Calibration method for roller gaps of rolling machine

A calibration method and rolling mill technology, applied in the direction of rolling force/roll gap control, metal rolling, metal rolling, etc., can solve problems such as not meeting the process requirements of certain products, and achieve calibration time saving and roll gap calibration accuracy Accuracy, the effect of improving production efficiency and operation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

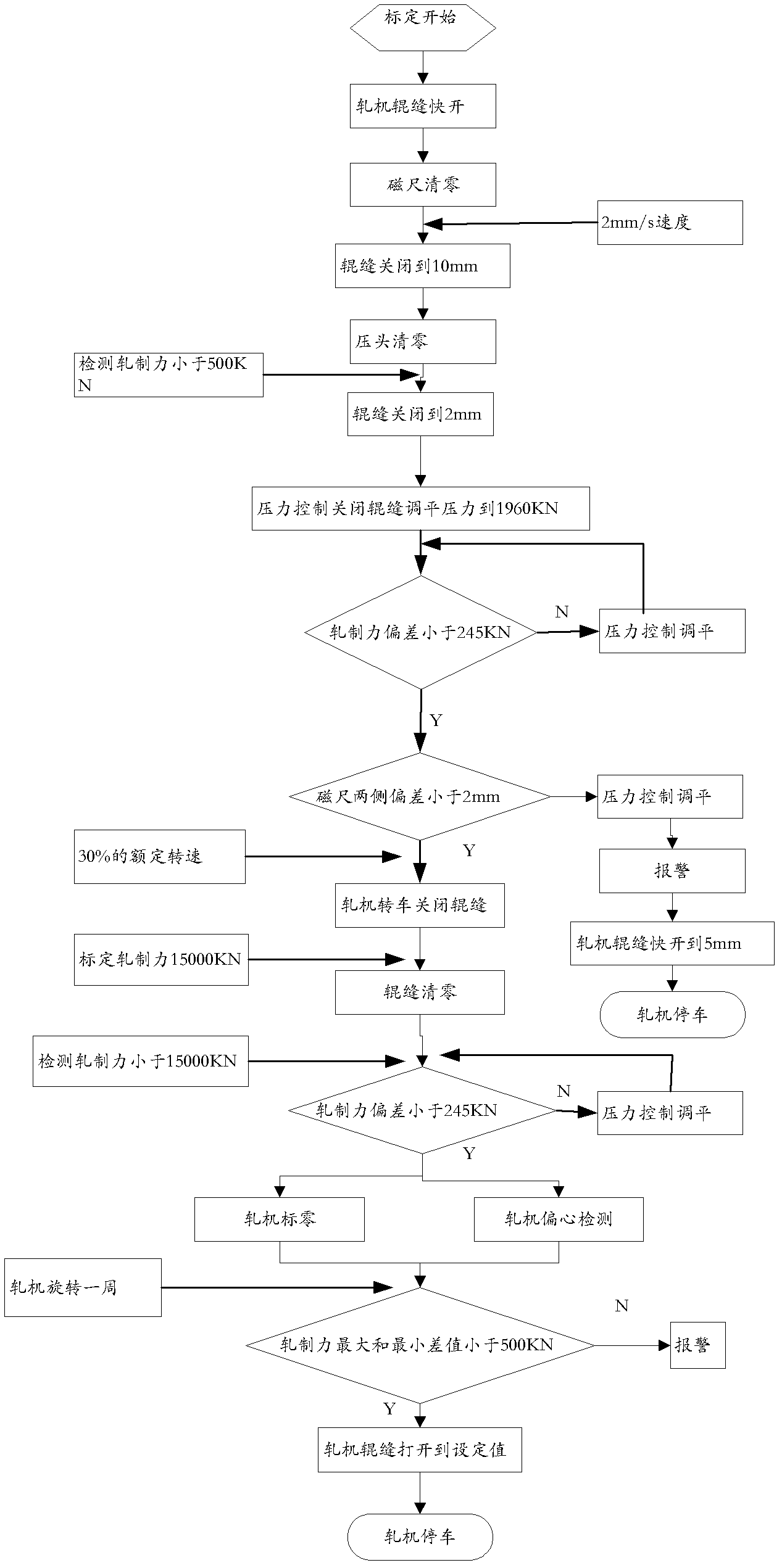

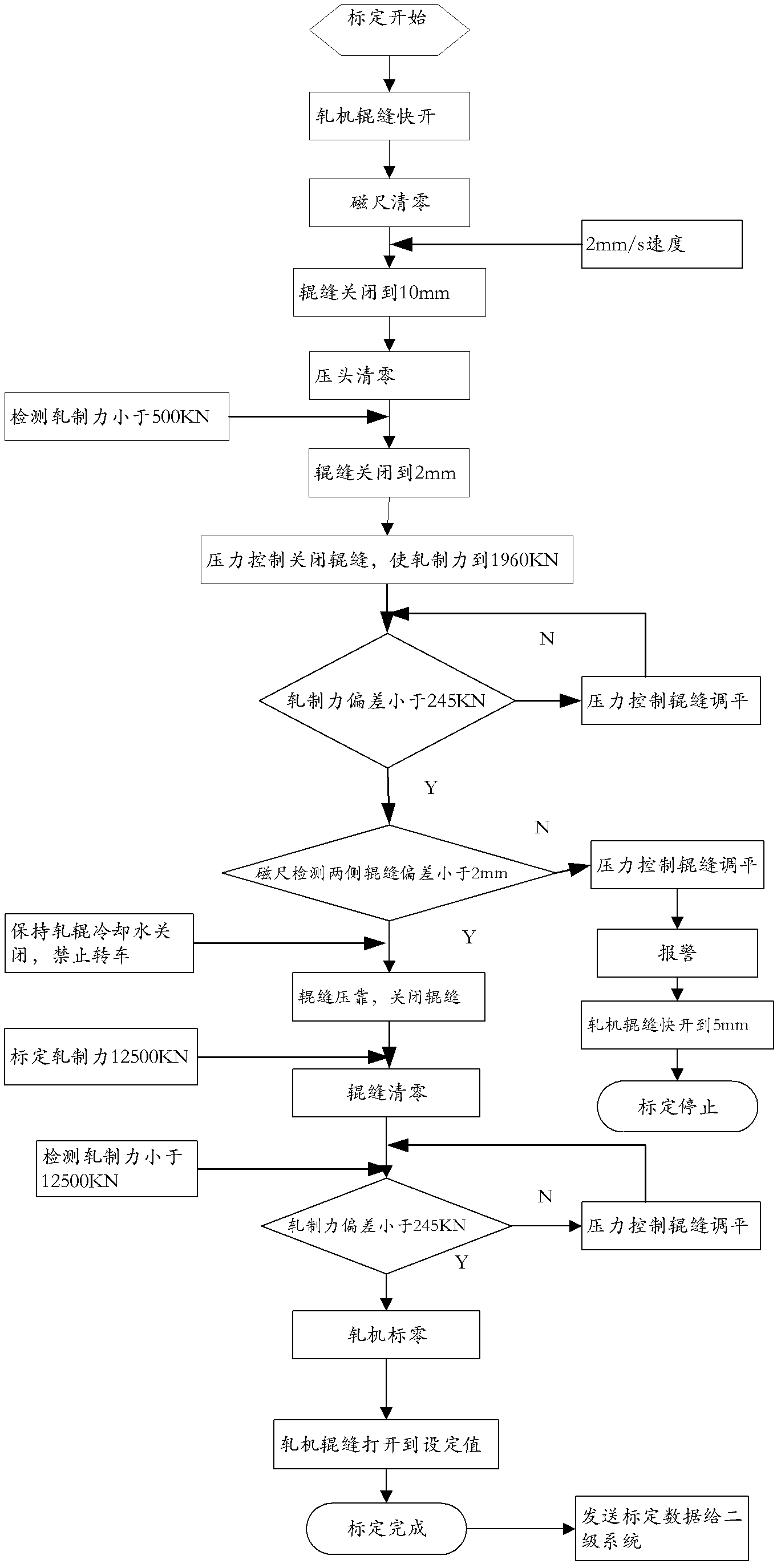

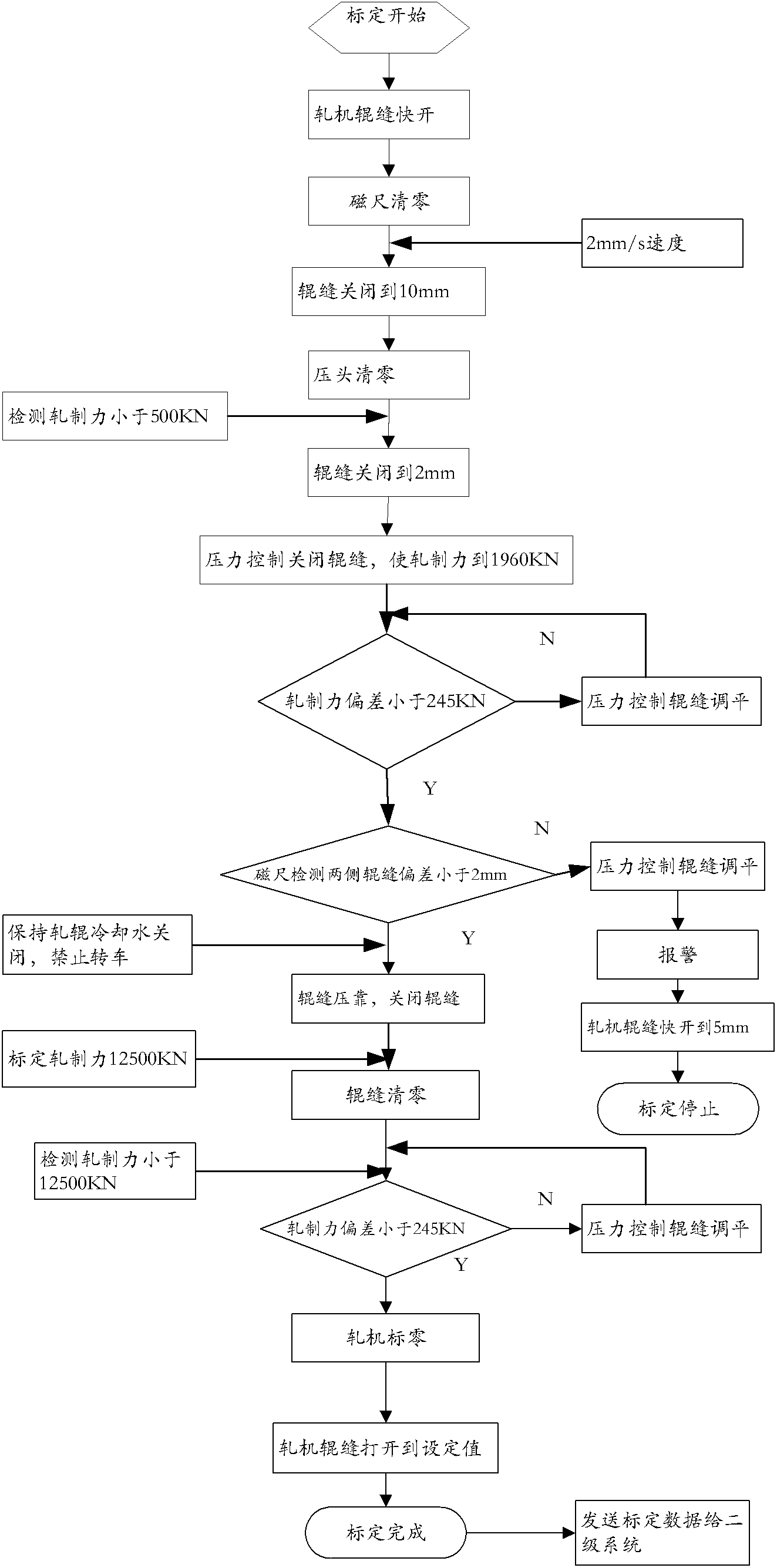

[0028] combine figure 1 , figure 2 As shown, the calibration method of a rolling mill roll gap provided by the present invention is implemented by a primary control system composed of PLC and other equipment, and includes the following steps:

[0029] Step S1: After clearing the magnetic ruler and pressure head of the AGC hydraulic cylinder of the rolling mill, perform pressure control roll gap leveling, and check the roll gap deviation on both sides of the operating side and the transmission side of the rolling mill.

[0030] Step S2: When the roll gap deviation on both sides of the operating side and the driving side of the rolling mill is normal, cancel figure 1 The steps of turning the middle rolling mill at a speed of 30% are prohibited, the roll gap is closed, the rolling force of the rolling mill is calibrated, and the roll gap is cleared.

[0031] Step S3: After the roll gap is cleared, check whether the sum of the rolling force on the operating side and the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com