Main shaft supporting structure of centerless grinder for grinding valve lock groove

A centerless grinding machine and spindle support technology, which is applied to machine tools, grinding machines, grinding/polishing equipment, etc. designed for grinding the rotating surface of workpieces, can solve the problems of low spindle rotation accuracy, high power consumption, and large starting torque, etc., to achieve The starting torque is small, the power consumption is small, and the effect of improving the rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

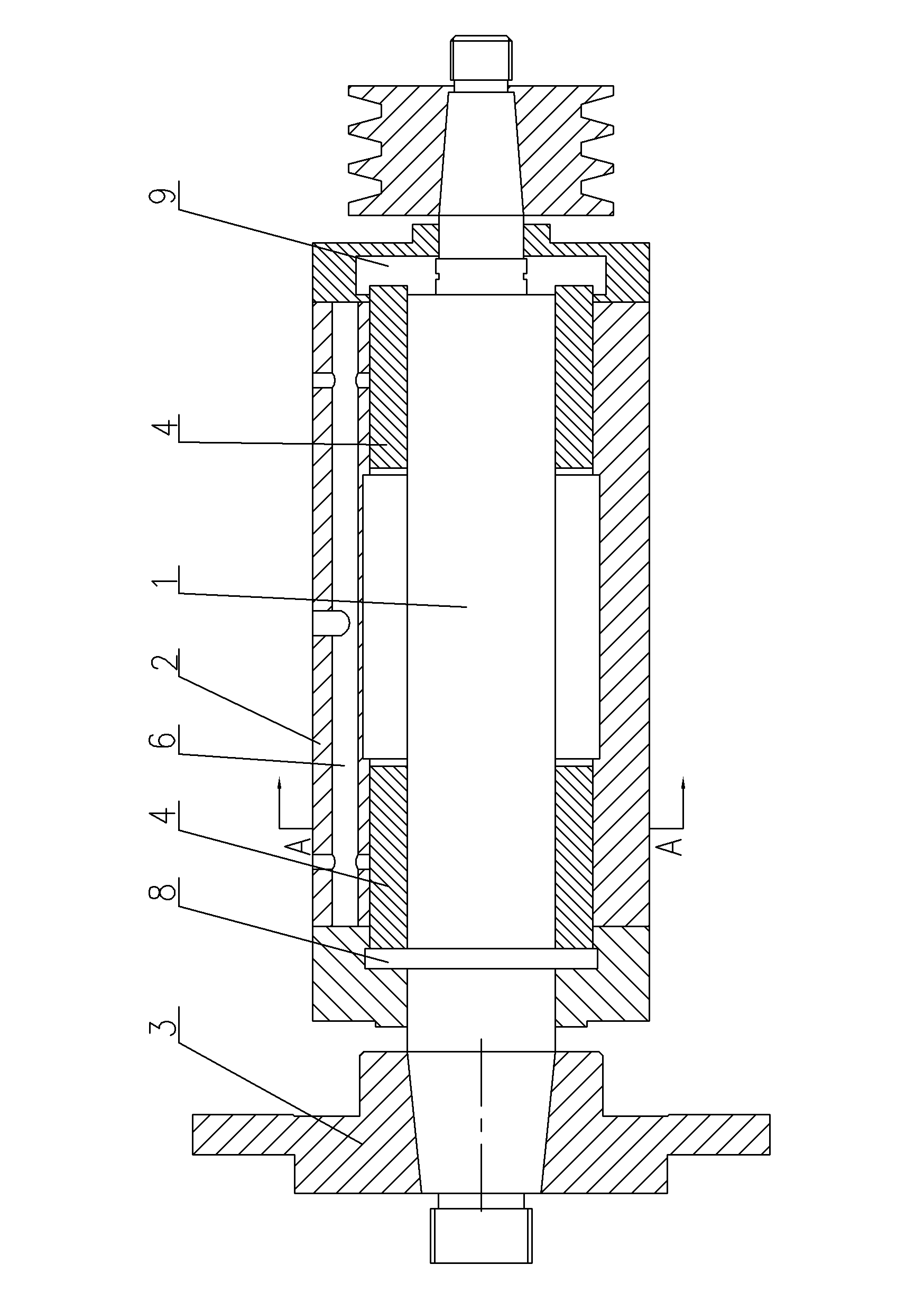

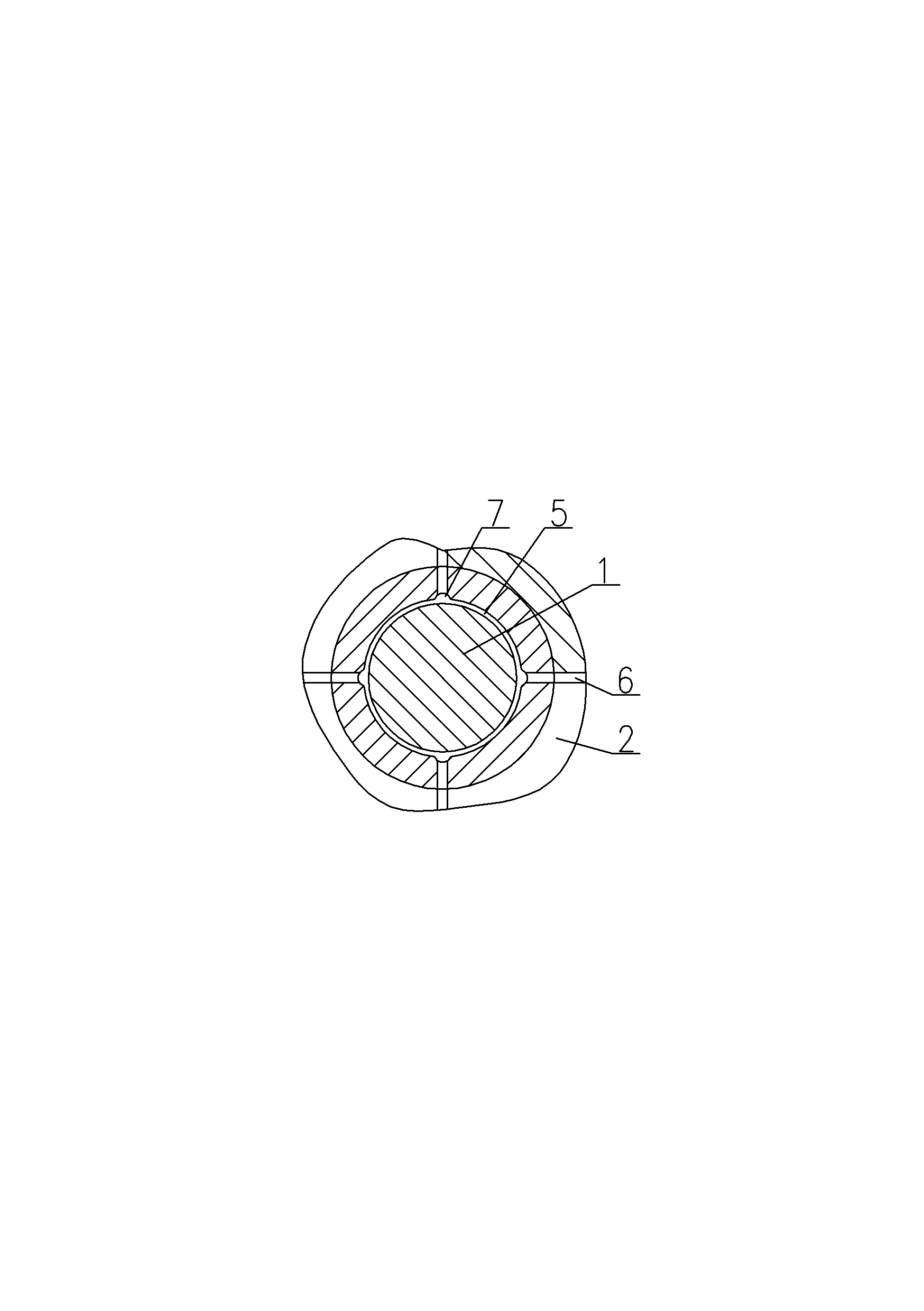

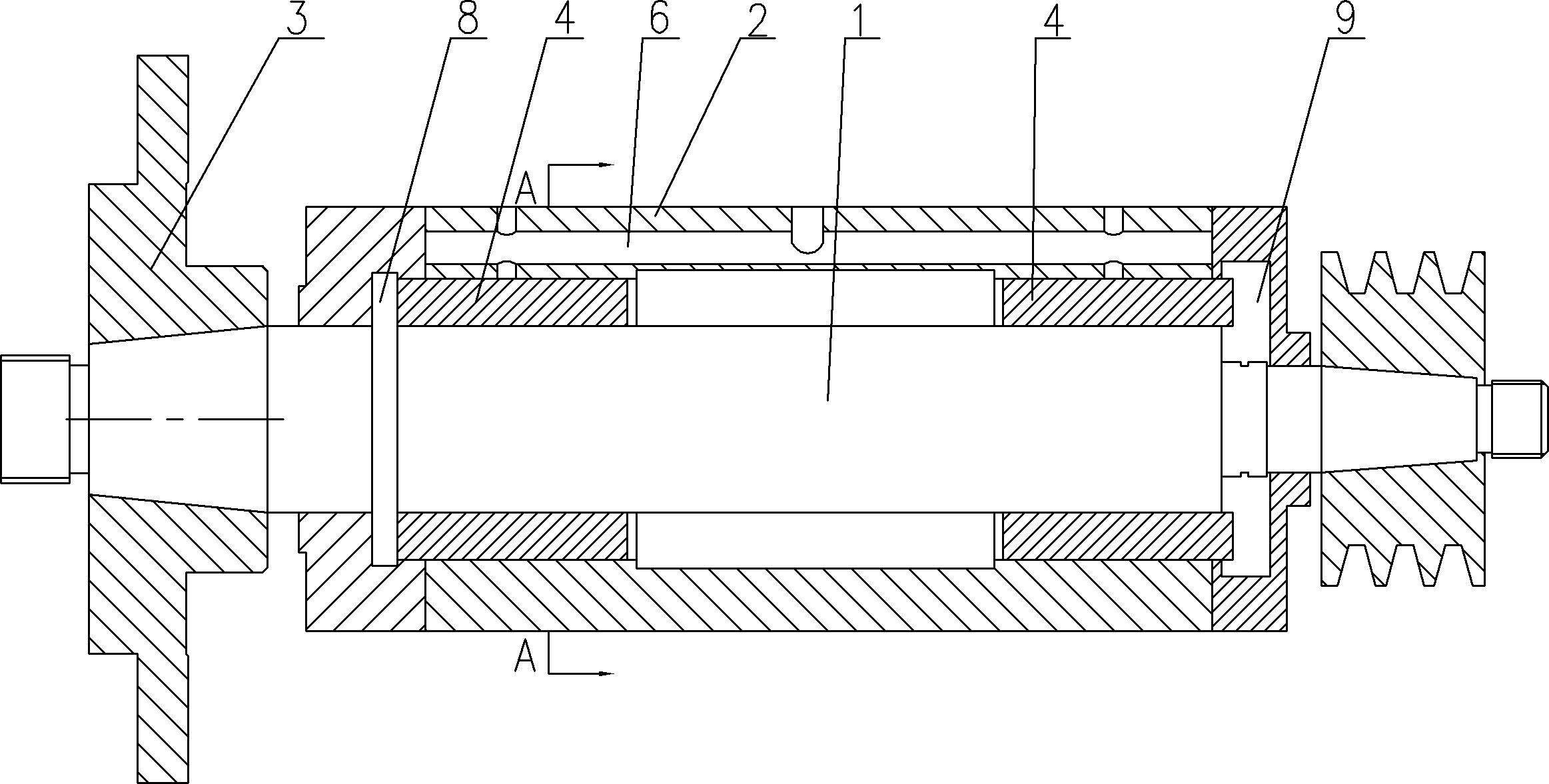

[0009] See figure 1 , figure 2 , which includes a main shaft 1, a main shaft housing 2, and a grinding wheel chuck 3. The end of the main shaft 1 is fitted with a grinding wheel chuck 3. The main shaft 1 runs through the main shaft housing 2. Both ends of the main shaft housing 2 are provided with hydrostatic oil film bearings 4. The main shaft 1 Through the inner hole 5 of the dynamic and static pressure oil film bearing 4, there is an oil passage 6 in the main shaft housing 2, and the oil passage 6 is connected to the internal oil chamber 7 of the dynamic and static pressure oil film bearing 4, and the internal oil chamber 7 is evenly distributed in the interior of the dynamic and static pressure oil film bearing 4 The inner wall of the hole 5, the inner oil chamber 7 wraps the outer edge of the main shaft 1. Both ends of the main shaft 1 are fitted with a front oil block 8 and a rear oil block 9 respectively. The front oil block 8 fits the front end of the dynamic and sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com