Oil immersing and drying device for workpieces

An air-drying device and oil-immersed technology, which is applied to the surface coating liquid device, pre-treated surface, coating, etc., can solve the problems of reduced life, easy damage, easy rust, etc., and achieves good results and short air-drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

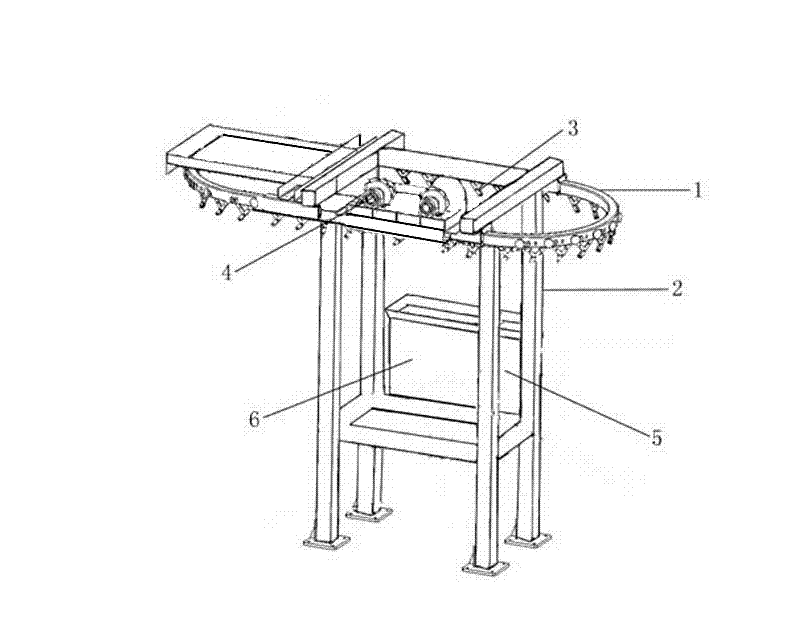

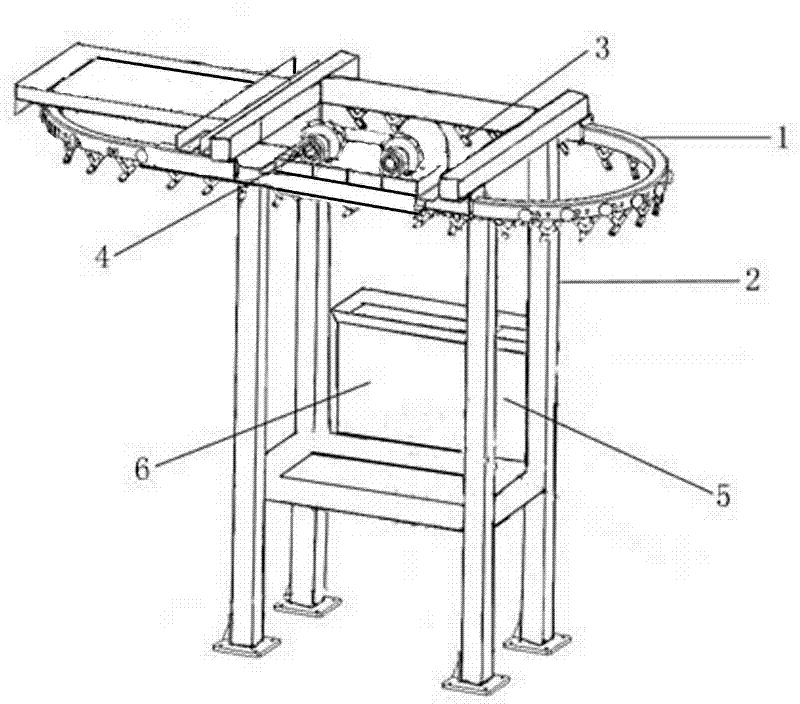

[0008] In order to further disclose the technical solution of the present invention, the implementation mode of the present invention will be described in detail in conjunction with the accompanying drawings: figure 1 As shown, a workpiece oil-immersed air-drying device includes two parts, an upper bracket 1 and a lower bracket 2, the upper bracket 1 is provided with a hook 3 and a wheel 4, and one side of the lower bracket 2 is provided with an oil immersion tank 5 With the air-drying box 6, the two boxes are arranged left and right, and are closely connected to form a whole. Described oil immersion tank 5 and air-drying tank 6 bottom are provided with air cylinder, can make casing move up and down.

[0009] When the device is in use, the workpiece is hung on the hook, and the workpiece first enters the oil immersion tank. After a period of time, the oil immersion tank moves down through the cylinder, and the workpiece moves forward to the air drying box through the wheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com