Processing program interpreter implementation method for numerical control system with single motor to drive multiple shafts

A single-motor drive, processing program technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as inapplicability to machine tools, and achieve the effects of reducing switching axis time, correct and efficient operation, and improving execution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

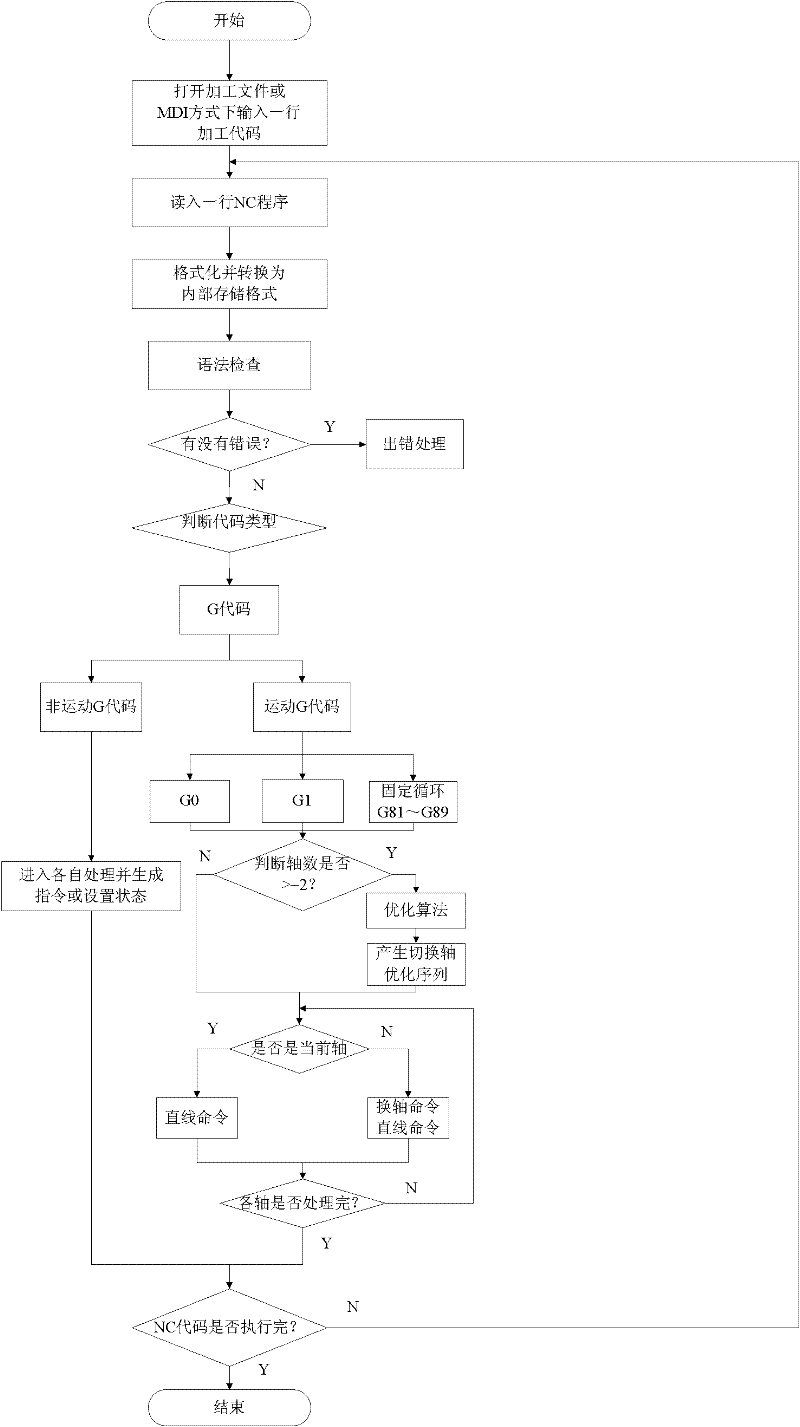

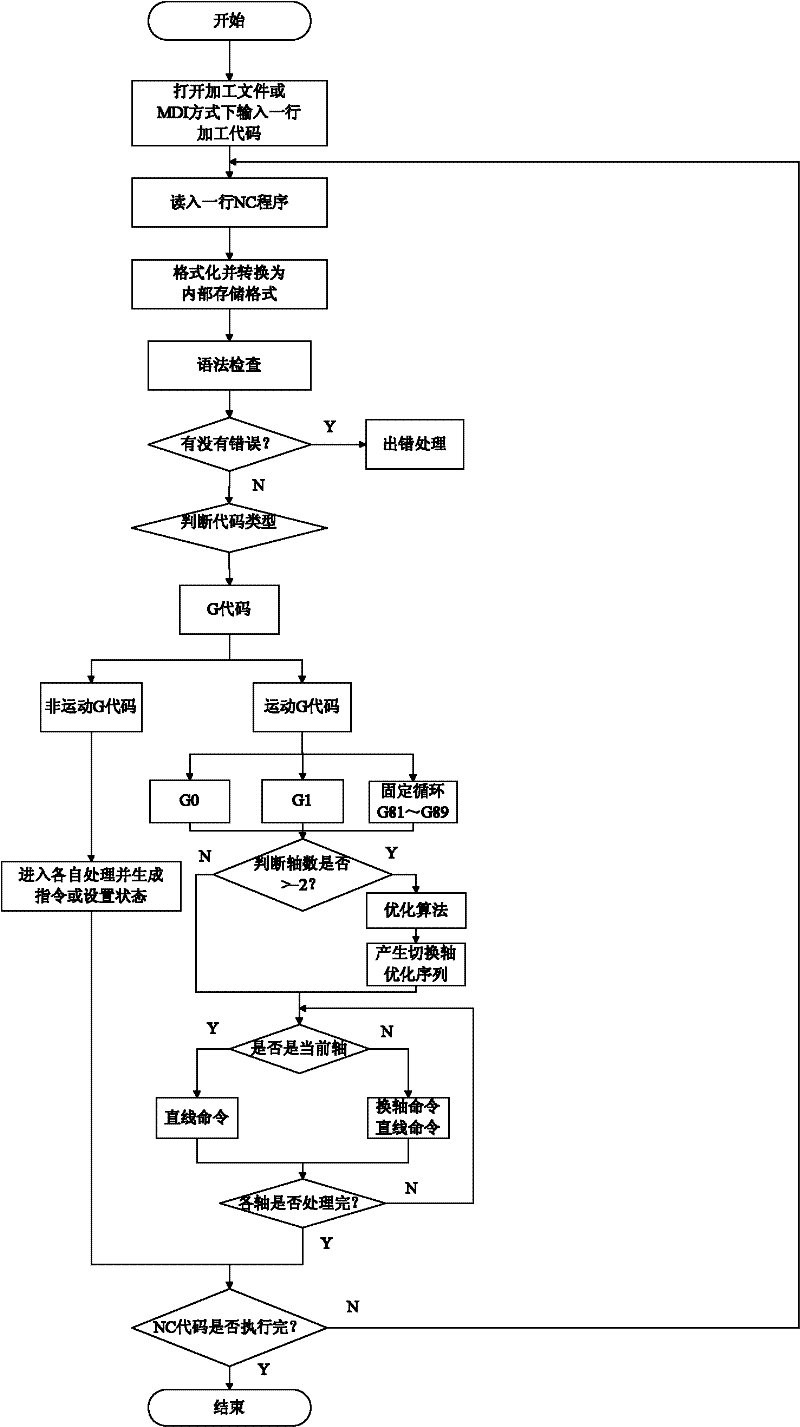

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] When an interpreter processes a one-line processing program, it mainly goes through two stages: syntax analysis and interpretation and execution. Specifically, after the interpreter reads a line of processing code, it needs to complete the work of reading information, formatting, error checking, and saving it in an internal format to prepare for further processing. CNC machine tools usually use G code to describe the processing information of the machine tool, such as tool path, coordinate system selection, etc., and also include auxiliary information codes such as M, F, S, T, etc., and interpret G code as a command format that the CNC system can recognize It is the main function of the processing program interpreter.

[0033] figure 1 It is a flow chart of the implementation method of the numerical control system processing program interpreter drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com