A composition for electron transport layer, electron transport layer and optoelectronic device

A technology of electron transport layer and optoelectronic device, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of easy aging of electronic materials, interface damage, fast brightness decay, etc., and achieve the improvement of luminous efficiency and life. Effects of reducing injection barrier and driving voltage and improving short lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

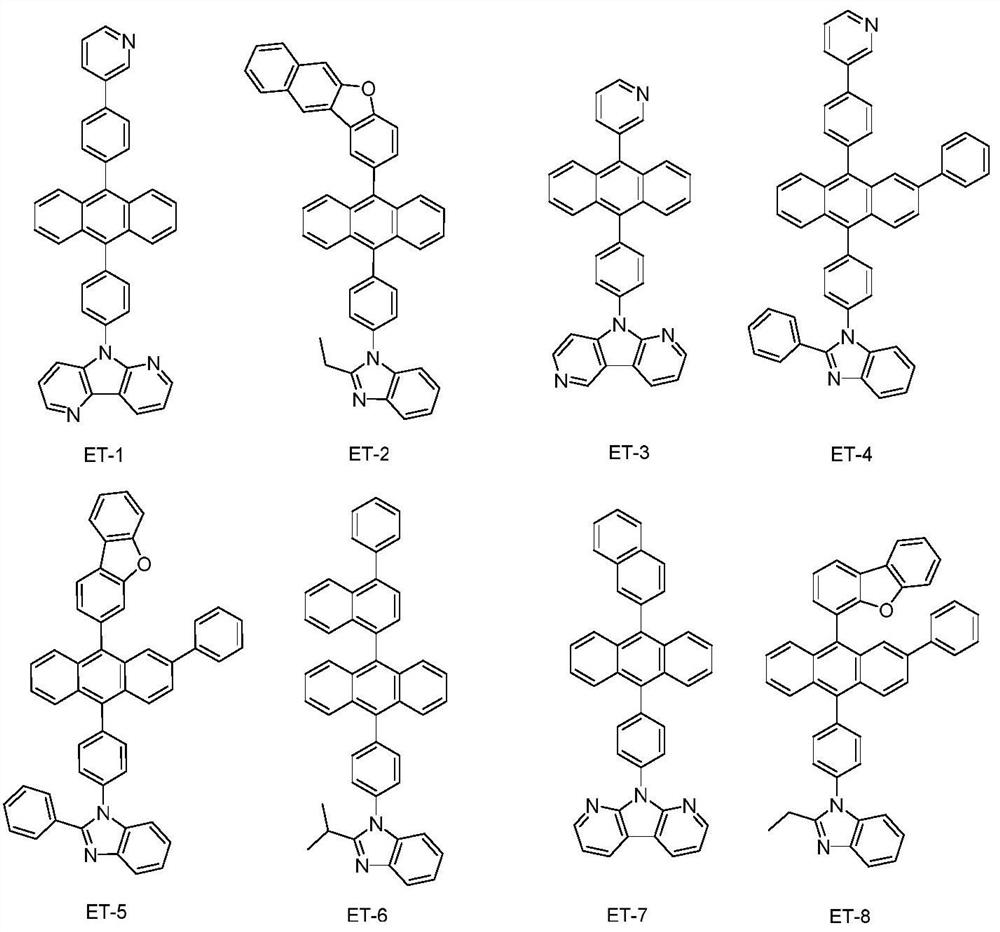

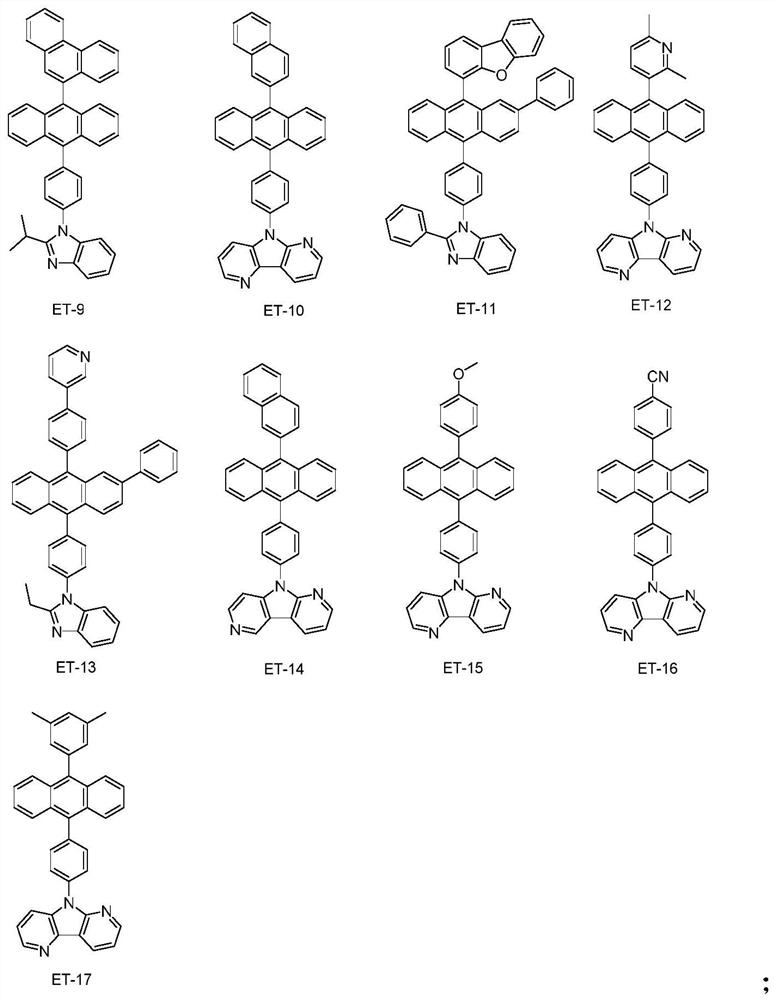

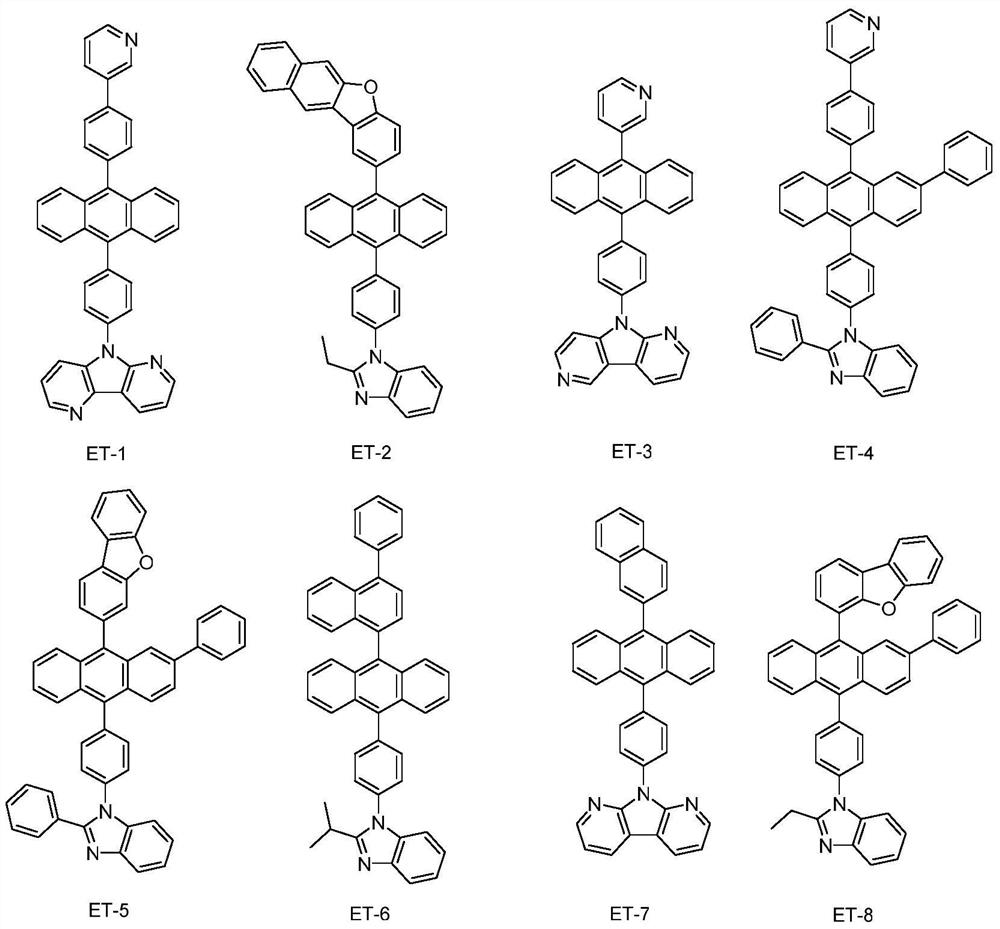

[0034] This example provides 17 kinds of electron transport materials, whose structural formulas are respectively formula ET-1 to formula ET-17, as shown below:

[0035]

[0036]

[0037] The electron mobility test is carried out on the electron transport materials whose structural formulas are respectively formula ET-1 to formula ET-17, and the test method is as follows:

[0038] Using vacuum evaporation equipment, vacuum evaporation is carried out on the substrate with ITO. Since the material to be tested is an electron transport material, a layer of electron blocking material with a thickness of 5nm is first evaporated. The test material and Liq, the thickness is 50nm, after the material to be tested is evaporated, the electron injection type material is evaporated, the thickness is 2nm, and finally a layer of cathode is evaporated, Ag can be used, and finally the SCLC space charge control current method is used to simulate Calculation, data collection of the material...

Embodiment 1

[0042] This embodiment provides an optoelectronic device, the preparation method of which includes the following steps:

[0043]S1. Clean the ITO / Ag / ITO film (ITO thickness is 14nm, Ag thickness is 150nm) on the glass substrate (150nm) of the OLED device in distilled water for 2 times, ultrasonically wash for 30 minutes, and repeatedly wash with distilled water for 2 times , ultrasonic cleaning for 10 minutes, after the distilled water cleaning is completed, isopropanol, acetone, methanol and other solvents are ultrasonically cleaned in sequence and then dried, transferred to the plasma cleaning machine, washed for 5 minutes, and sent to the evaporation machine.

[0044] S2. Compound N,N'-diphenyl-N,N'-bis(2-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB) with 2,3,5 , 6-tetrafluoro-7,7',8,8'-tetracyanoquinone-dimethane (F4-TCNQ) was introduced into the chamber of a vacuum vapor deposition apparatus at a doping ratio of 97:3, and the apparatus was then The pressure in the chamber i...

Embodiment 2

[0055] This embodiment provides an optoelectronic device, which is prepared according to the preparation method provided in the above device embodiment 1, the only difference is that the material ET-1 / ET-2 of the electron transport layer is replaced with the material in the material embodiment 1. ET-1 / ET-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com