Redundant metal filling method and system utilizing same

A filling method and redundant metal technology, applied in the direction of instruments, computing, electrical digital data processing, etc., can solve the problem of not being able to take into account the calculation accuracy of redundant metal filling, and not being able to well reduce the difference in density of different pane regions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

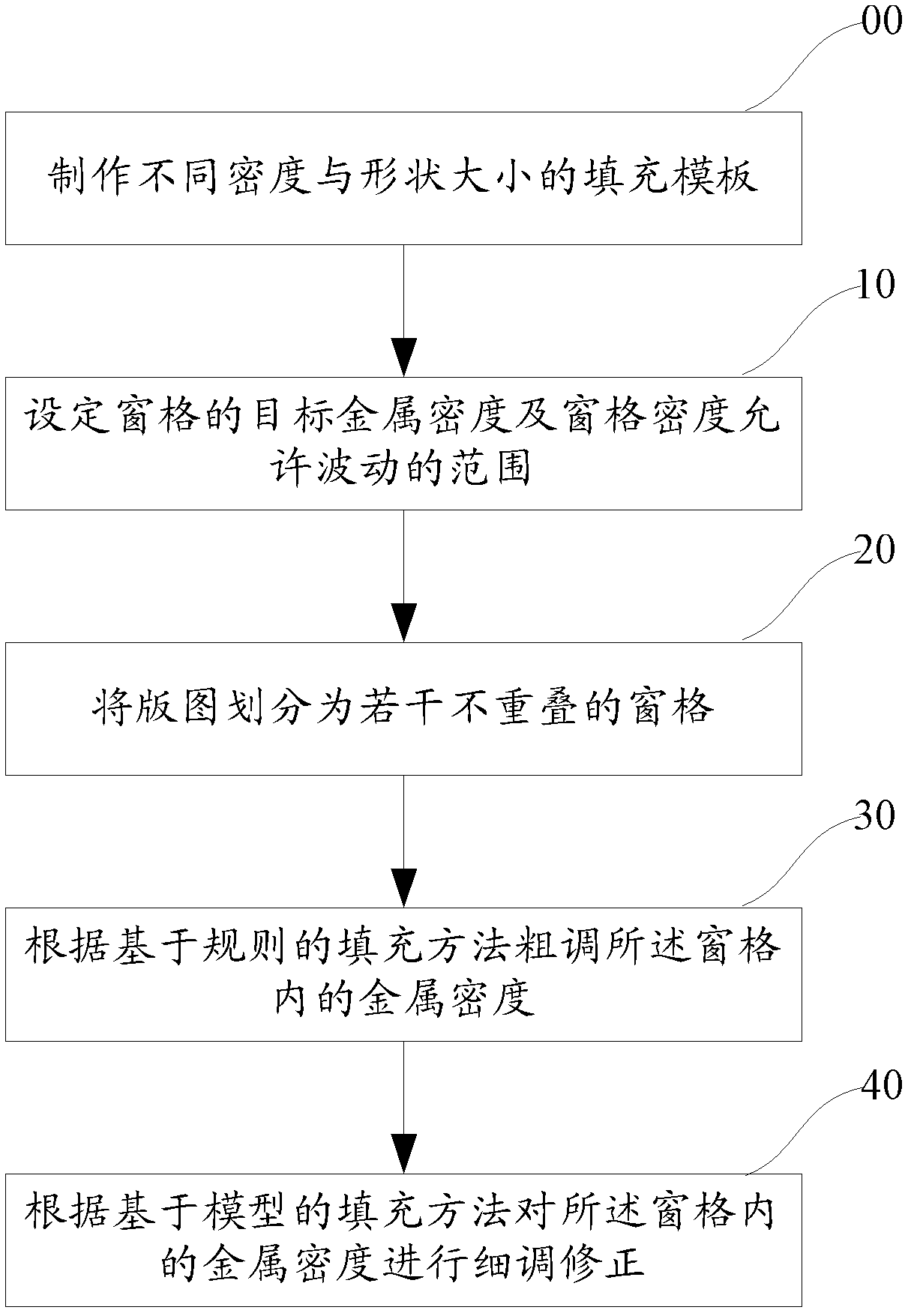

[0016] see figure 1 , a redundant metal filling method provided by an embodiment of the present invention includes the following steps:

[0017] Step 00, making a template library containing filling templates of different densities and shapes and sizes and a graphic library including filling blocks of different densities and shapes and sizes.

[0018] Step 10. Set the target metal density D of the pane 1 , The allowable fluctuating range ΔD of the pane density.

[0019] Step 20. Divide the layout into several non-overlapping panes, mark them, and equally divide them into m×n small blocks with side length a.

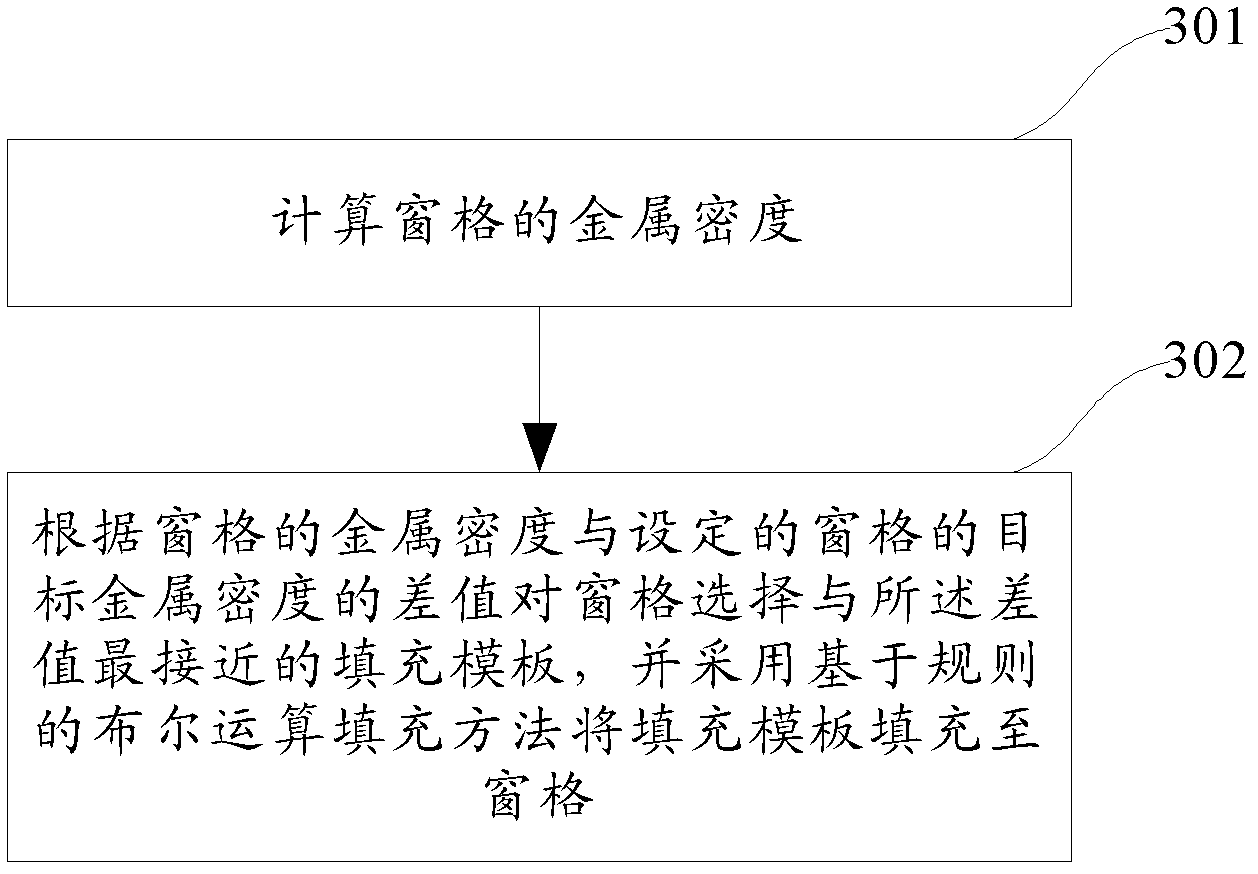

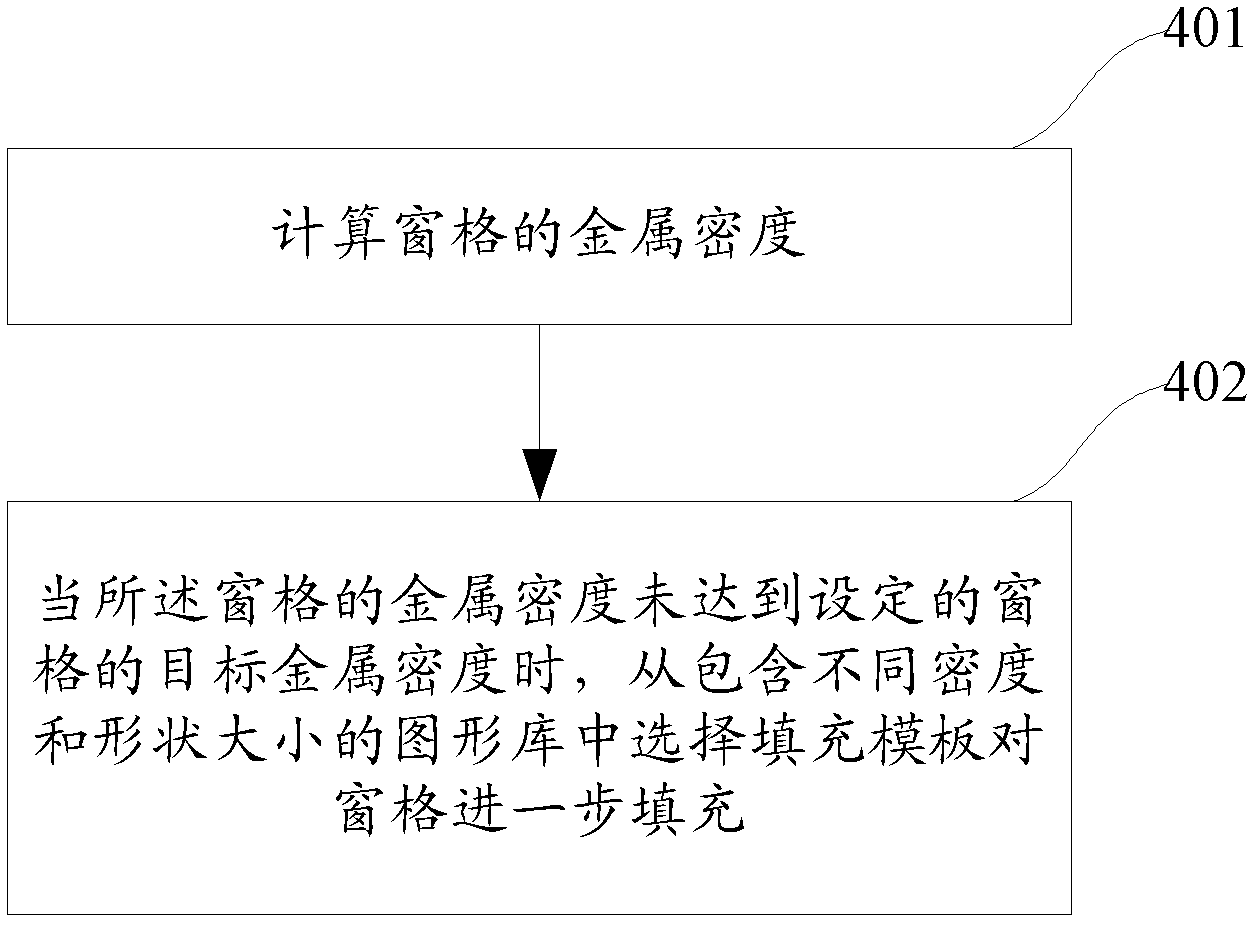

[0020] Step 30, roughly adjust the metal density in the pane according to the rule-based filling method. Among them, the rule-based filling method is to obtain better density uniformity, thereby reducing the surface thickness variation after CMP. This method is filled according to the design rules proposed by the craft factory, etc., such as layout density must be abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com