Intelligent temperature and humidity controller

A technology of humidity controller and temperature and humidity sensor, applied in non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve problems such as low accuracy, poor accuracy, and reduced measurement accuracy, and achieve response speed Fast, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

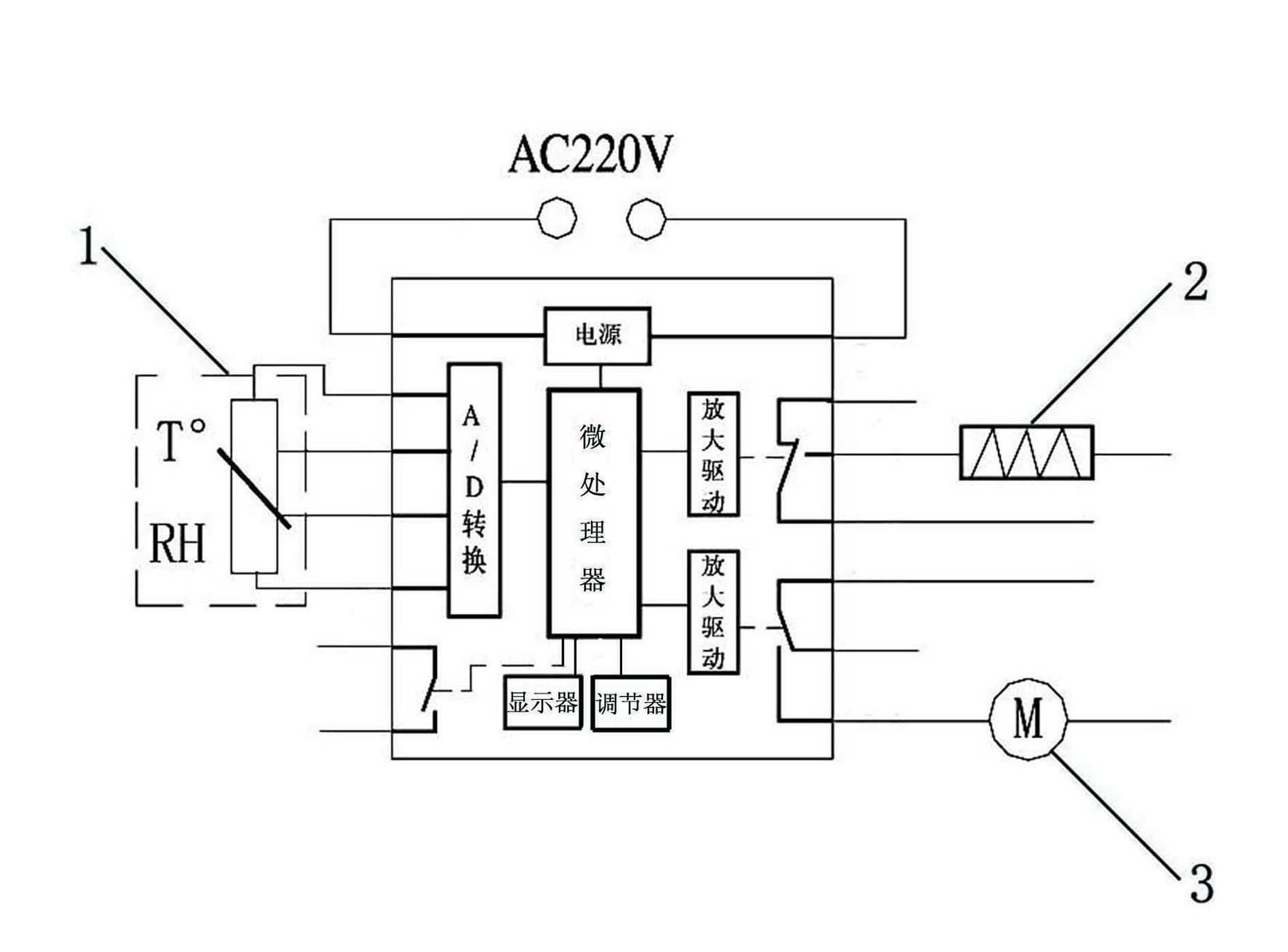

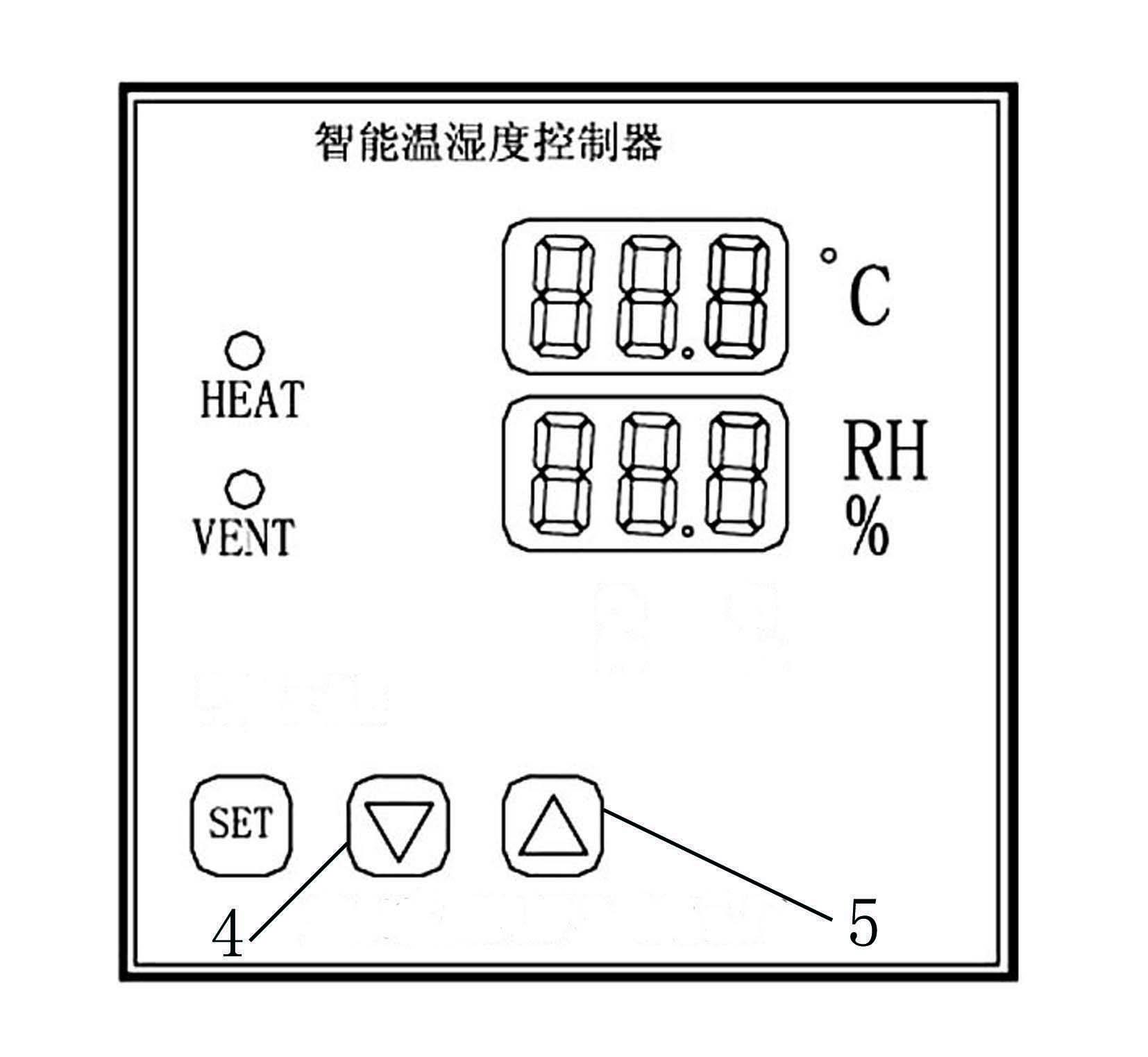

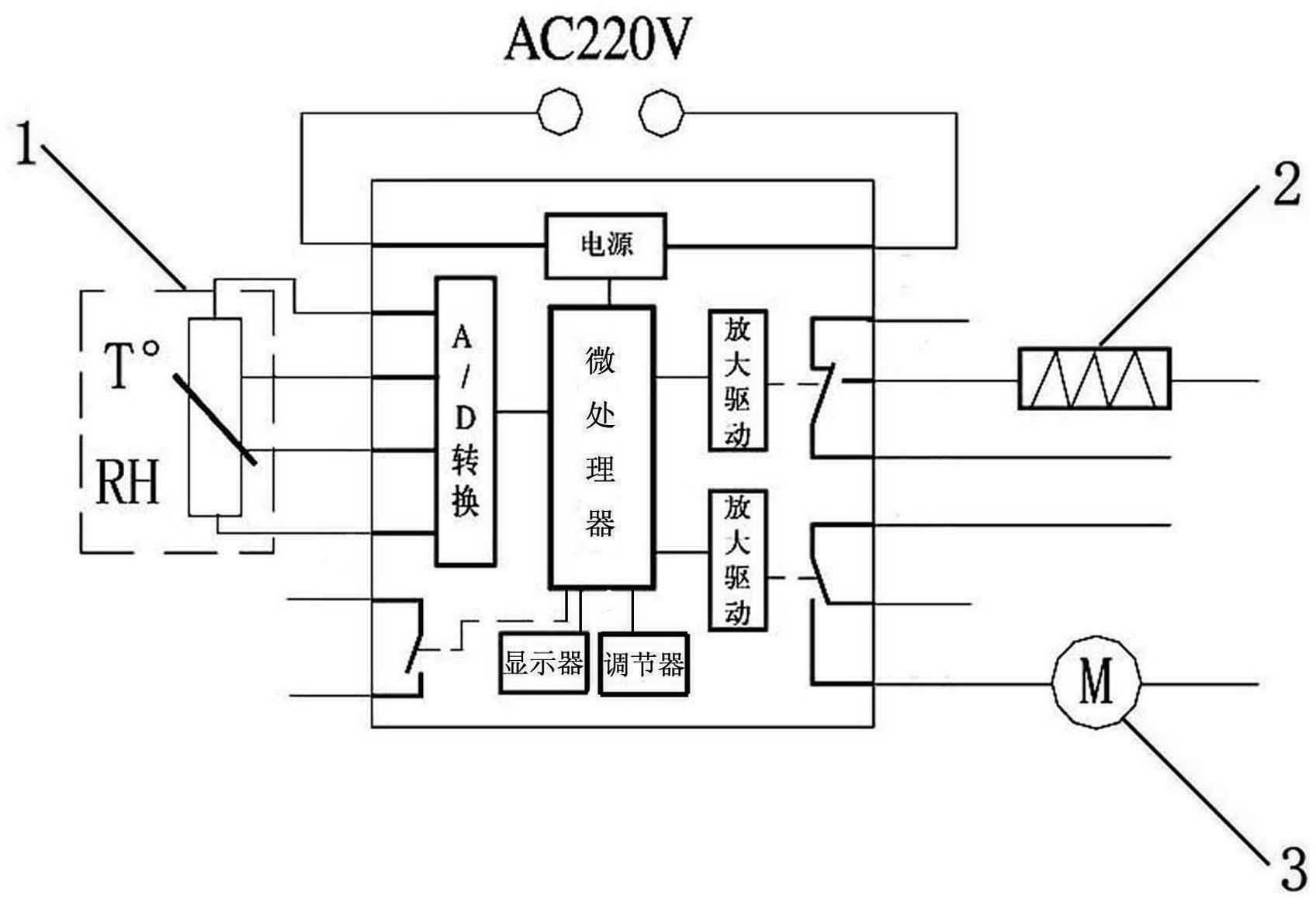

[0015] In order to further disclose the technical solution of the present invention, the implementation mode of the present invention will be described in detail in conjunction with the accompanying drawings: figure 1 As shown, an intelligent temperature and humidity controller includes a casing, a power supply, a temperature and humidity sensor 1, a microprocessor, an execution module and a display system, the execution module is a heater 2 and a fan 3, and the display system is to display the current temperature value, humidity LED display for values and setting information. The temperature and humidity sensor 1 is connected to the microprocessor through the A / D converter, one end of the microprocessor is connected to the power supply, and the other end is connected to the display system, and an amplifying driver is connected between the microprocessor and the execution module. A digital regulator is also connected. There is a panel for setting temperature and humidity in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com