Method for producing yarn using a ring spinning frame, and ring spinning frame

A spinning frame and yarn technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve the problem of changing the number and size of balloons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

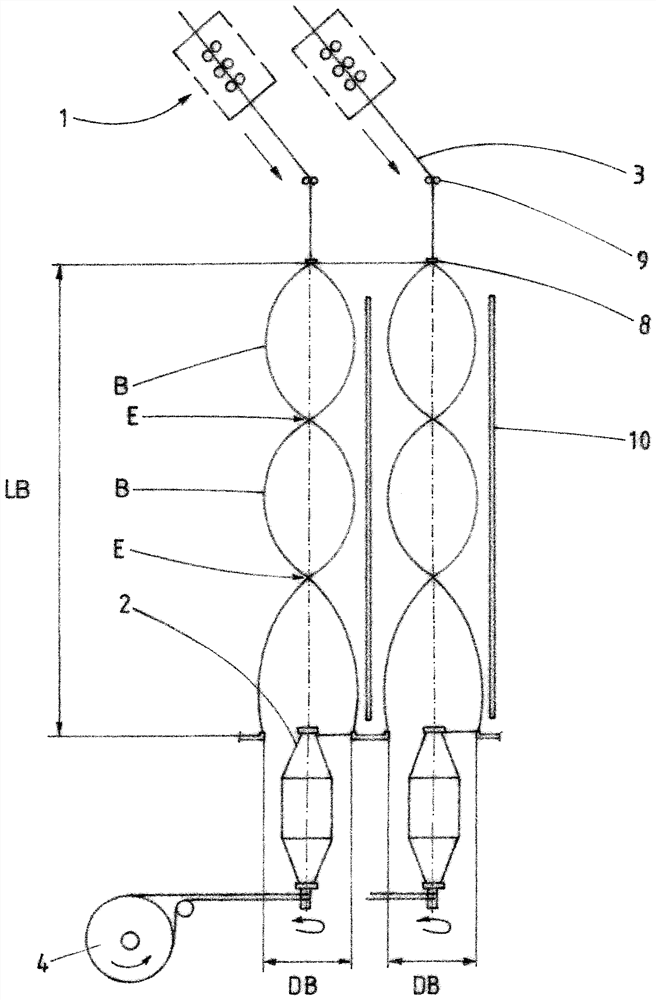

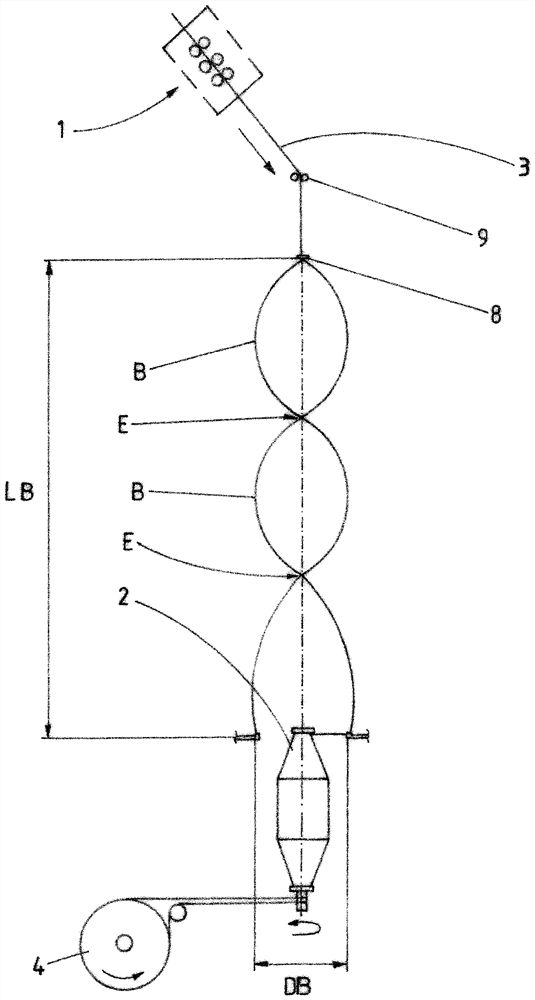

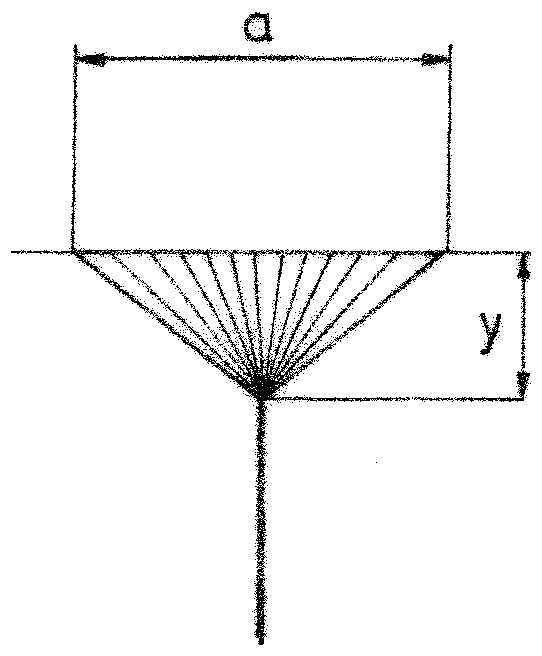

[0029] exist figure 1 , figure 2 A spinning station of a ring spinning frame (not shown) is schematically shown in . In the present method for producing yarn at a spinning station, the fiber composite material 3 is fed to the drafting system 1 and drawn as it passes through the drafting system 1 . The fiber composite material 3 is guided over the thread guide 8 and through the rotating traveler 5 , wherein the traveler 5 rests on the ring 6 , wherein the fiber composite material 8 is twisted and a yarn 12 is produced, and the yarn 12 is wound onto a sleeve 2 which is placed on a rotating spindle. The spindle 2 is driven by a spindle drive 4, which can be a single-spindle drive. In the specified method, the ring 6 is on a fixed ring plate and the spindle 2 is on a moving spindle rail.

[0030] as from figure 1 , figure 2It can be seen that in this case a helical path E of the fiber composite material 8 with two complete balloons B is produced between the thread guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com