Blade welding clamp for impeller assembly

A technology for welding fixtures and blades, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor positioning accuracy of blades, difficult welding, and low welding efficiency, so as to facilitate welding and improve welding work efficiency , Improve the efficiency of welding wages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

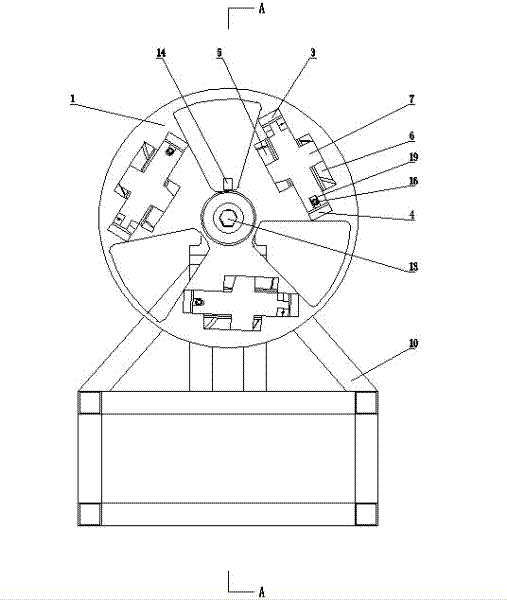

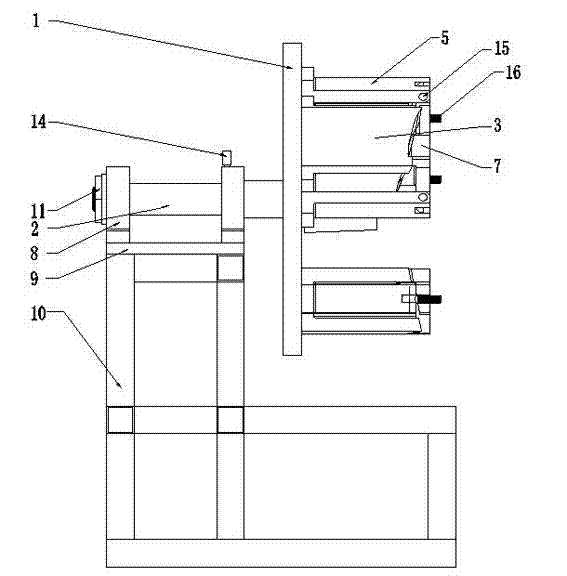

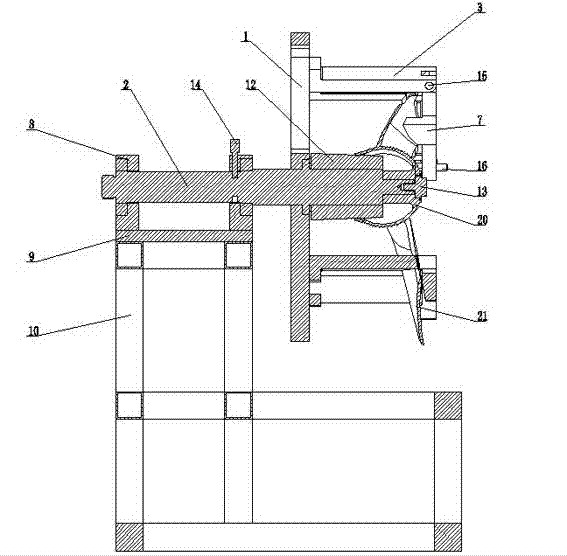

[0011] See figure 1 , figure 2 , image 3 , which includes a fixture base plate 1, on which a positioning mandrel 2 is fixed, on which a blade positioning and clamping structure is installed, three blade positioning and clamping structures are provided, and the three blade positioning and clamping structures are respectively arranged along the blade The direction of rotation is evenly arranged on the base plate 1 of the fixture. The blade positioning and clamping structure includes two L-shaped brackets 3, 4 and two positioning blocks 5, 6. The two L-shaped brackets 3, 4 are installed on the fixture bottom plate 1 facing away from each other in parallel. The upper ends of the two brackets 5, 6 pass through the cross The two positioning blocks 5 and 6 are respectively fixed on the outer sides of the two brackets 3 and 4 in parallel, and the lower surface of the cross-shaped pressing plate 7 and the upper surfaces of the two positioning blocks 5 and 6 cooperate with the profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com