Method for packaging chip based on epoxy resin type adhesive

An epoxy resin and chip packaging technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of chip warping, chip large stress, tearing, etc., and achieve the reduction of unbonded areas and voids , Improved stability and reliability, and low residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

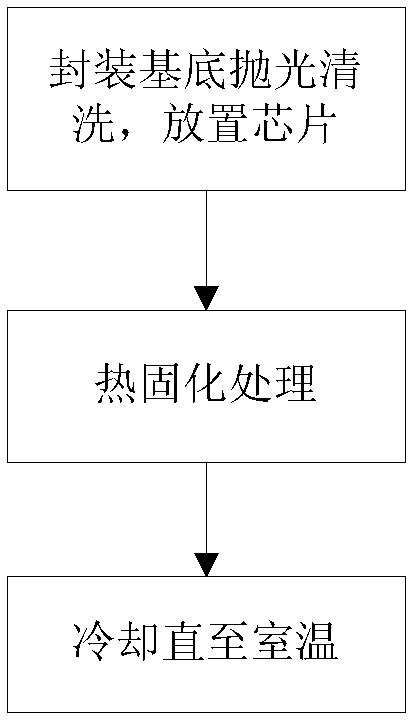

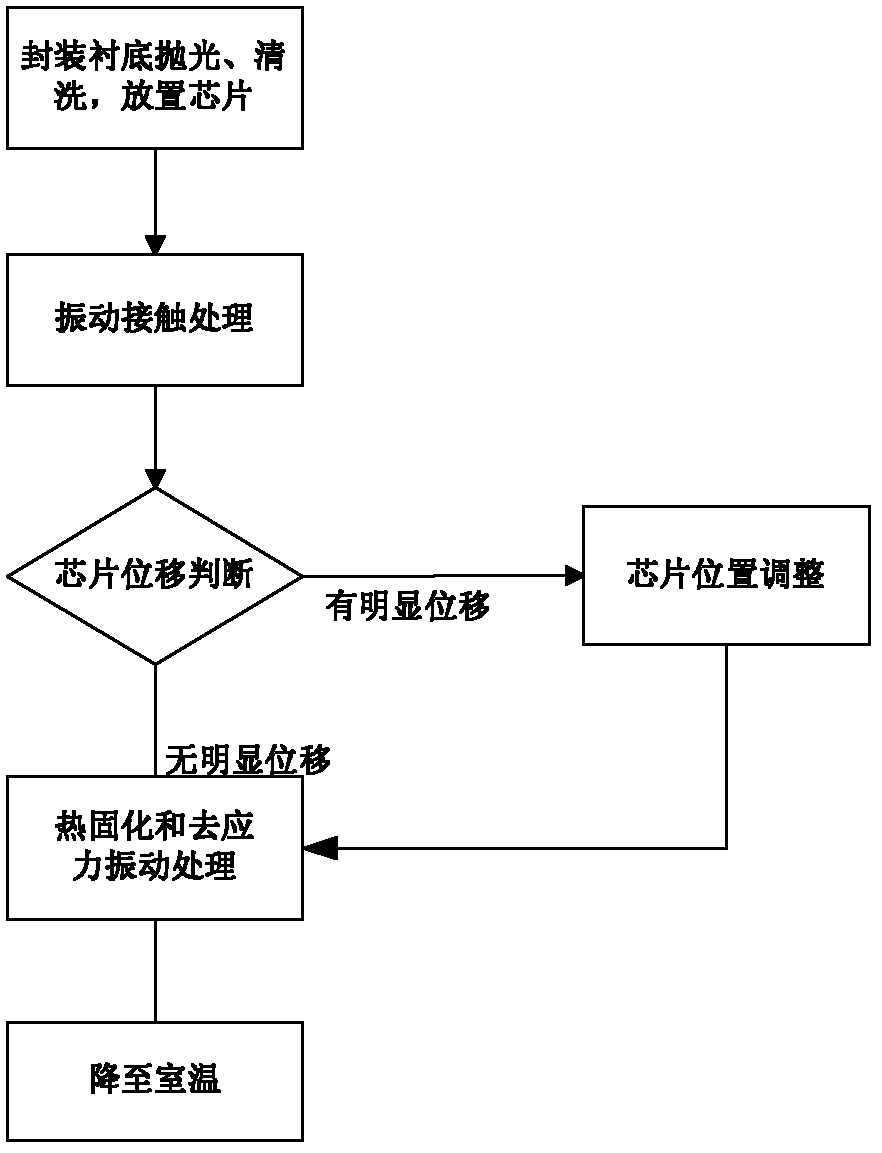

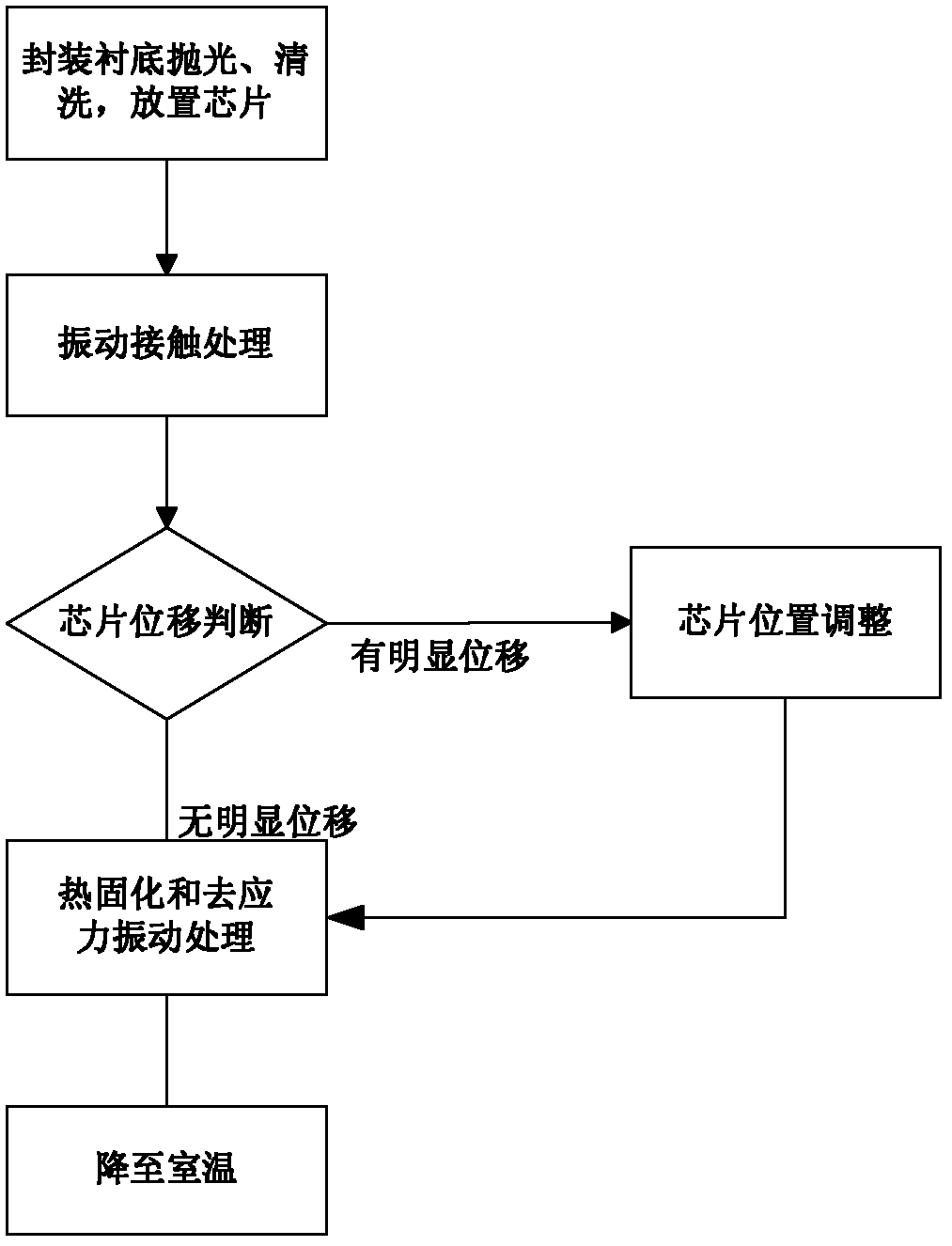

[0015] A chip packaging method based on epoxy resin adhesive, such as figure 1 , 2 shown, including the following steps:

[0016] Step 1: Apply epoxy resin adhesive on the chip mounting position on the polished and cleaned package substrate, place the chip to be packaged on the adhesive, and move the chip back and forth several times laterally to make the package substrate Keep a large contact area with the chip and the adhesive to form a chip-level packaging structure, and then fix the chip-level packaging structure on the vibration table.

[0017] Step 2: Adjust the vibration frequency and vibration amplitude of the vibration table, control the vibration time, and perform contact vibration treatment on the chip-level packaging structure in the plane normal direction of the chip-level packaging structure, so as to remove the epoxy resin adhesive and packaging as much as possible. Air bubbles that may exist between the substrate or chip, and maximize the contact area between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com