Stepping switch comprising vacuum switching tubes

A technology of vacuum switching tubes and tap changers, which is applied in the direction of electric switches, instruments, and adjustment of electric variables, etc. It can solve the problem that the structural space of the load transfer switch is no longer sufficient, and achieve the effect of a compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

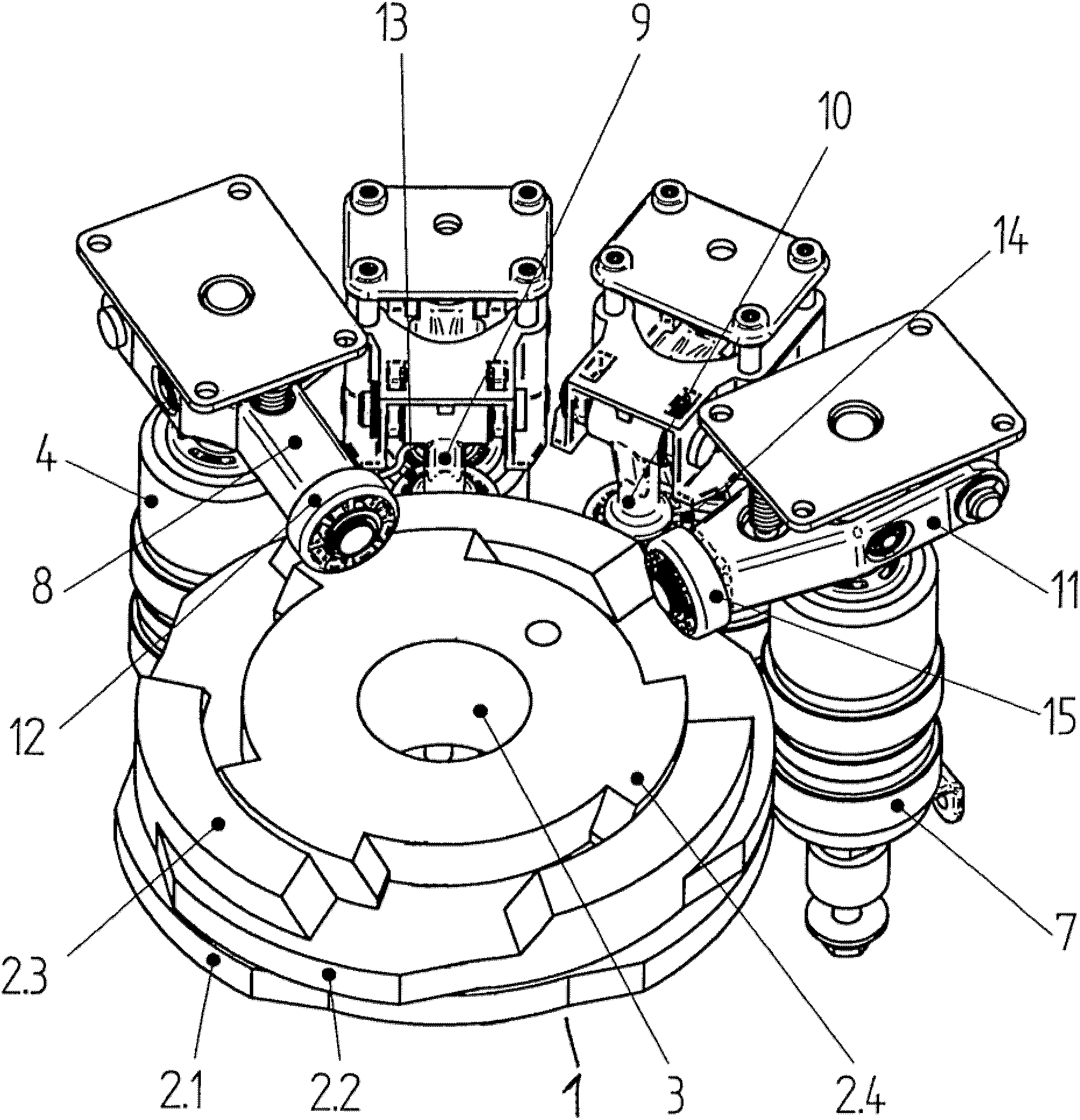

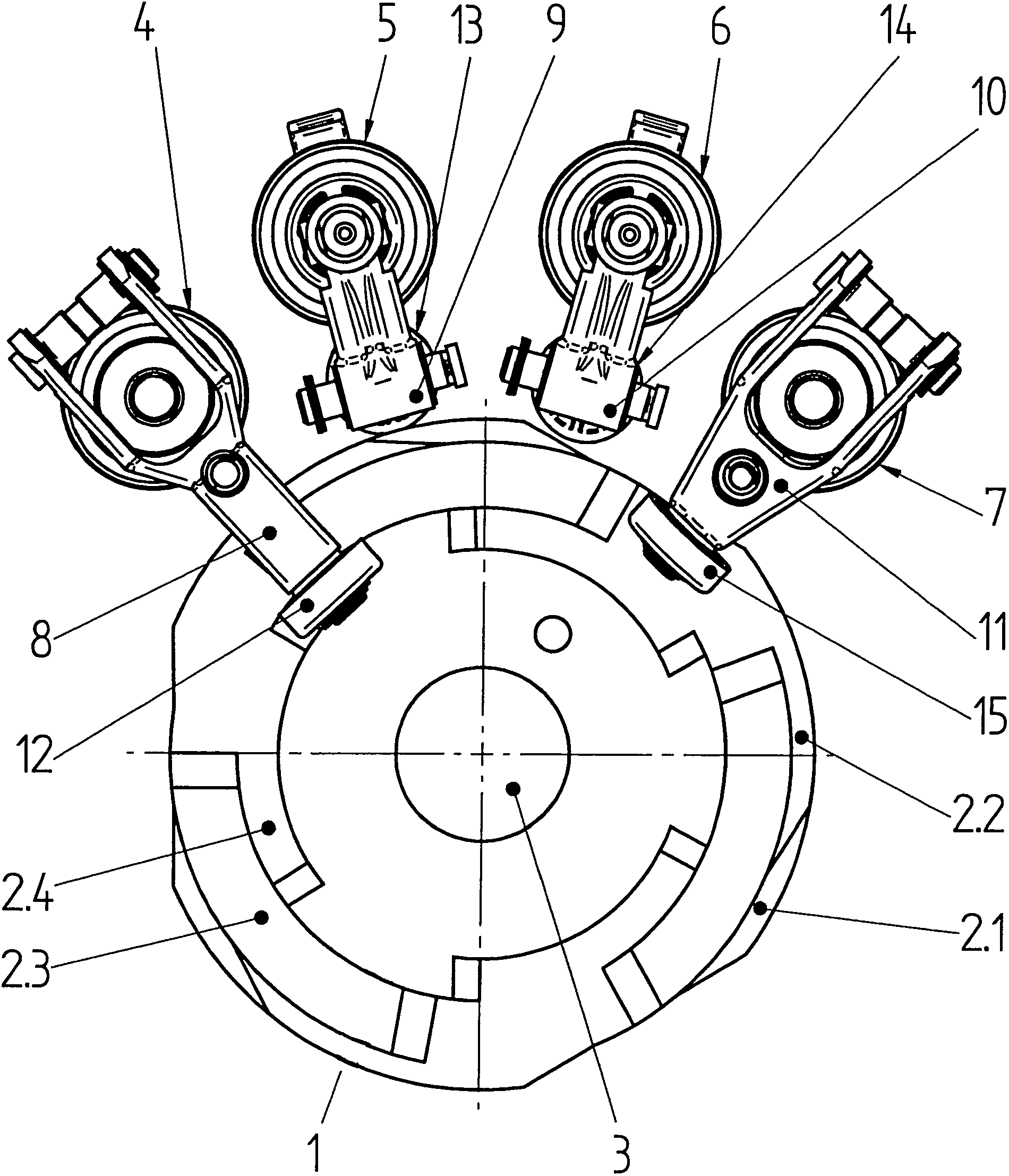

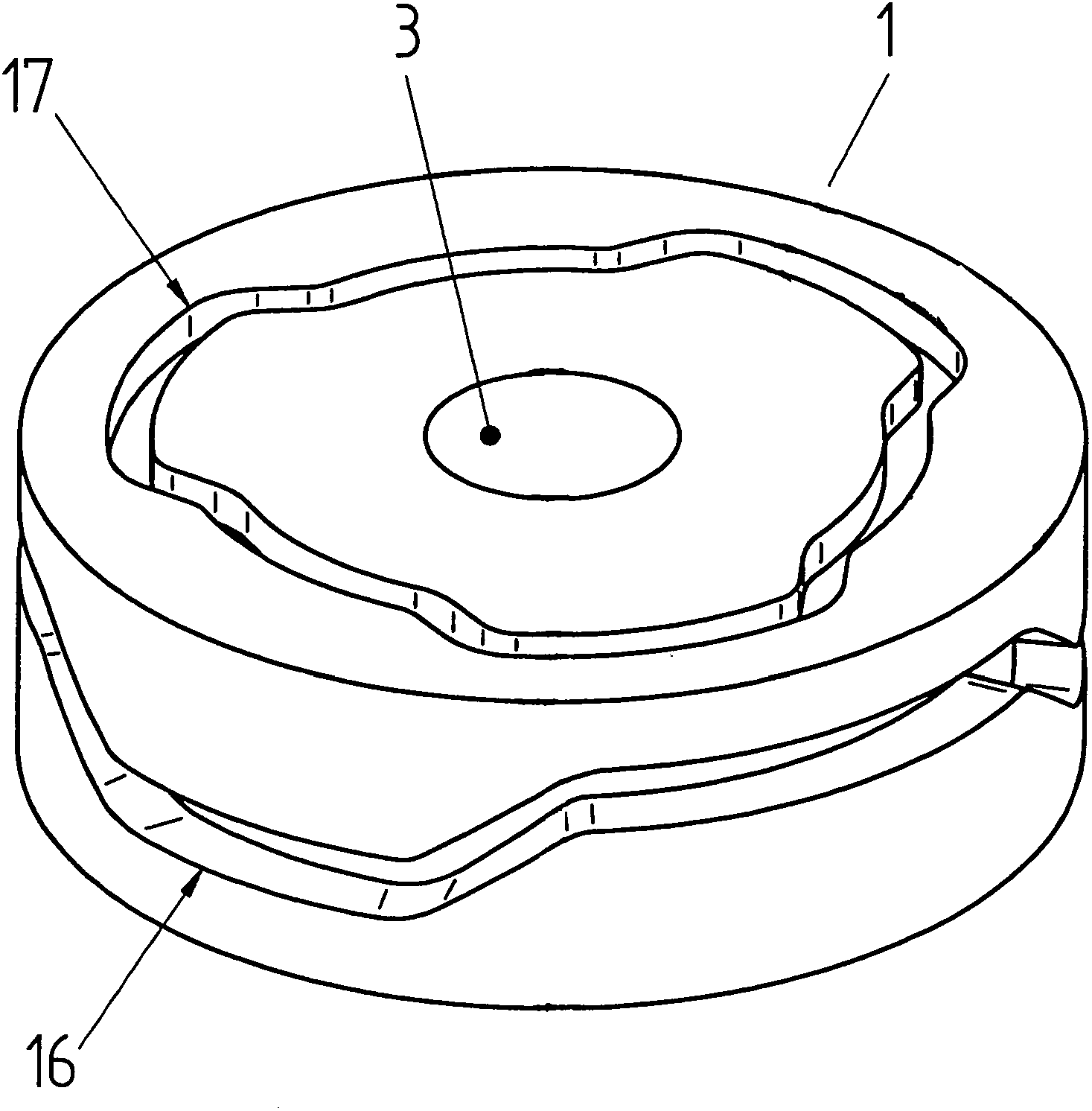

[0015] For clarity, the following is in figure 1 Only the important inventive parts of the tap changer including the vacuum interrupter according to the invention are shown and described in the text. Description and illustration of features known per se and components not essential to the essence of the invention are omitted. therefore, figure 1 An embodiment of a cam disc 1 is shown, which comprises a plurality of control cams 2.1, 2.2, 2.3 and 2.4, which in cooperation with them control the temporal switching process of the contact system for the changeover tap changer and Suitable for handling multiple vacuum interrupters. Two control cams 2 . The rods 9 and 10 are connected to the vacuum switching tubes, which are not visible in this view, said rollers engaging the profiled contours of the respective control cams 2.1 and 2.2. Since the rollers 13 and 14 are used here for engaging surface topography other than circular contours, they can also be replaced by other equall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com