Multistation feeding device of punching machine

A feeding device and multi-station technology, which is applied to the multi-station feeding device of a punching machine and the field of feeding devices, can solve the problems of manual operation that is prone to safety hazards, increase production costs, and difficulty in popularization and promotion, and achieve long-term use of equipment , saving manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

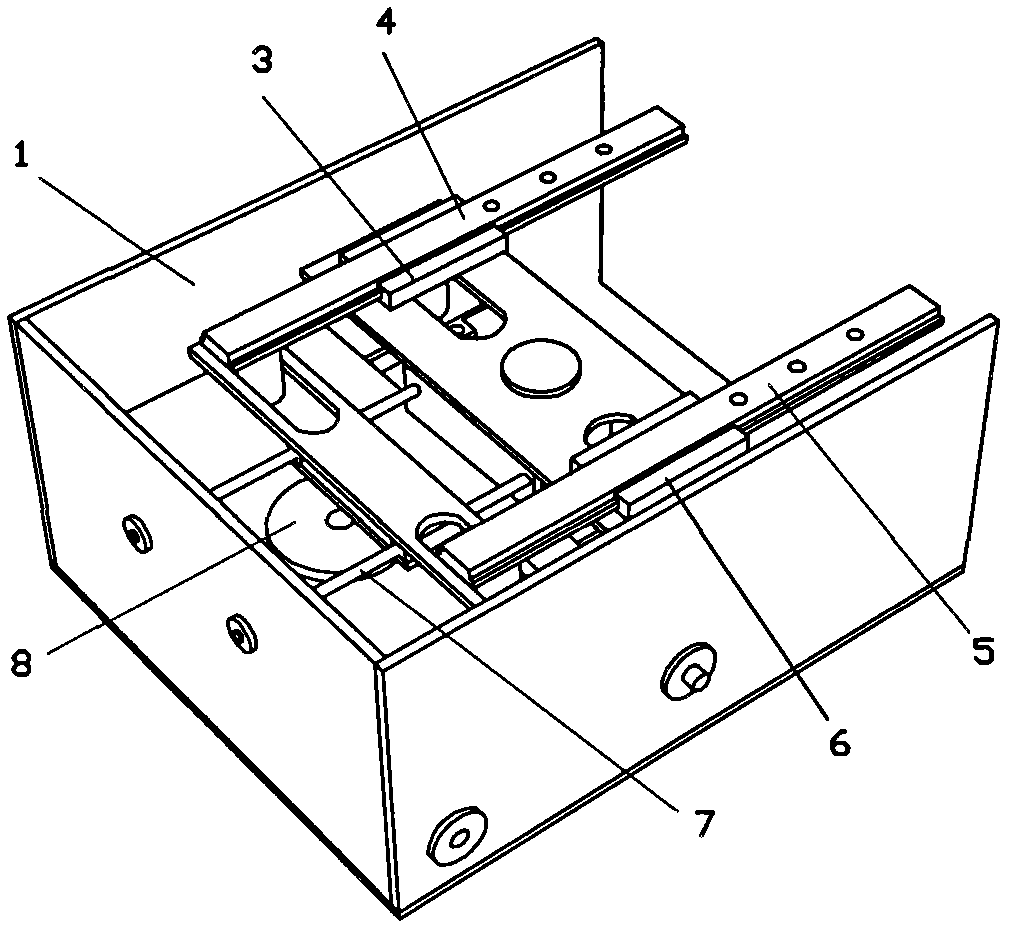

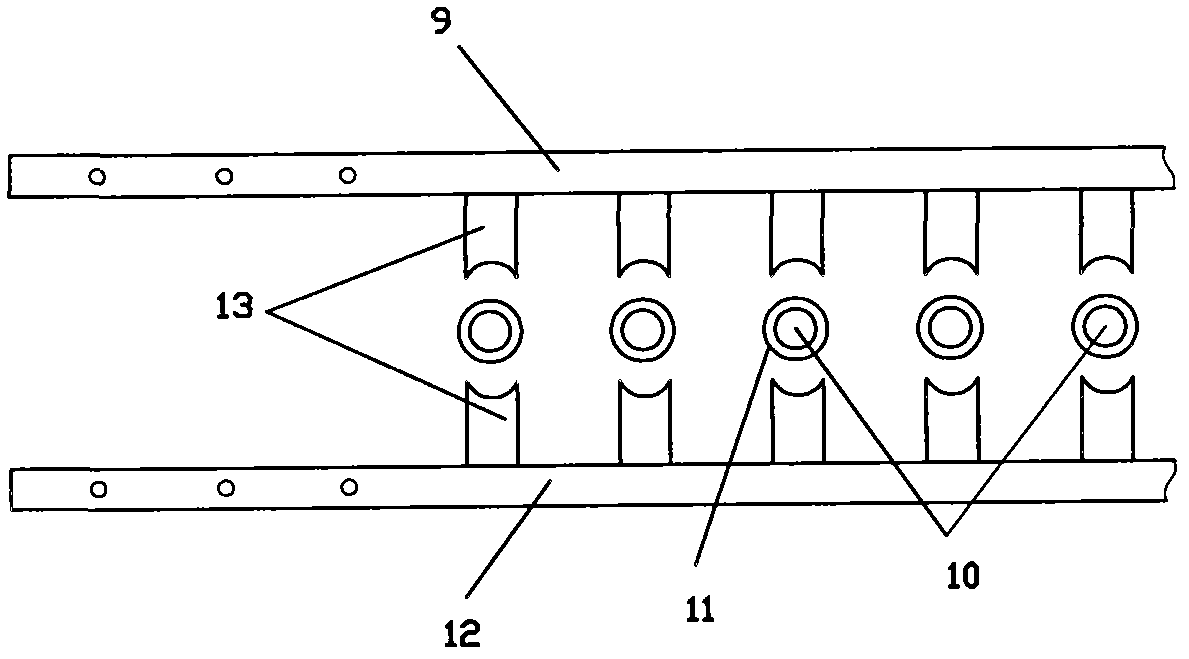

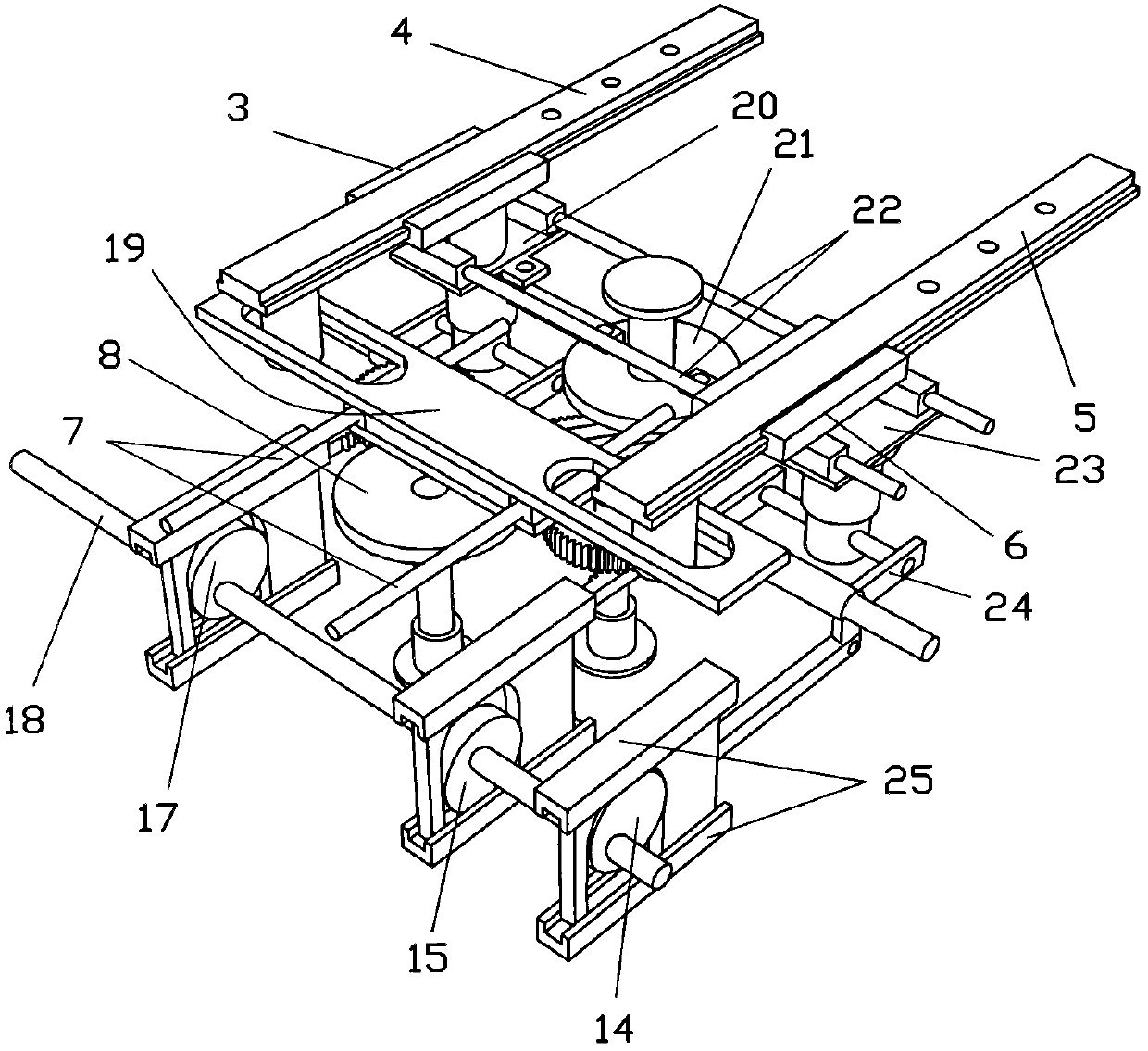

[0026] like Figure 1 to Figure 4 As shown, the present invention includes a bracket 1 connected to the work table of the punch press, the support 1 can be a steel plate structure, the main part is arranged on the left side of the work table of the punch press, and the lower part corresponding to the position of the stamping head of the punch press is provided on the support. There are two feeding arms 9, 12, and the two feeding arms 9, 12 are respectively provided with a set of feeding claws 13 for clamping the stamping part 10. When the workpiece is punched, the middle part of the working table between the feeding arms 9, 12 should be arranged side by side. The lower mold 11 of a set of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap