Spot welding system for electrode plates of power battery pack

A technology for power battery packs and electrode sheets, which is applied in the direction of resistance electrode holders, electrode characteristics, resistance welding equipment, etc., can solve the problems of low welding efficiency, low welding pass rate, and increased equipment costs, and achieve improved work efficiency and high welding efficiency. Quality, low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

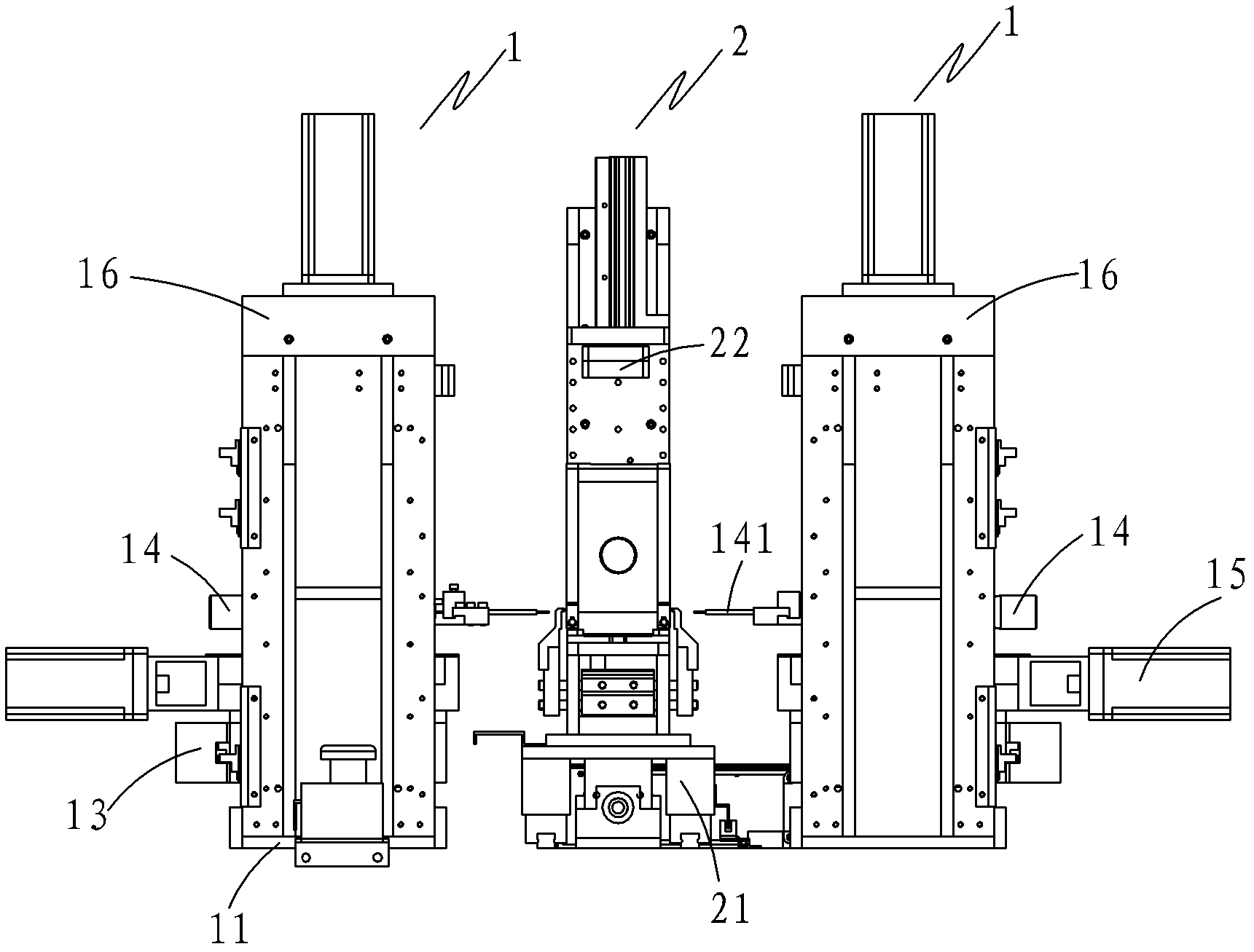

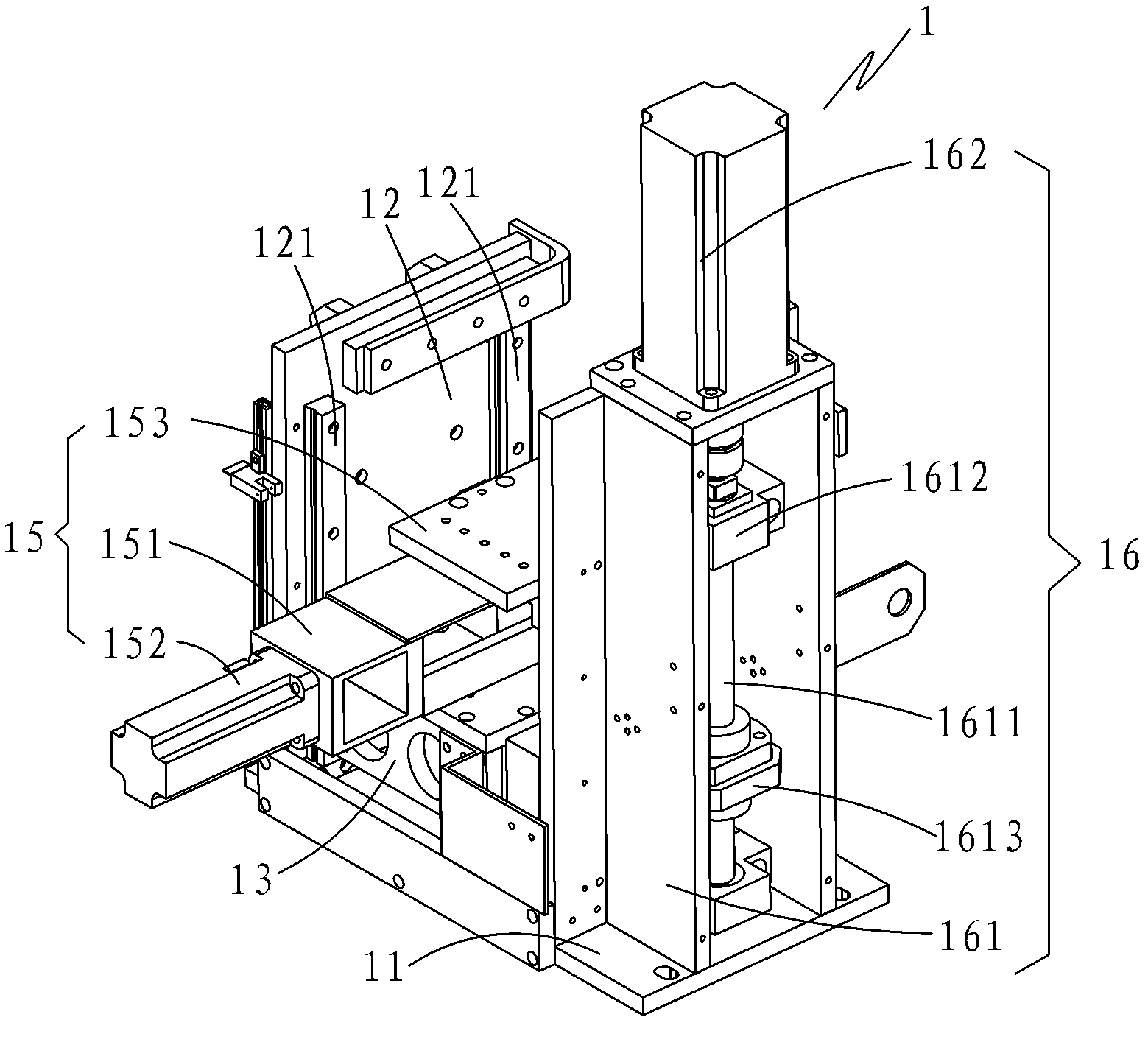

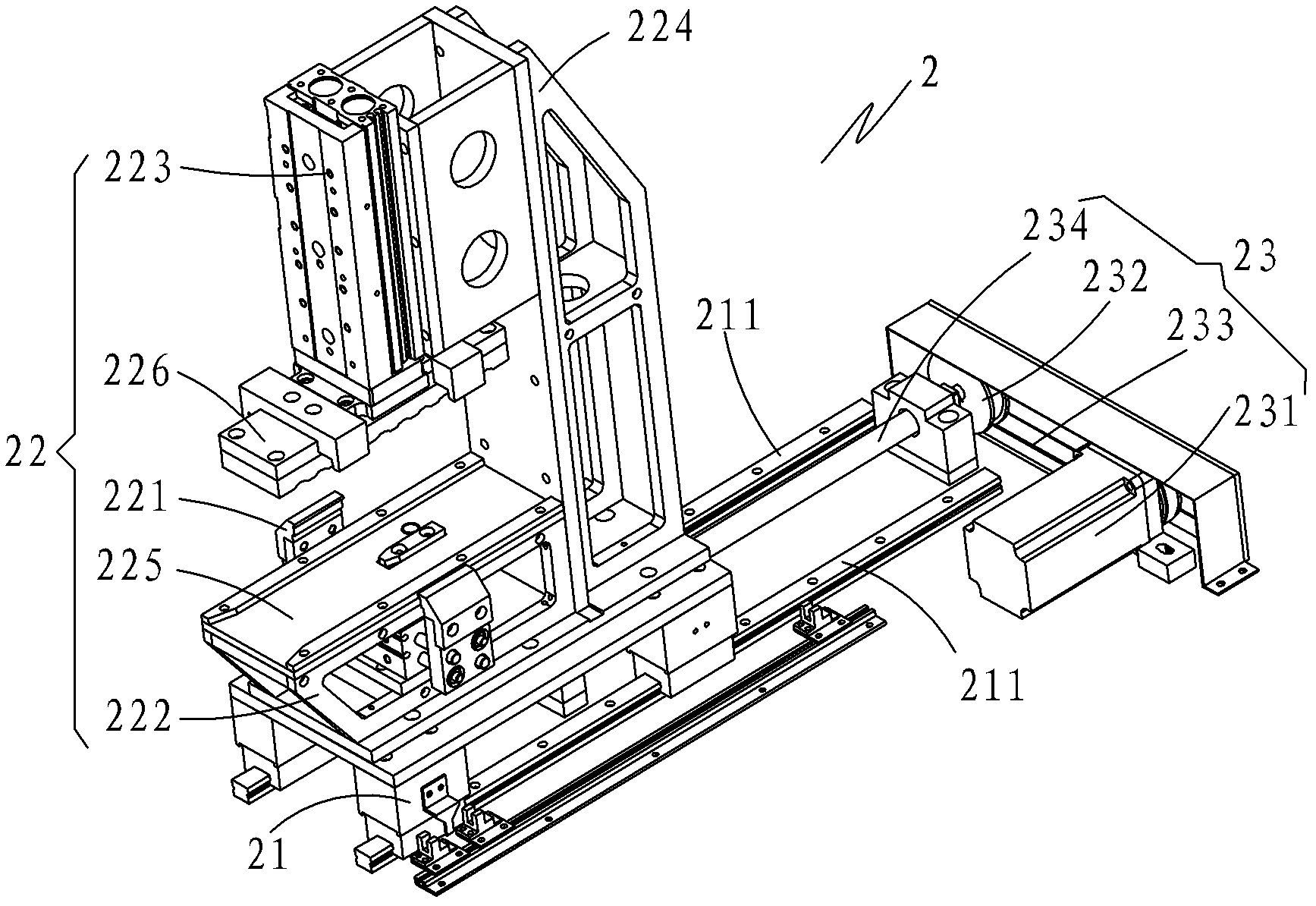

[0019] see figure 1 As shown, a power battery pack electrode piece spot welding system includes a group of spot welding devices 1 and spot welding fixture clamping devices 2 arranged side by side, and the spot welding device 1 and spot welding fixture clamping device 2 are all connected with each other. The PLC (not shown) of the system is electrically connected and the spot welding fixture clamping device 2 is arranged in the middle of the group of spot welding devices 1; Welding mechanism 14, the X-axis motion mechanism 15 that makes described elevating table 13 longitudinally move and the Z-axis motion mechanism 16 that makes described spot welding mechanism laterally move; Described side plate 12 fronts are vertically provided with two guide rails 121 in parallel, so The side plate 12 is arranged vertically to the bottom plate 11; the Z-axis motion mechanism 16 is vertically arranged on the bottom plate 11 and corresponds to the side plate 12; the lifting platform 13 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com