High-speed coiling roller device of amorphous thin strip

A take-up roll, amorphous technology, applied in the field of high-speed take-up roll device of amorphous thin strip, can solve the problems of coiling and adsorption capacity affecting the efficiency of coiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

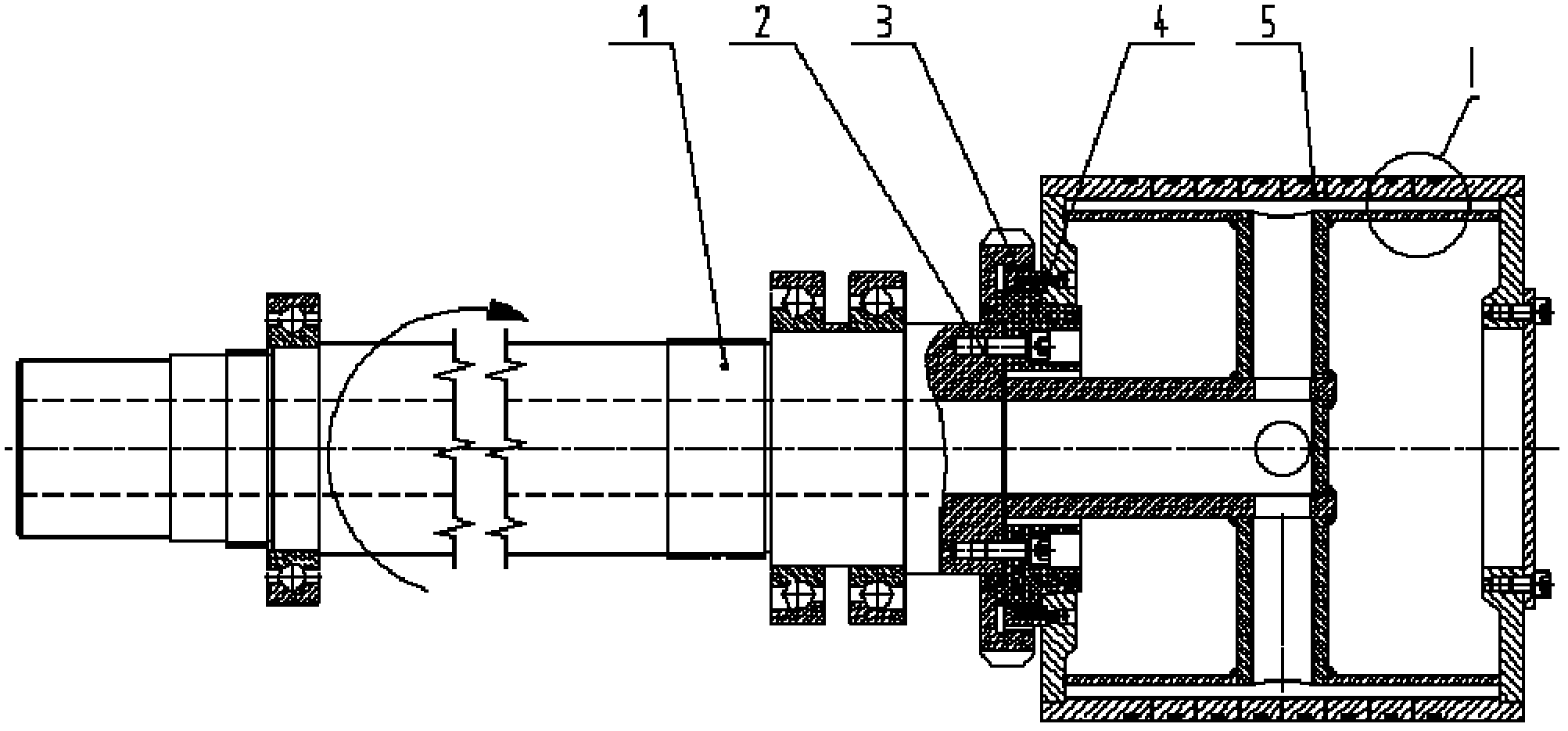

[0014] figure 1 It is a schematic diagram of the assembly structure of the present invention. The reel (1) has an inner hollow structure, and the reel (1) is supported on the bearing seat by the rolling bearings at both ends. The right end of the reel (1) forms a reel assembly through the bolt and the cone (4), and the take-up roller (5) left The side inner conical surface cooperates with the outer conical surface of the conical disc (4), and is pressed on the conical disc (4) by the lock nut (3), so as to realize the fast loading and unloading and centering functions of the coiling roller. The reel inner tube (13) on the take-up roller (5) compresses the sealing rubber pad (2) on the right end of the spool (1), forming a connected cavity.

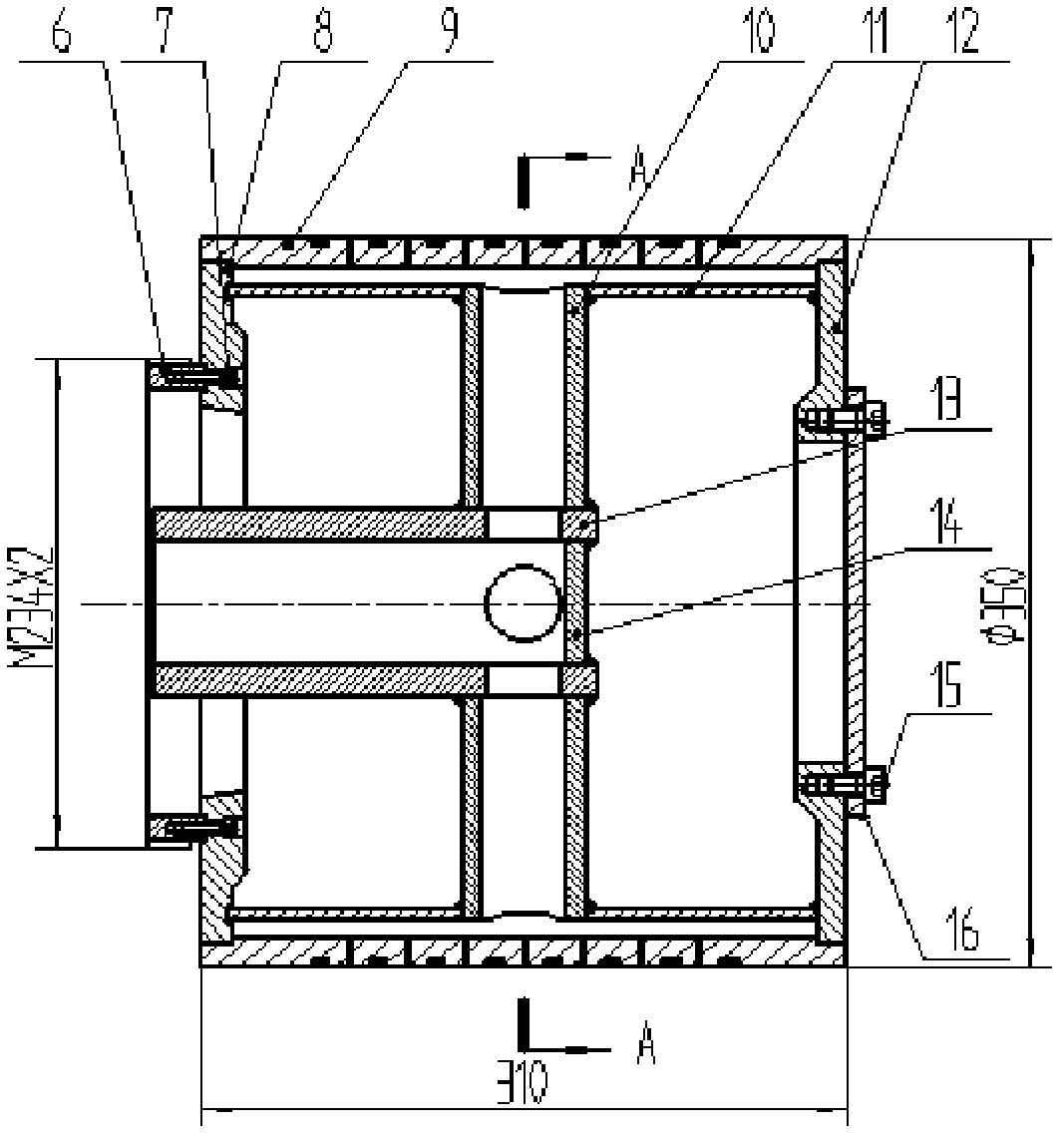

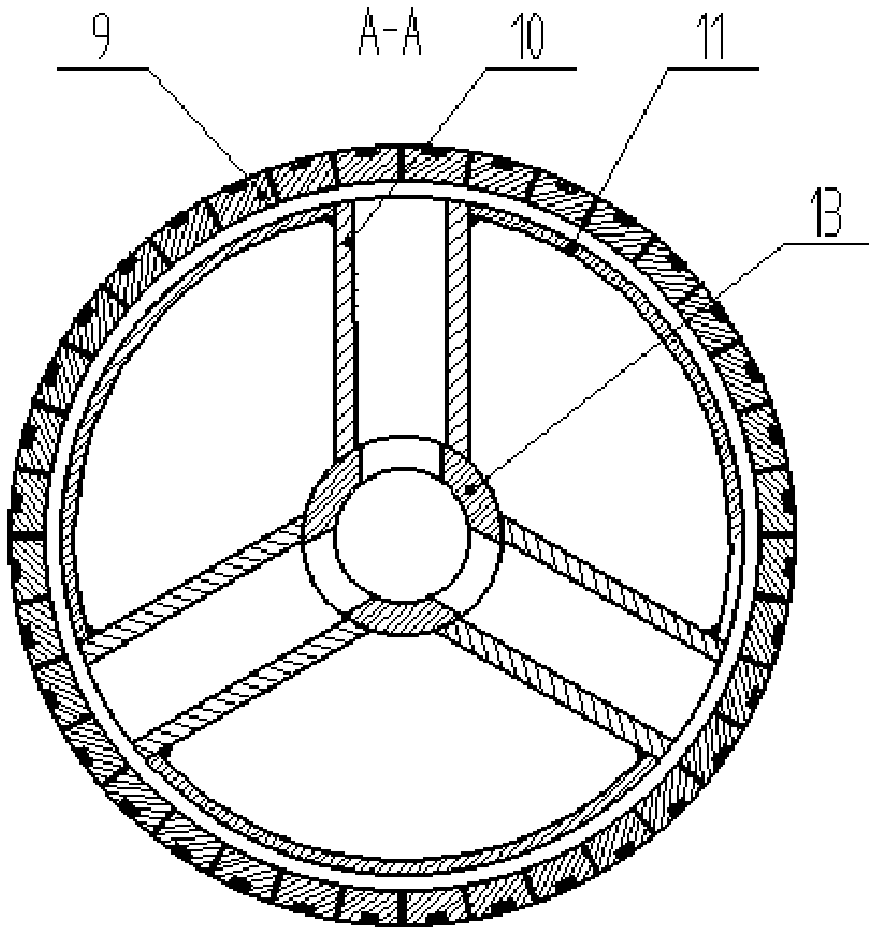

[0015] figure 2 , image 3 , Figure 5 It is the structural diagram of the take-up roller. The reel spiral ring (6) is fixed on the reel left end cover (8) by the hexagon socket bolt (7). The reel inner tube (13) is welded into a wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com