Method for coating magnesium oxide on surfaces of grain-oriented silicon steel strips

A technology of oriented silicon steel and a coating method, which is applied to the device and coating of the surface coating liquid, can solve the problems of unevenness and unevenness of magnesium oxide, and achieve the effects of high product quality, stable spraying, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The following process technology and structural parameters are adopted:

[0029] 1. The width of the oriented silicon steel strip coated with magnesium oxide is 650mm;

[0030] 2. The viscosity (25°C) of the coated magnesium oxide is 11s;

[0031] 3. The quality of magnesium oxide used is heavy magnesium oxide;

[0032] 4. The belt speed is 15m / min;

[0033] 5. The coating amount of magnesium oxide is 6g / m 2 ;

[0034] 6. The material of the liquid supply nozzle is 1Cr18Ni9;

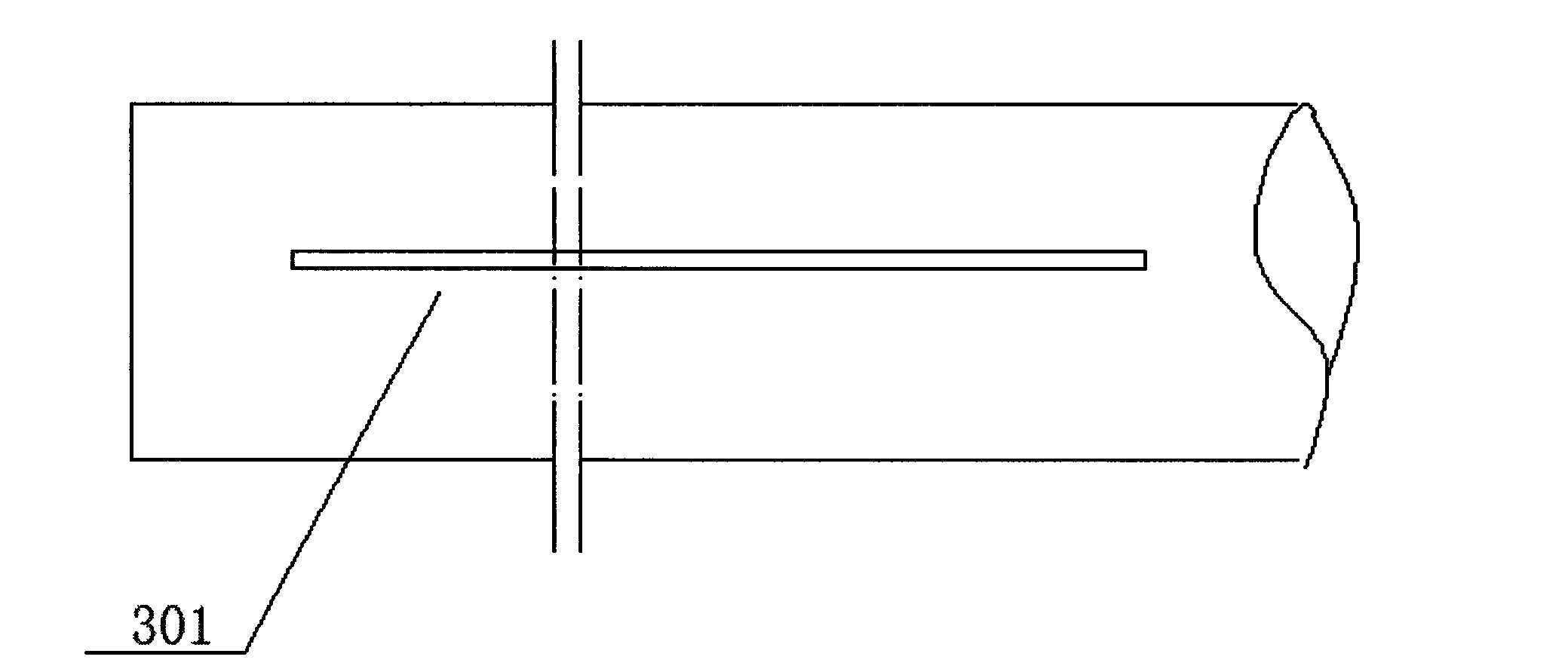

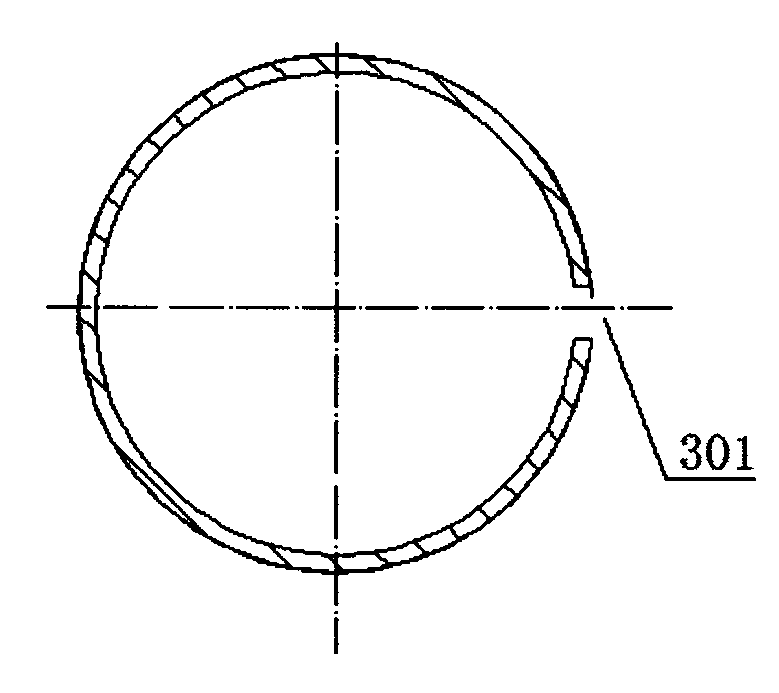

[0035] 7. The specification of the stainless steel cold drawn nozzle is ¢60×2.0mm;

[0036] 8. A long slit is set on the stainless steel cold drawn nozzle.

[0037] 9. The length of the long slot is 150mm wider than the width of the grain-oriented silicon steel strip coated with magnesium oxide.

[0038] 10. The seam width of the long seam is 2.5mm.

Embodiment 2

[0040] The following process technology and structural parameters are adopted:

[0041] 1. The width of the oriented silicon steel strip coated with magnesium oxide is 600mm;

[0042] 2. The viscosity (25°C) of the coated magnesium oxide is 12s;

[0043] 3. The quality of magnesium oxide used is heavy magnesium oxide;

[0044] 4. The belt speed is 25m / min;

[0045] 5. The coating amount of magnesium oxide is 8g / m 2 ;

[0046] 6. The material of the liquid supply nozzle is 1Cr17Ni9;

[0047] 7. The specification of the stainless steel cold drawn nozzle is ¢60×2.0mm;

[0048] 8. A long slit is set on the stainless steel cold drawn nozzle.

[0049] 9. The length of the long slot is 200mm wider than the width of the grain-oriented silicon steel strip coated with magnesium oxide.

[0050] 10. The seam width of the long seam is 2.8mm.

Embodiment 3

[0052] The following process technology and structural parameters are adopted:

[0053] 1. The width of the oriented silicon steel strip coated with magnesium oxide is 620mm;

[0054] 2. The viscosity (25°C) of the coated magnesium oxide is 10s;

[0055] 3. The quality of magnesium oxide used is heavy magnesium oxide;

[0056] 4. The belt speed is 20m / min;

[0057] 5. The coating amount of magnesium oxide is 5g / m 2 ;

[0058] 6. The material of the liquid supply nozzle is 1Cr18Ni9;

[0059] 7. The specification of the stainless steel cold drawn nozzle is ¢60×2.0mm;

[0060] 8. A long slit is set on the stainless steel cold drawn nozzle.

[0061] 9. The length of the long slot is 180mm wider than the width of the grain-oriented silicon steel strip coated with magnesium oxide.

[0062] 10. The seam width of the long seam is 3.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com