LED light spot improving method

A light spot and phosphor technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of fast product attenuation and large difference in light spots, and achieve the effect of increasing the light-emitting area, improving luminous flux, and avoiding large differences in light spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

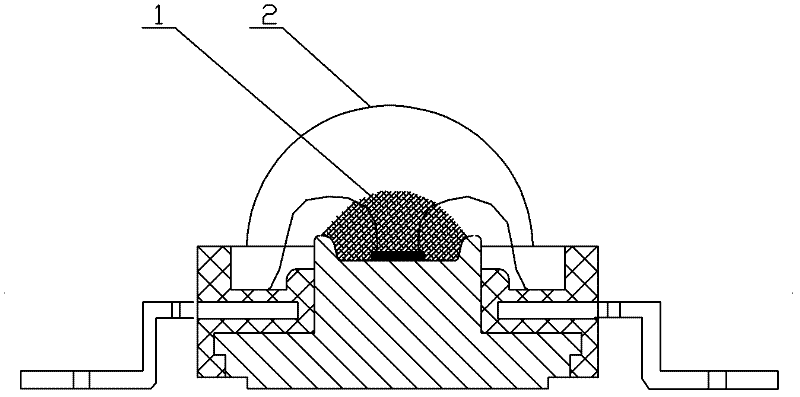

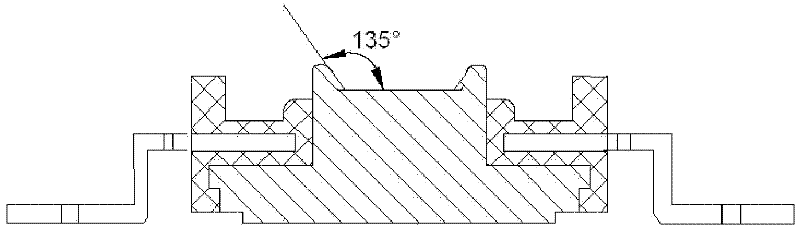

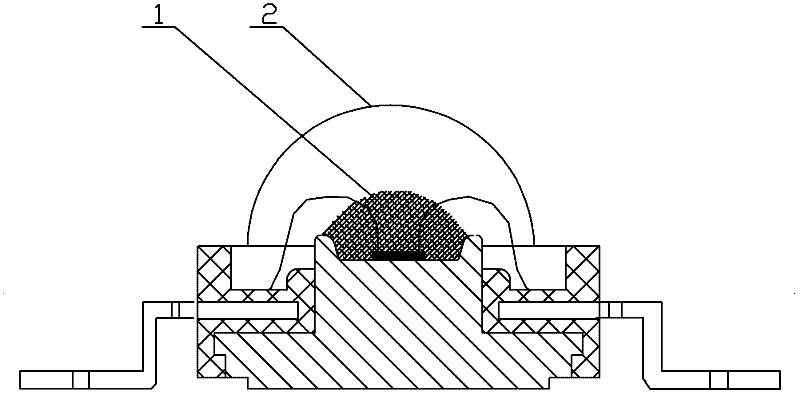

[0014] Please refer to Figures 1 to 2 As shown, in this embodiment, a method for improving LED light spots comprises the following steps:

[0015] a. Material selection: choose a bracket with a cup depth of 0.46±0.02mm and a cup mouth angle of 135 degrees, and choose phosphors with a particle size of 17-19um and a particle size of 4-5um to match each other;

[0016] b. Glue dispensing: use yellow fluorescent glue 1 to form a hemispherical structure, and form two surfaces approximately parallel to the lens 2.

[0017] The LED light spot improvement method effectively improves the luminous flux by selecting phosphor powders with a particle size of 17-19um and a particle diameter of 4-5um to match each other, and the phosphor powder with a particle size of 4-5um replaces the diffusing powder, avoiding the combination of different chemical properties of the three powders The problem of large differences in light spots and fast product attenuation is caused by the combination. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com