Sealing method for degassing tube

A technology for degassing tubes and clamping flats, which is applied in the field of semiconductor manufacturing, and can solve problems such as gaps, inability to maintain the vacuum degree of the vacuum package, and air leakage, and achieve the effects of simple process, guaranteed vacuum degree, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

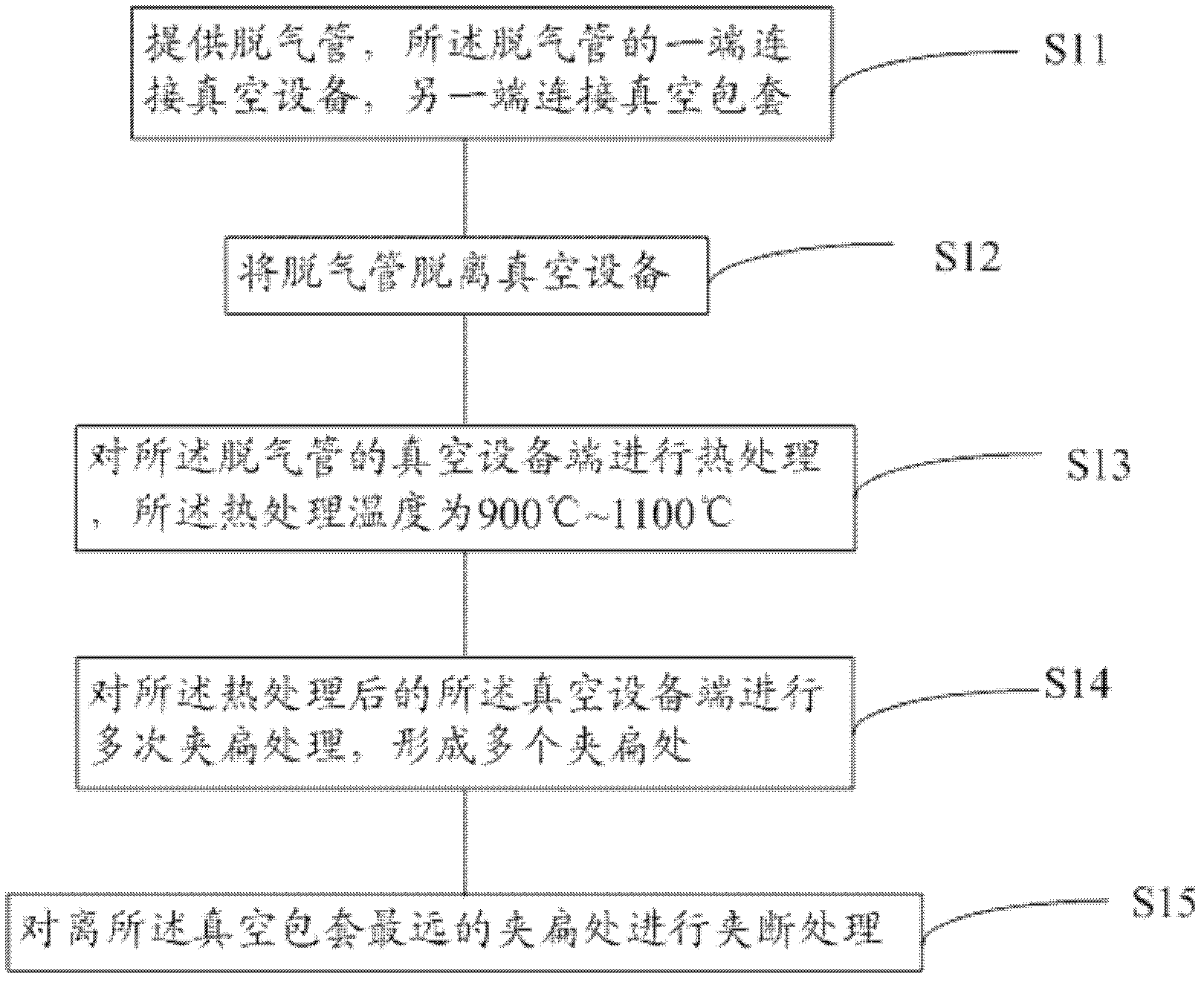

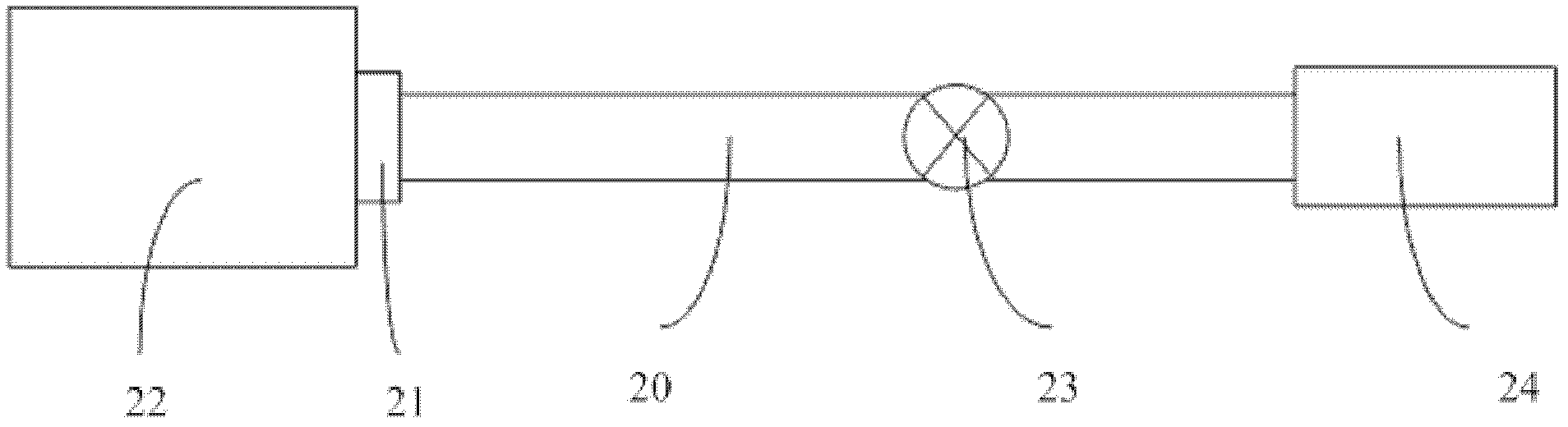

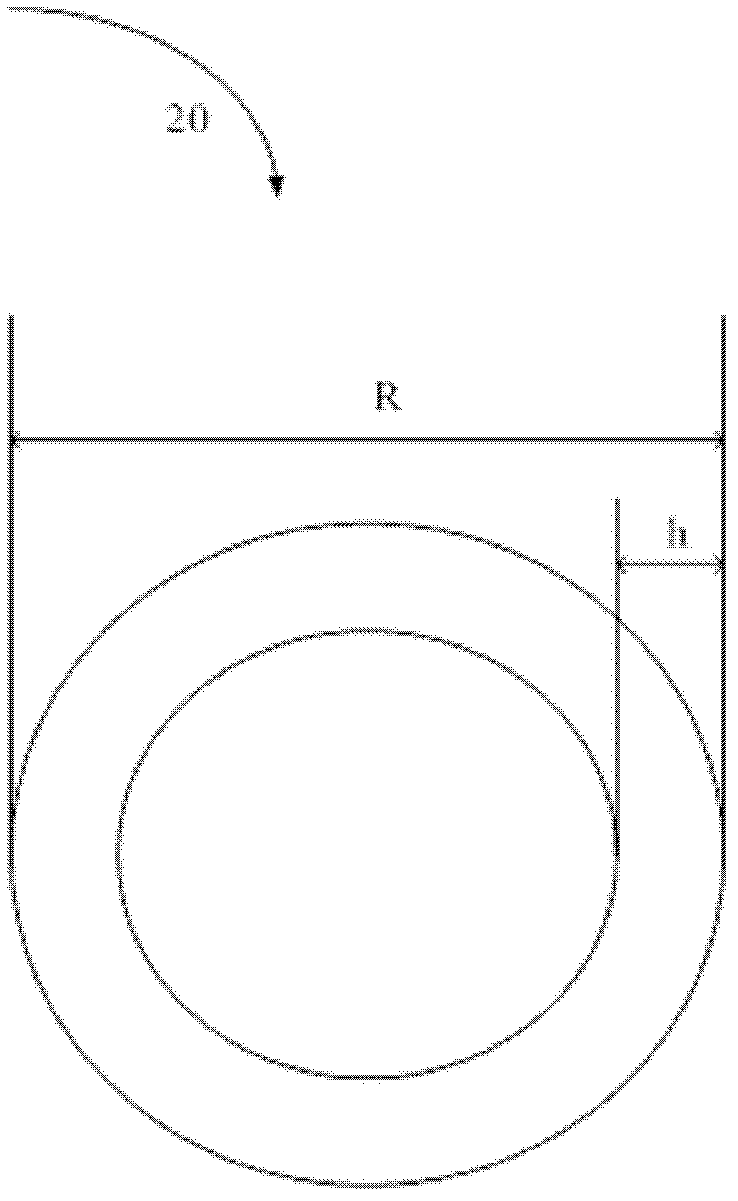

[0033] The invention provides a method for sealing a degassing tube, such as figure 1 , to solve the technical problems that the vacuum degree in the vacuum bag cannot be maintained and the gaps and air leakage appear in the subsequent bag cooling, storage and transportation process, and has the advantages of simple process, convenient operation and good sealing effect. The degassing tube sealing method comprises:

[0034] Step S11, providing a degassing tube, one end of the degassing tube is connected to a vacuum device, and the other end is connected to a vacuum bag.

[0035] Step S12, disconnect the degassing tube from the vacuum equipment.

[0036] Step S13, performing heat treatment on the vacuum equipment end of the degassing tube, the heat treatment temperature being 900°C-1100°C.

[0037] Step S14 , performing multiple clamping treatments on the vacuum equipment end after the heat treatment to form multiple clamping places.

[0038] Step S15 , performing pinch-off p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com