Processing method of suit cuff

A processing method and technology for suits, applied in clothing, apparel, applications, etc., can solve the problems of unsmooth shape, rigid cuff lines, hard and soft hand feeling of the finished product, etc., and achieve the effect of crisp appearance, soft hand feeling, and improved grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

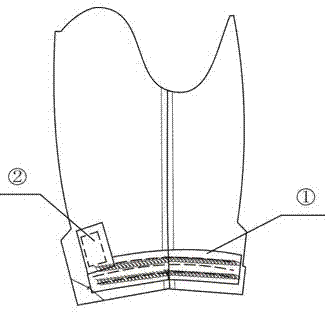

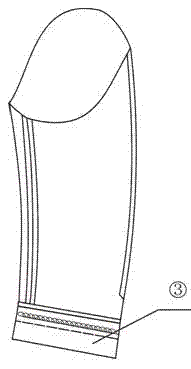

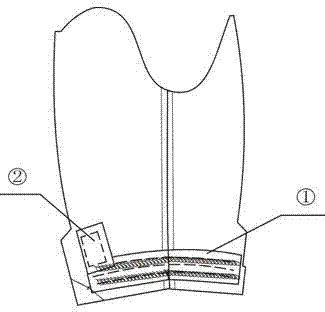

Image

Examples

Embodiment 1

[0024] In the above step 1) use 5cm wide black charcoal lining strips of straight diagonal silk; step 2) the cuff lining is 2cm away from the cuff, 0.2cm away from the small sleeve, 0.3cm away from the corner of the big sleeve, and make a 1.5cm cut on the inner seam of the sleeve ;Sleeve false eye lining and cuff lining overlap by 1cm; Step 4) Iron the cuff hem by 4cm; Step 6) Fix the cuff hem by prying 1.5cm away from the raw edge.

Embodiment 2

[0026] In the above step 1) use a 7cm wide black charcoal lining of positive bias silk; step 2) the cuff lining is 1cm away from the cuff, 0.3cm away from the small cuff, and 0.4cm away from the corner of the big cuff, and cut 2.5cm at the inner seam of the sleeve ;Sleeve false eye lining and cuff lining overlap by 2cm; Step 4) Iron the cuff hem by 5cm; Step 6) Fix the cuff hem by prying 0.7cm away from the raw edge.

[0027] Process standard:

[0028] The sewing is standard, the position of the carbon lining is accurate, and the cuffs are smooth, full and flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com