Retract mandrel mill and method for rolling tubing

A seamless pipe rolling mill and mandrel-type technology, which is applied in the field of pipe rolling, can solve the problems of large speed difference of mandrel 11 and damage of mandrel 11, etc., and achieve the effect of suppressing loss and high yield

Inactive Publication Date: 2012-07-04

NIPPON STEEL CORP

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

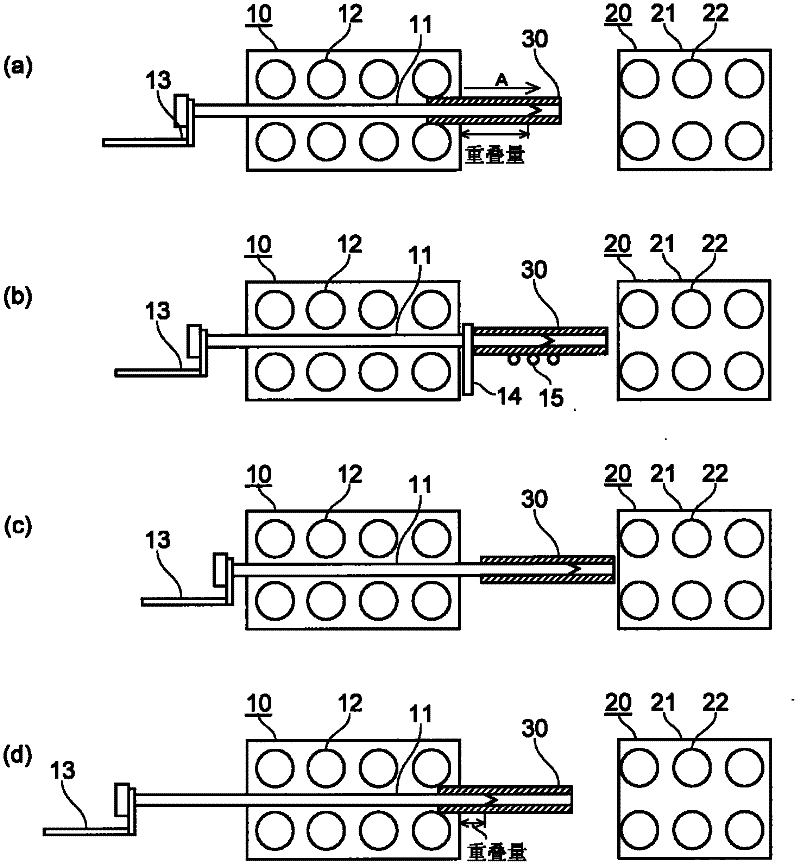

However, when the moving speed of the mandrel 11 is reduced, the speed difference between the mandrel 11 and the pipe material 30 becomes large, and friction with the pipe material 30 during the rolling process by the mandrel mill 10 occurs. The problem that the mandrel 11 is prone to damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0050] In order to confirm the effects of the present invention, a rolling test of a pipe material was performed as follows.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

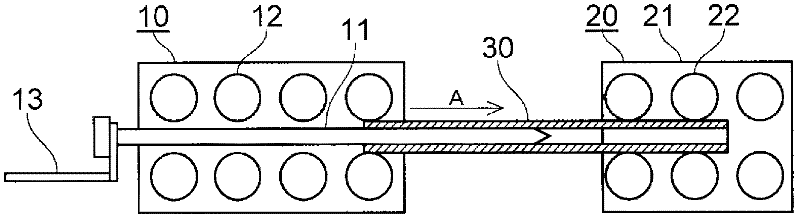

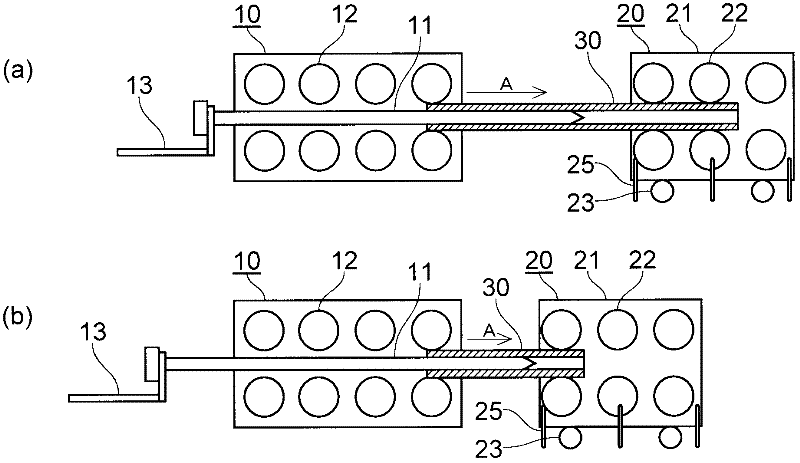

Disclosed are a retract mandrel mill and a method for rolling tubing using the mandrel mill. The retract mandrel mill is provided with a mandrel mill and an extractor. The mandrel mill includes a mandrel bar and is for rolling a tubing wherein the mandrel bar has been inserted. The extractor is for extracting the mandrel bar from the tubing which has been rolled by the mandrel mill. The distance between the mandrel mill and the extractor is adjustable, thus it is not necessary to increase the length of the tubing to be stretch rolled, even when rolling unusually short tubing, and wear to the mandrel bar can be limited, enabling efficient and good-yield rolling.

Description

technical field [0001] The present invention relates to a pull-back type mandrel mill for seamless pipes which does not need to lengthen the length of the pipe for elongation rolling unnecessarily and can suppress the loss of the mandrel when producing a product shorter than conventional ones. The present invention also relates to a method for rolling pipes using the pull-back mandrel mill for seamless pipes. Background technique [0002] In this specification, the pull-back type mandrel mill is an elongation rolling device including a mandrel mill and a puller. A sizing mill can also be used as the extractor. When a conventional drawing machine is used, the outer diameter of the pipe material drawn by the drawing machine is finished to a predetermined size using a reducing mill. In the case of using a sizing mill, the pipe material is pulled out by the sizing mill, and its outer diameter is finished to a predetermined size. [0003] Conventionally, when producing seamles...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21B17/04B21B19/10B21B23/00

CPCB21B19/10B21B23/00B21B17/04

Inventor 山根明仁

Owner NIPPON STEEL CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com