Volume-adjustable multi-mould quantitative pouring trough

A quantitative pouring and adjustable technology, applied in the field of pouring troughs, can solve the problems affecting the quantitative requirements of products, errors, and products that do not meet the quantitative requirements, and achieve the effect of improving production efficiency and product quality, low cost, and novel mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

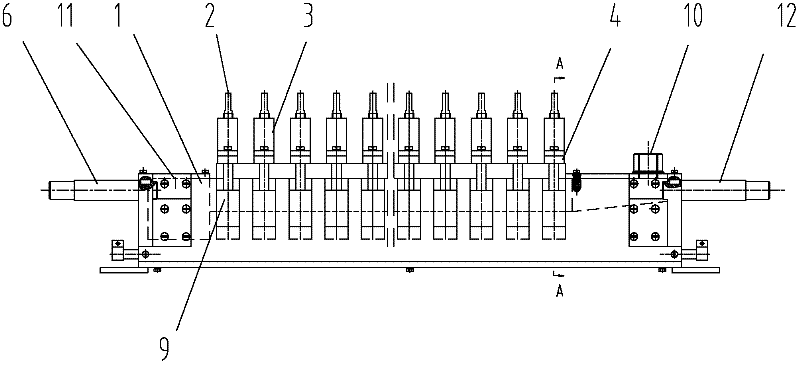

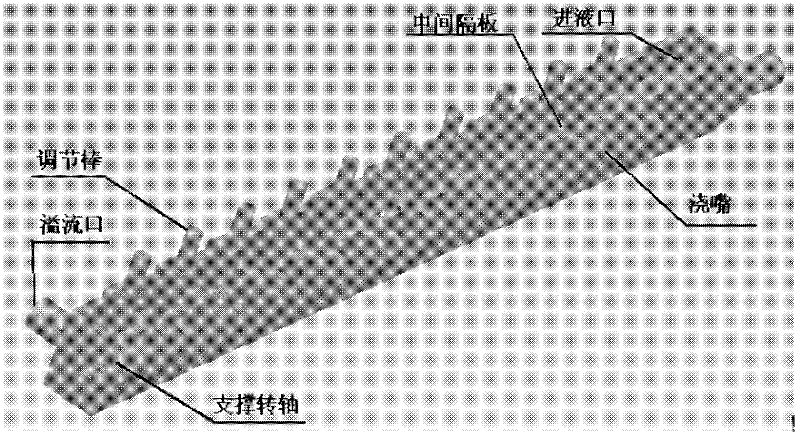

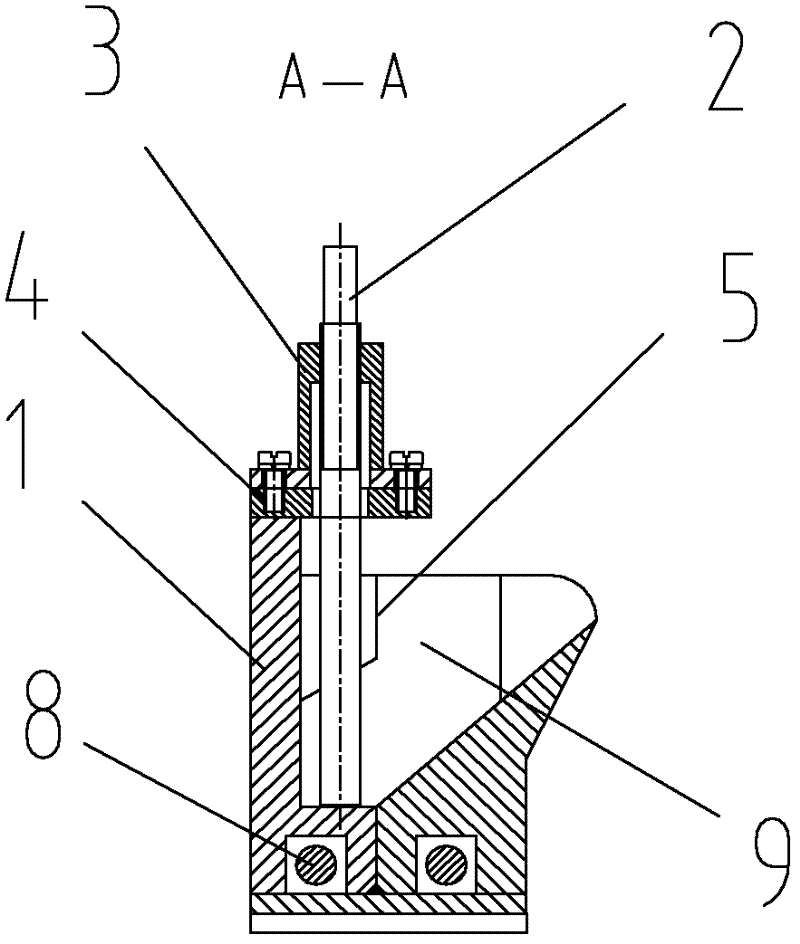

[0024] The automatic pouring system for indium ingots requires single-cycle mass production, and the precise standard for each indium ingot is 1kg±80g. see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The melt casting main body 1 is provided with a left transmission shaft 6 and a right transmission shaft 12 supported by a support, and the melt casting main body 1 is provided with a plurality of independent quantitative pouring grooves 9 separated by a partition 5, and the partition 5 The height is lower than the melt pouring main body 1 to form a gap to communicate between adjacent quantitative pouring grooves 9, the first quantitative pouring groove 9 is connected to the liquid inlet 10, and the last quantitative pouring groove 9 is connected to the overflow port 11, Each quantitative pouring tank 9 is fixed with an adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com