Heat radiator and electrode integrated heat radiating device and manufacturing method thereof

A technology for heat dissipation devices and radiators, applied in the direction of electric solid state devices, semiconductor devices, electrical components, etc., can solve the problems of high cost of LED lamps, achieve the effects of improving heat dissipation efficiency, simplifying production steps, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

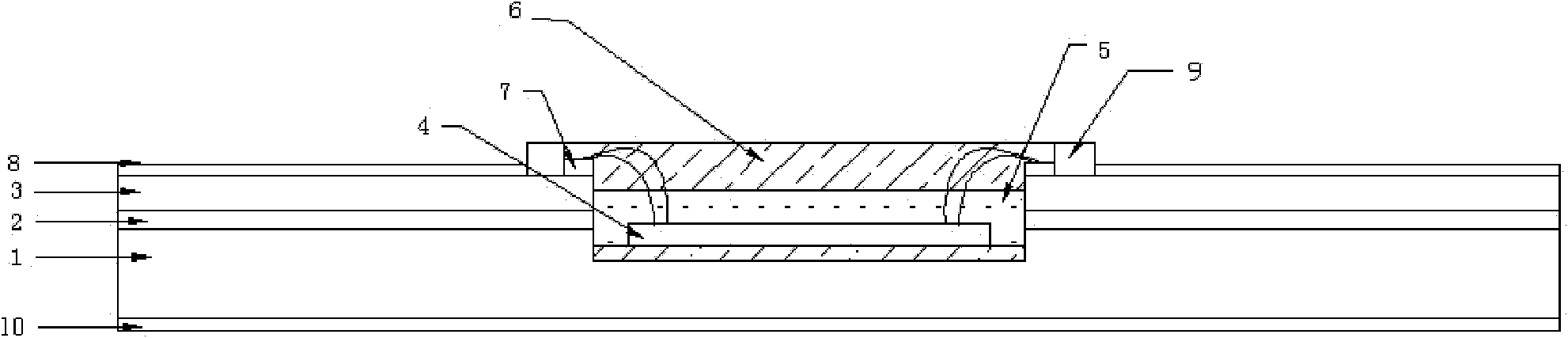

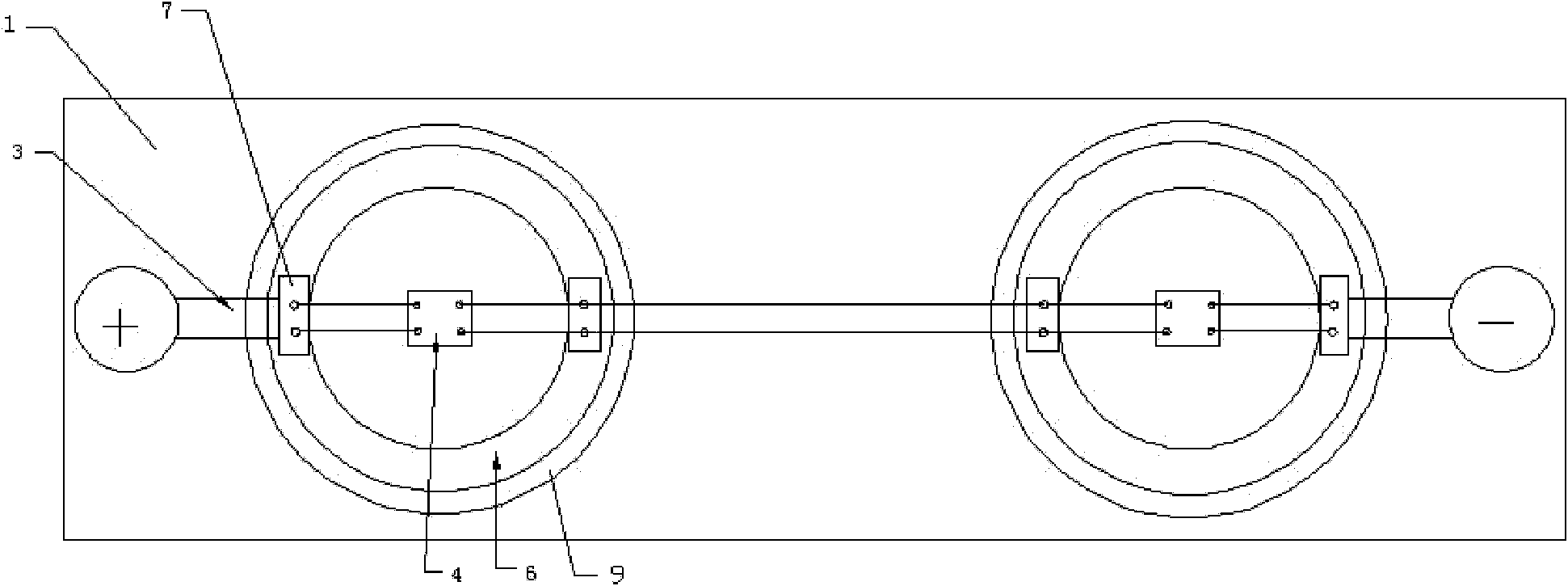

[0035] The preparation method of the heat dissipation device of the present invention comprises the following steps:

[0036] 1. The aluminum heat sink is cut and cleaned to obtain the heat dissipation substrate;

[0037] 2. Carry out hard anodic oxidation of aluminum on the heat dissipation substrate, and form an oxide layer on the heat dissipation substrate through oxidation, and the oxide layer achieves the purpose of insulating the heat dissipation substrate;

[0038] 3. Apply epoxy resin or epoxy glass cloth bonding sheet on the oxide layer, then attach copper foil, and heat-press the copper foil and the heat dissipation substrate as one, so that a layer of copper conductive layer is bonded to the oxide layer, or through Plating a layer of copper conductive layer on the oxide layer by evaporation or electroplating, and then etching away the parts that do not need circuit connection on the copper conductive layer according to the series or parallel connection required by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com