Tubular wire-stranding machine with twisted bow

A technology of stranding machine and twisting bow, which is applied in the field of tubular stranding machine, can solve the limitations and other problems, and achieve the effects of less wear of parts, long service life and uniform twisting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

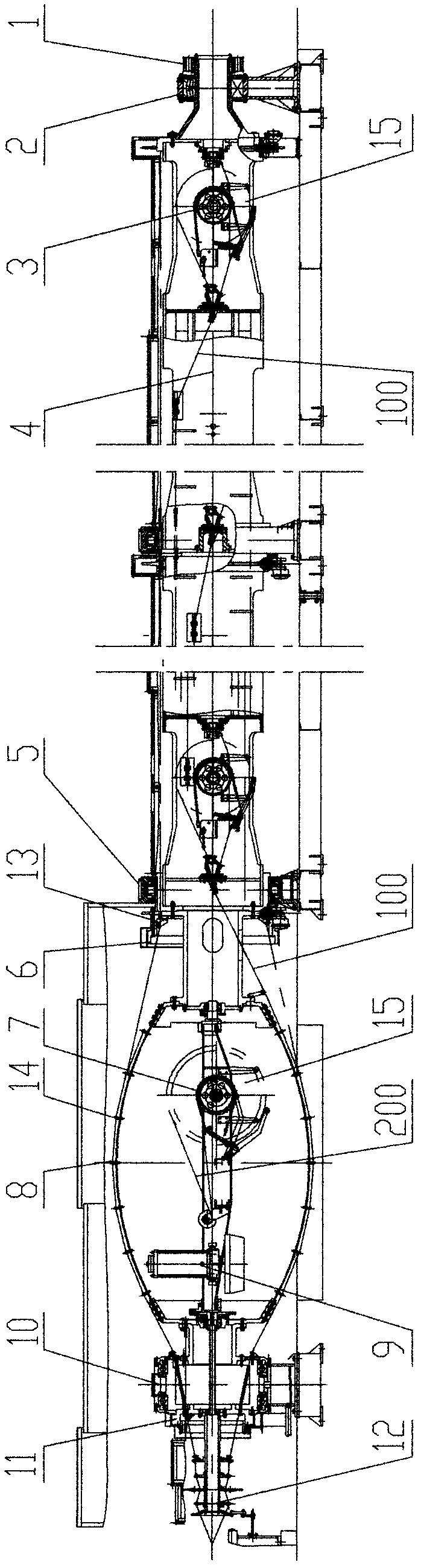

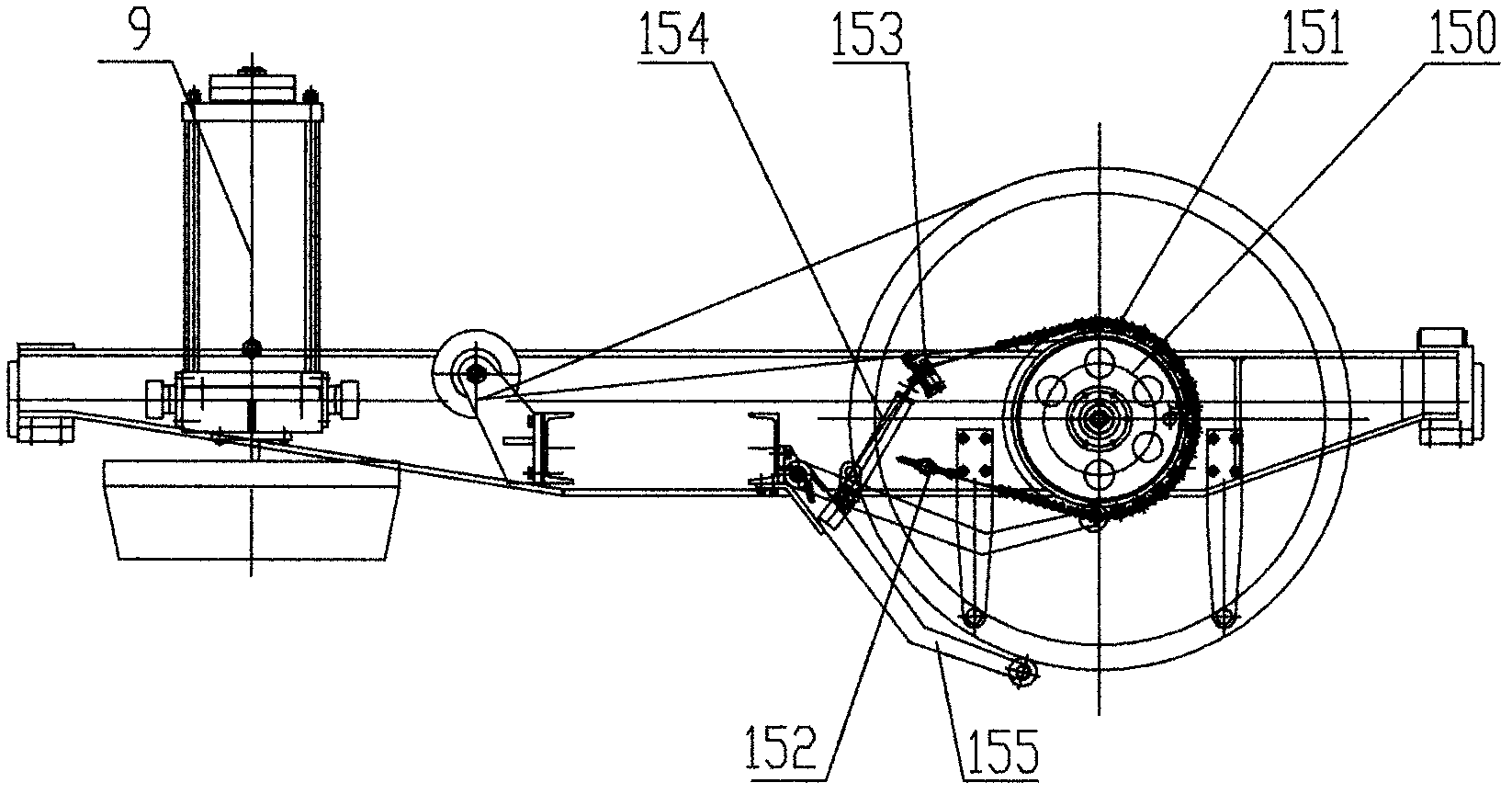

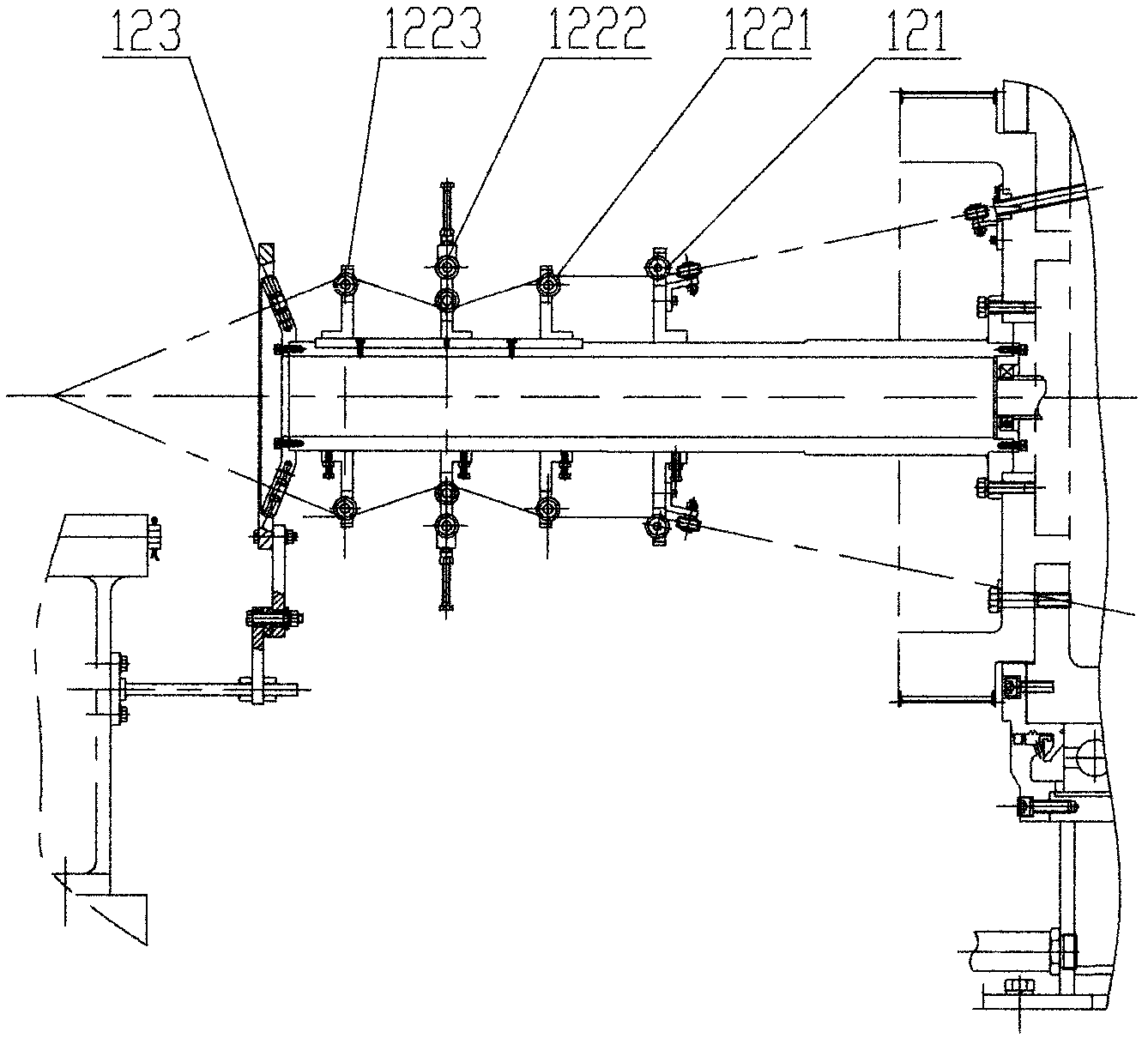

[0021] Examples, see figure 1 Shown: Tubular stranding machine with twisting bow for twisting steel wire 100 on a straight core wire 200. The tubular stranding machine with a twisting bow includes: at least one cylinder body 4 pulleys, a rear support 2, at least two wire reel frames, a bearing seat 5, a front support 10, and a single wire preforming device 12 connected together. Among them, the wire coil racks are divided into two types, namely steel wire coil racks 3 and core wire coil racks 7 . Wherein, the steel wire reel frame 3 is located in the cylinder body 4 for releasing the steel wire 100 . The core wire reel frame 7 is located between the leftmost cylinder body 4 and the front support 10 and is used for releasing the core wire 200 . At the same time, at least two twisted bows 8 are provided on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com