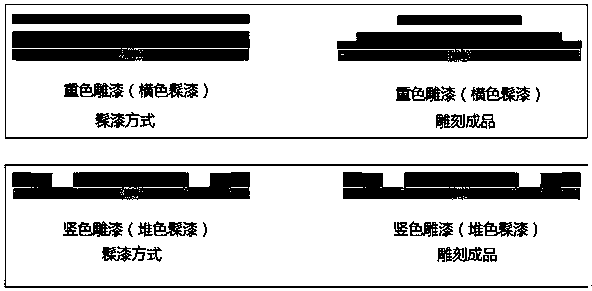

Production technology of vertical color carved lacquerware

A production process and technology of raw lacquer, which is applied in the production process of vertical-color carved lacquer, can solve the problems of labor and materials for carved lacquer works, no successors for practitioners, and long drying time of raw lacquer, so as to save raw materials, short drying time, and relief Expressive Accurate and Lifelike Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A production process of vertical color carved lacquer to produce wood embryo flower and bird picture carved lacquer works, including the following production process:

[0036] 1. Refined lacquer

[0037] 1) Selection of raw materials

[0038] Choose raw lacquer raw materials produced in Pingli County, Ankang City, Shaanxi Province. The raw lacquer produced in this area has a sour and fragrant taste, golden or red yellow color, thin and bleached lacquer liquid, good transparency, strong dryness, and a long storage period;

[0039] 2), filter processing

[0040] The above-mentioned raw lacquer raw materials are filtered by twisting and filtering. When filtering, take a piece of rectangular cloth, put the raw lacquer in the center of the cloth, and then fold the two long sides of the cloth several times in opposite directions to make a circle. Tubular shape, then fold the two ends tightly so that the paint does not flow out, and then put it on a wooden gallows for twisti...

Embodiment 2

[0058] A kind of production process of vertical color carved lacquer to produce carved lacquer works of copper embryo high mountains and flowing water, the production process is as follows:

[0059] 1. Raw lacquer refining

[0060] 1) Selection of raw materials

[0061] Choose raw lacquer raw materials produced in Pingli County, Ankang City, Shaanxi Province. The raw lacquer produced in this area has a sour and fragrant taste, golden or red yellow color, thin and bleached lacquer liquid, good transparency, strong dryness, and a long storage period;

[0062] 2), the above-mentioned paint liquid raw materials are filtered with a bag filter of 100 microns;

[0063] 3), low temperature stirring dehydration treatment

[0064] Put the filtered raw lacquer raw materials in a stirring plate, add a certain amount of water, and continuously stir, so that urushiol is oxidized into urushiol quinone under the catalysis of laccase, and then polymerized into urushiol dimer , trimer, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com