Reactor irradiation hydraulic driving device

A hydraulic drive and internal irradiation technology, applied in irradiation devices, nuclear engineering, etc., can solve problems such as oil spills and polluted pool water, and achieve the effects of improving operating efficiency, reliable rotating operation, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The hydraulic driving device for in-core irradiation provided by the present invention includes a power generation module and a drive module for driving the rotation of the parts that hold the irradiation elements, the power generation module is arranged above the reactor pool, and the drive module is arranged in the reactor pool and the drive module is an oil-free lubricated hydraulic drive module; it also includes a power transmission module arranged between the power generation module and the hydraulic drive module.

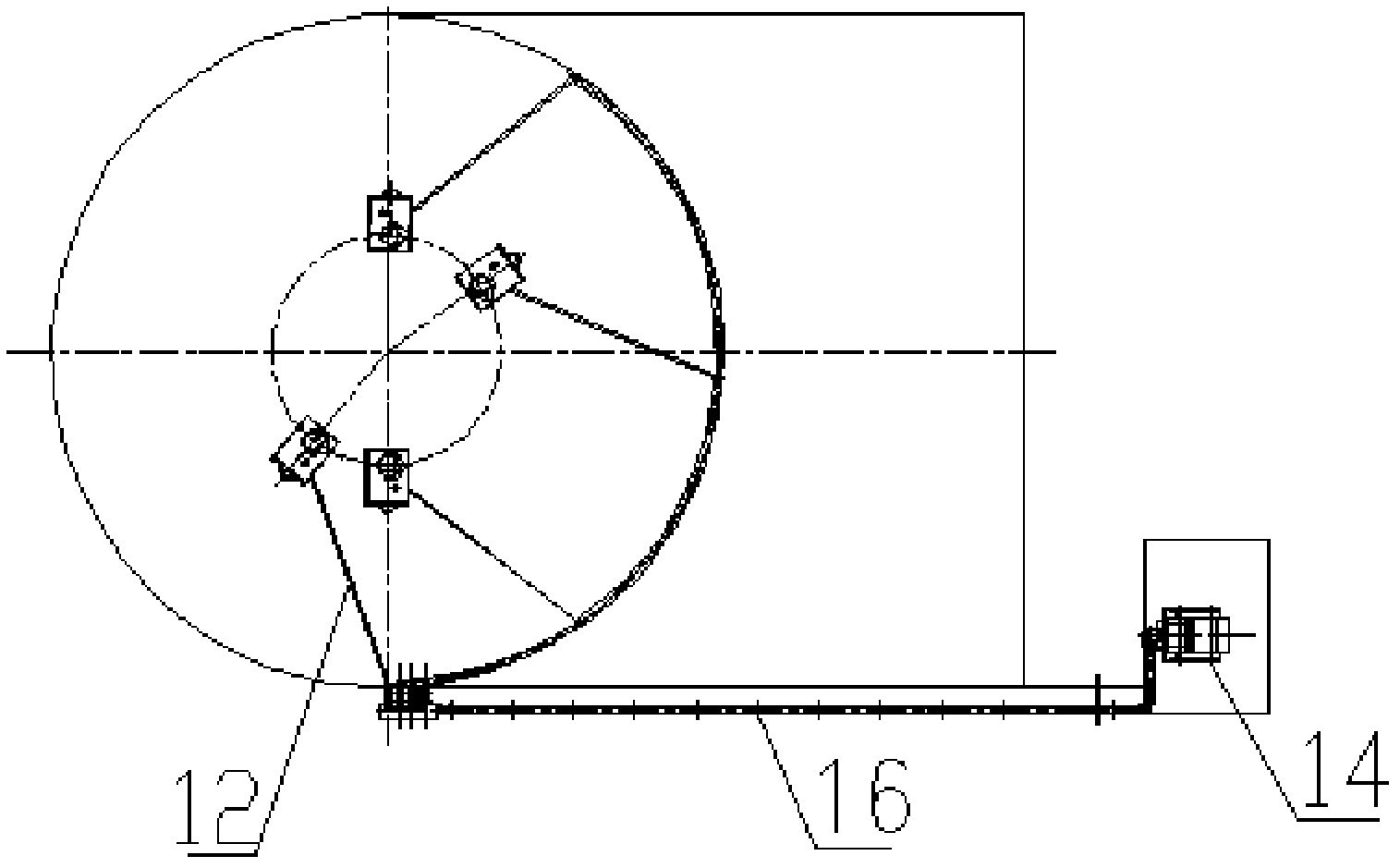

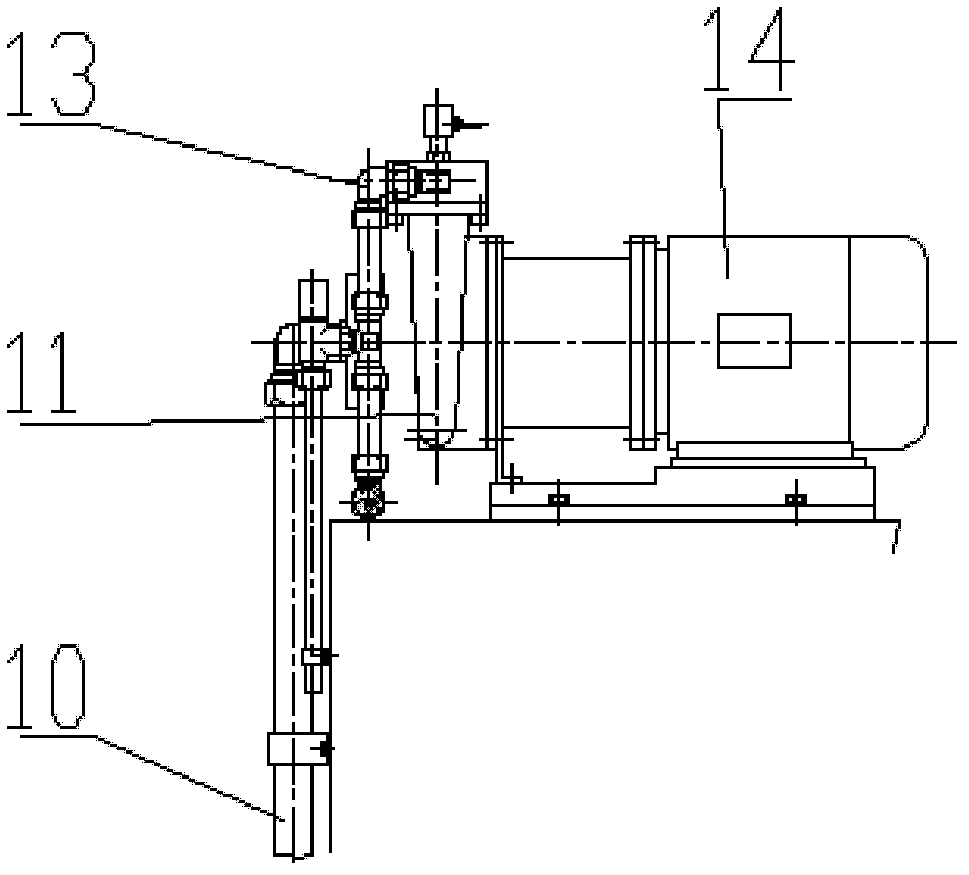

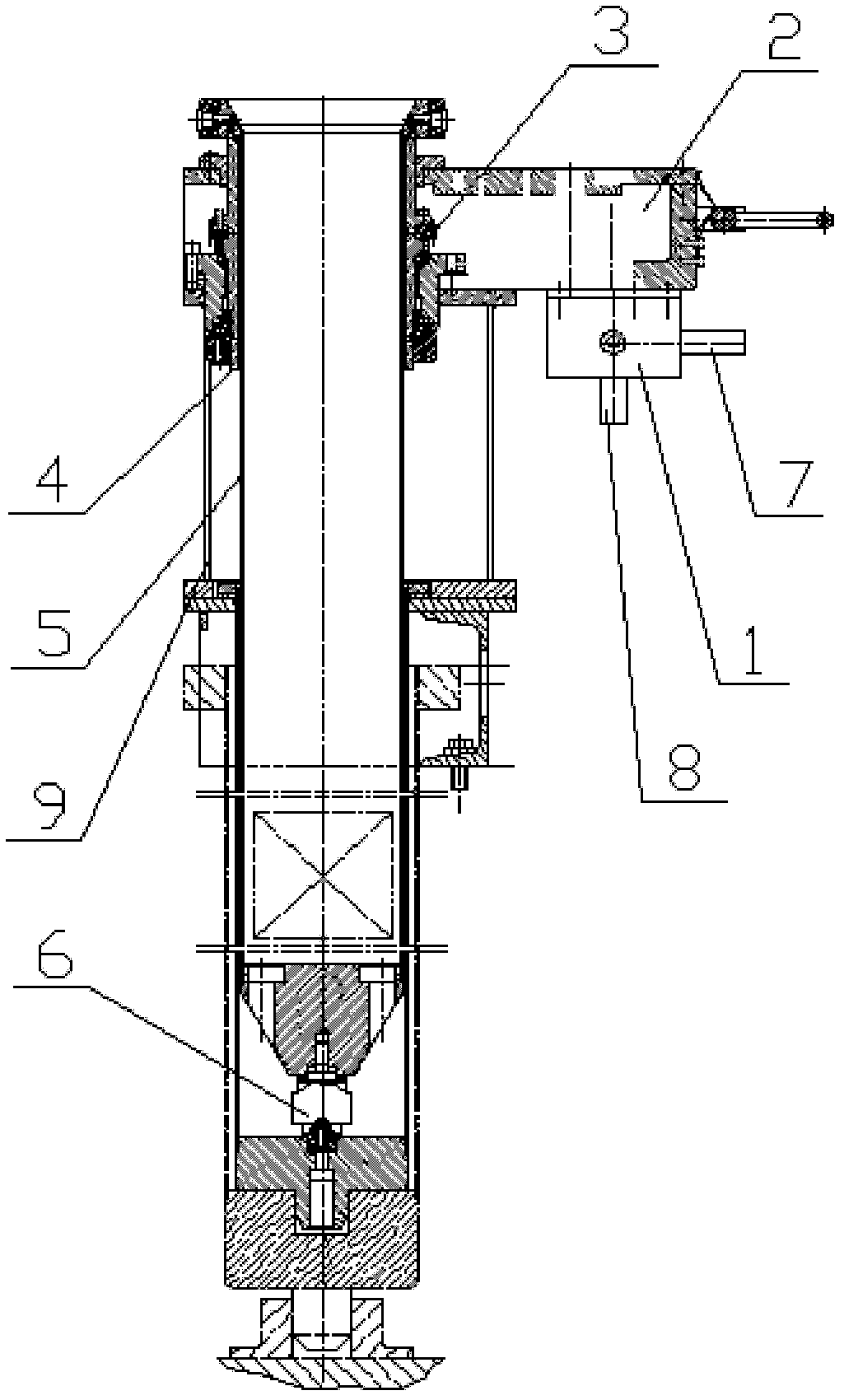

[0028] Such as figure 1 , figure 2 As shown, the power generating module includes a motor 14 and a centrifugal water pump 11 connected thereto, and the power delivery module includes a connecting pipe 16 and a driving water pipe 12 . Such as image 3 As shown, the hydraulic drive module includes a fixed bracket 9, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com