Light aging testing method for composite core rod

A technology for composite material core and aging test, which is applied in the direction of analysis materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc. The effects of perfect assessment, good test reliability and high degree of simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

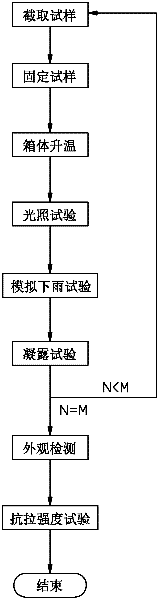

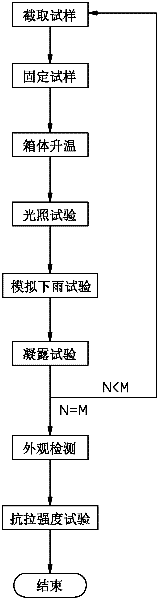

[0022] refer to figure 1 , the light aging test method of composite core rod, it is characterized in that carry out according to the following steps:

[0023] 1) Cut the sample: Cut the composite material mandrel into a sample with a length of 1200mm. Since it is necessary to test the mechanical properties after light aging, in order to meet the requirements of the sample length for the mechanical properties test, the length of the mandrel is made to be 1200mm here.

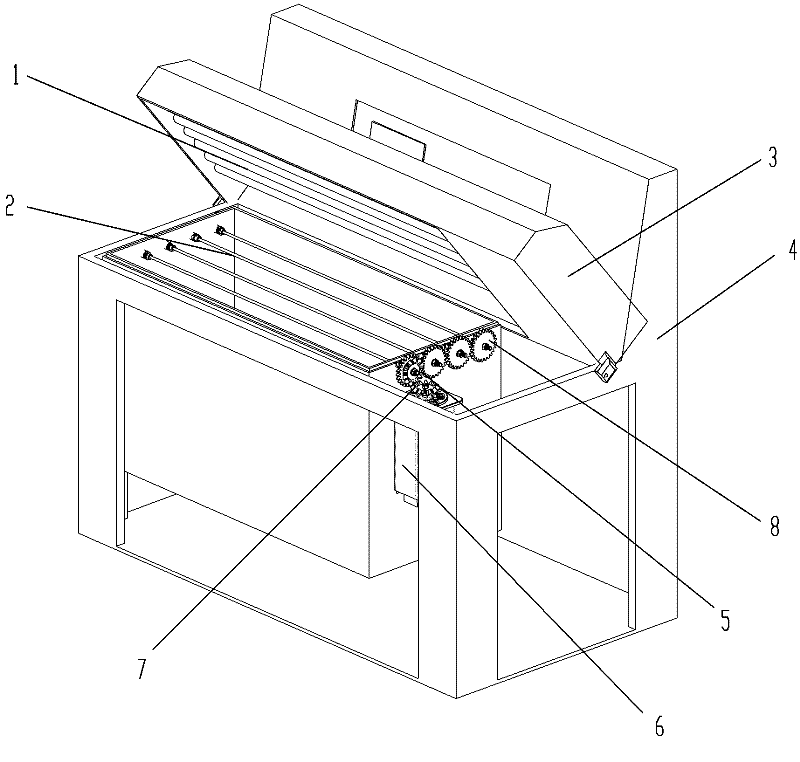

[0024] 2) Fix the sample: put the sample into the special clamping seat that is matched in the light aging test box, and the sample will be driven by the clamping seat to rotate at a uniform speed in the circumferential direction during the test.

[0025] 3) Warming up of the cabinet: heating up the cabinet, keeping the temperature at 80° C. and the humidity at 50%. The temperature and humidity are determined according to the actual working environment of the composite mandrel.

[0026] 4) Illumination test: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com