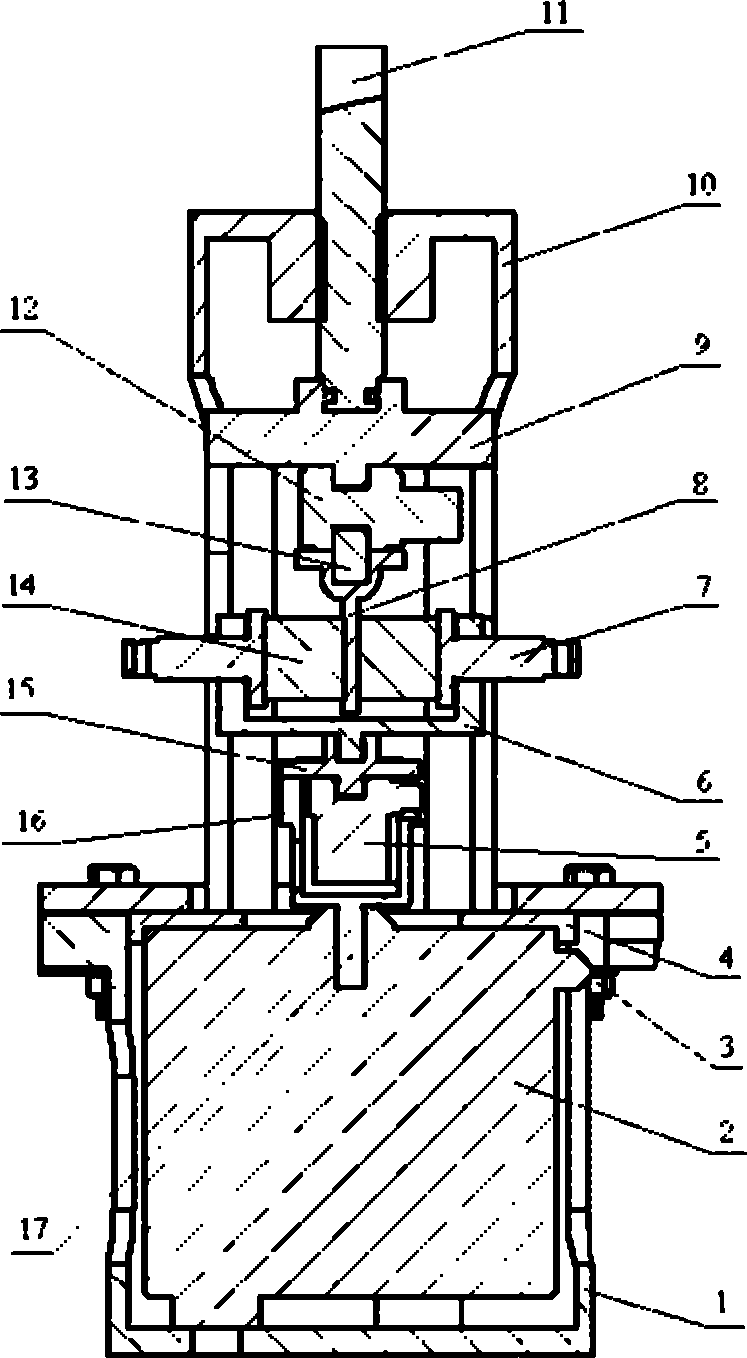

[0017] Refer to attached figure 2 , this embodiment includes a housing, a force sensor 12 , an acceleration sensor 5 and a vibrator 2 .

[0018] The shell is divided into an upper shell 10 and a lower shell 1. Both the upper shell and the lower shell are hollow cylindrical structures with one end closed. The upper shell and the lower shell are coaxial and fixedly connected by fastening bolts 3; The vibrator is placed inside the lower case, and the auxiliary gasket 4 is placed between the vibrator and the lower case, and the central axis of the vibrator is collinear with the central axis of the lower case.

[0019] There is a central through hole on the upper end surface of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com